Two-stage folding type balance mechanism of pipe sling

A balancing mechanism and folding technology, applied in cranes and other directions, can solve the problems of large counterweight weight and overall machine weight, low lifting capacity per unit weight, high manufacturing and transportation costs, and achieve small counterweight weight, compact structure, The effect of small cylinder load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

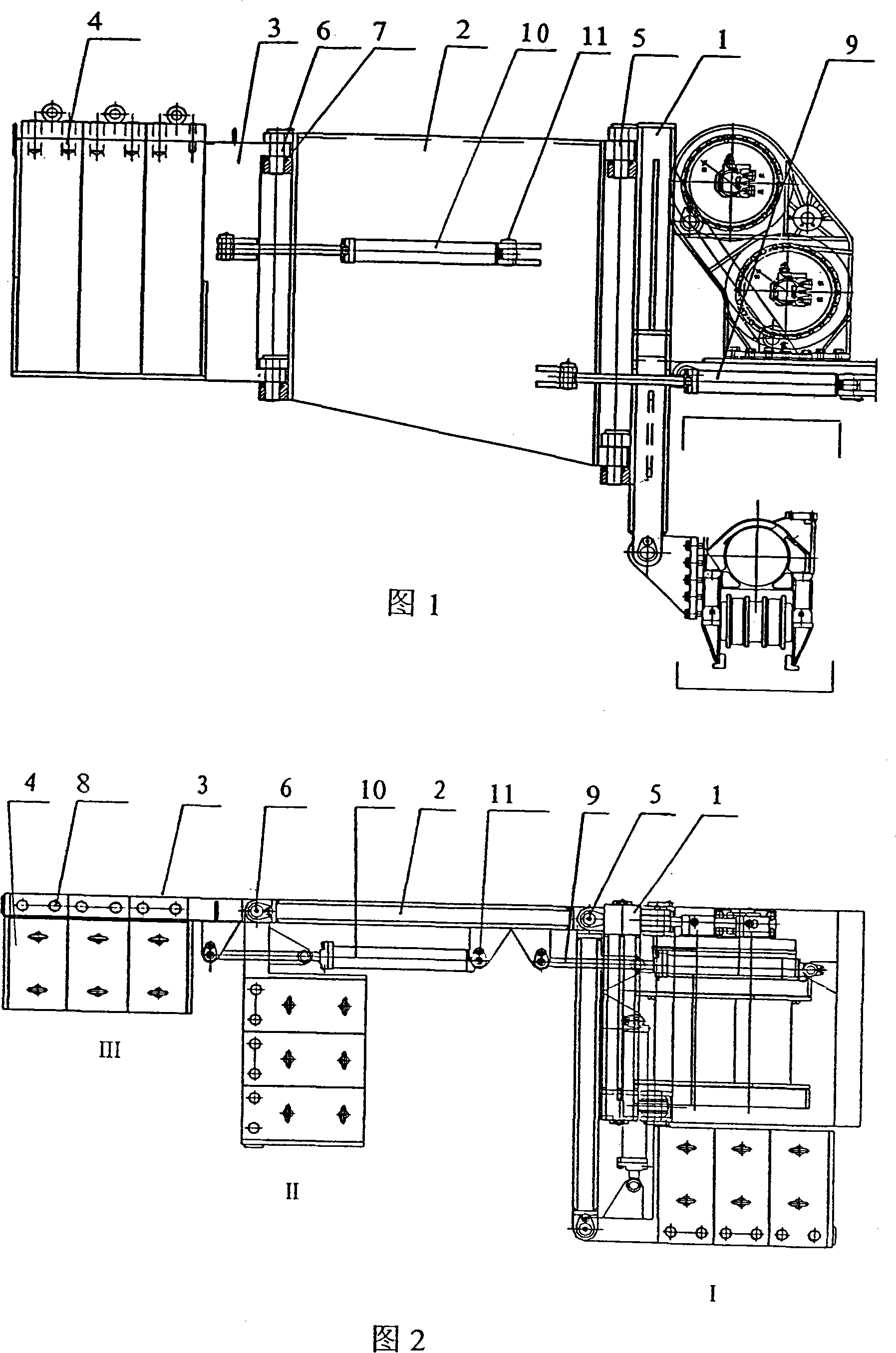

[0011] Referring to Fig. 1 and Fig. 2, the counterweight support 1 is fixed together with the frame, a primary cantilever 2 is hinged with the counterweight support 1 through the primary cantilever pin shaft 5 and a thrust bearing 7, and a secondary cantilever 3 is provided to pass through the secondary The cantilever pin 6 and the thrust bearing 7 are hinged with the first-stage cantilever 2, and each counterweight 4 is connected with the second-stage cantilever 3 through two counterweight pins 8; frame connection, the other end is connected with the primary cantilever 2 through the oil cylinder pin 11; there is a secondary oil cylinder 10, one end is connected with the primary cantilever 2 through the oil cylinder pin 11, and the other end is connected with the secondary cantilever 3 through the oil cylinder pin 11; The axes of the primary cantilever pin 5, the secondary cantilever pin 6, the counterweight pin 8 and the oil cylinder pin 11 are vertical. The positions I, II, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com