Powerful chuck mechanism

A powerful and rack-based technology, applied in the direction of clamps, manufacturing tools, etc., can solve the problems of poor speed synchronization of the forming jaws on both sides, inability to monitor the stability of force and displacement values, and difficulty in ensuring forming quality, and achieve easy maintenance. , saving installation space and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

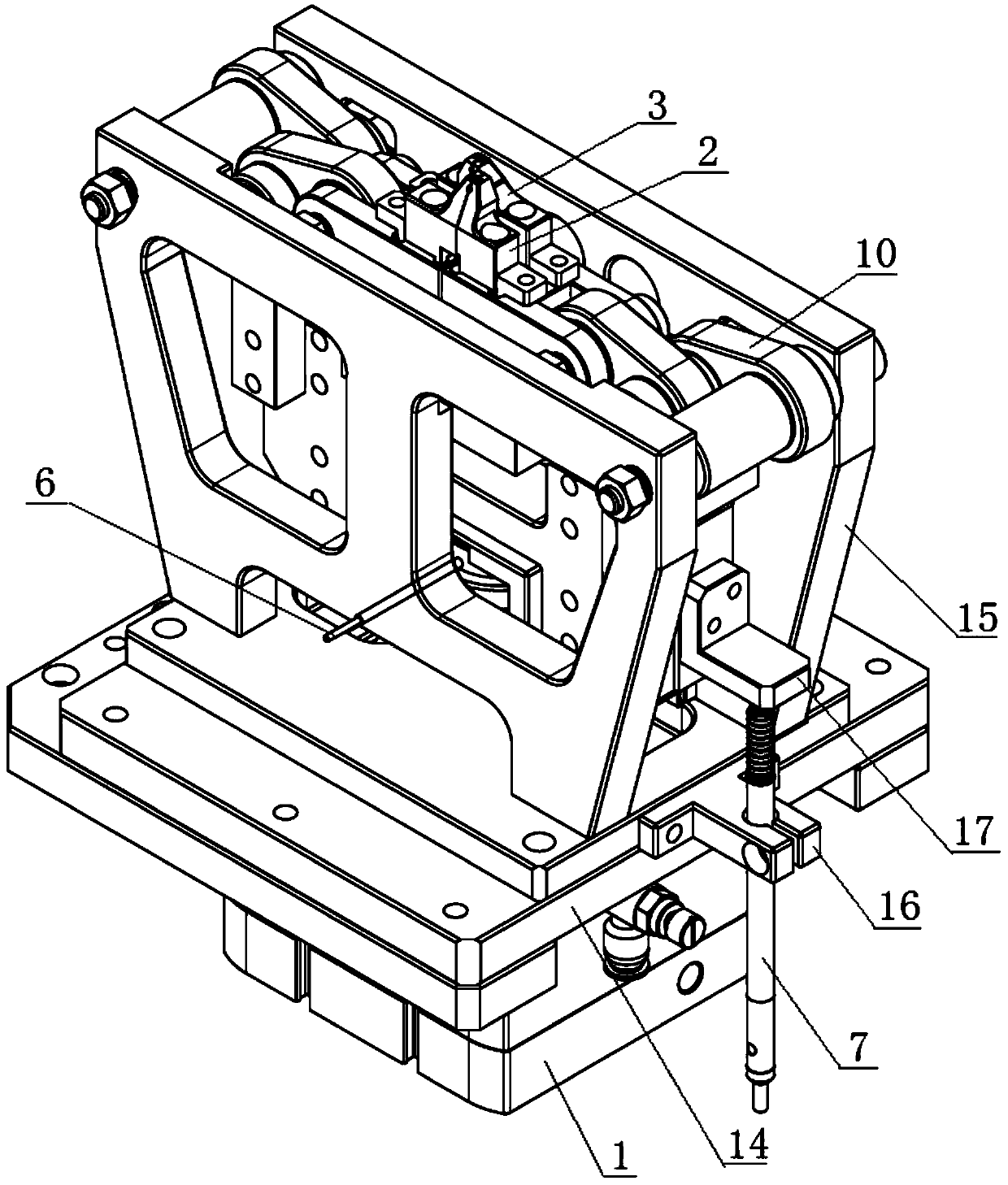

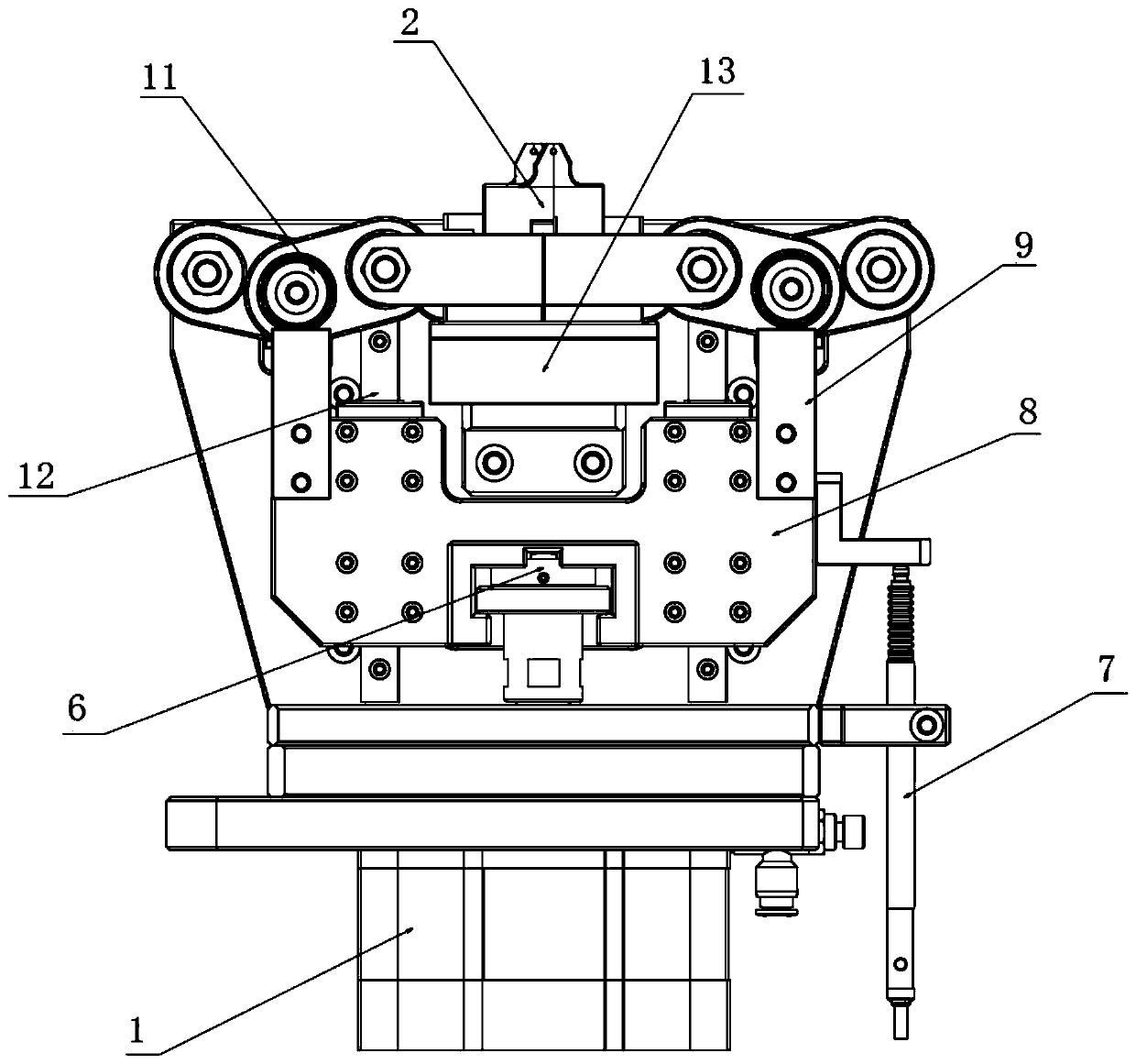

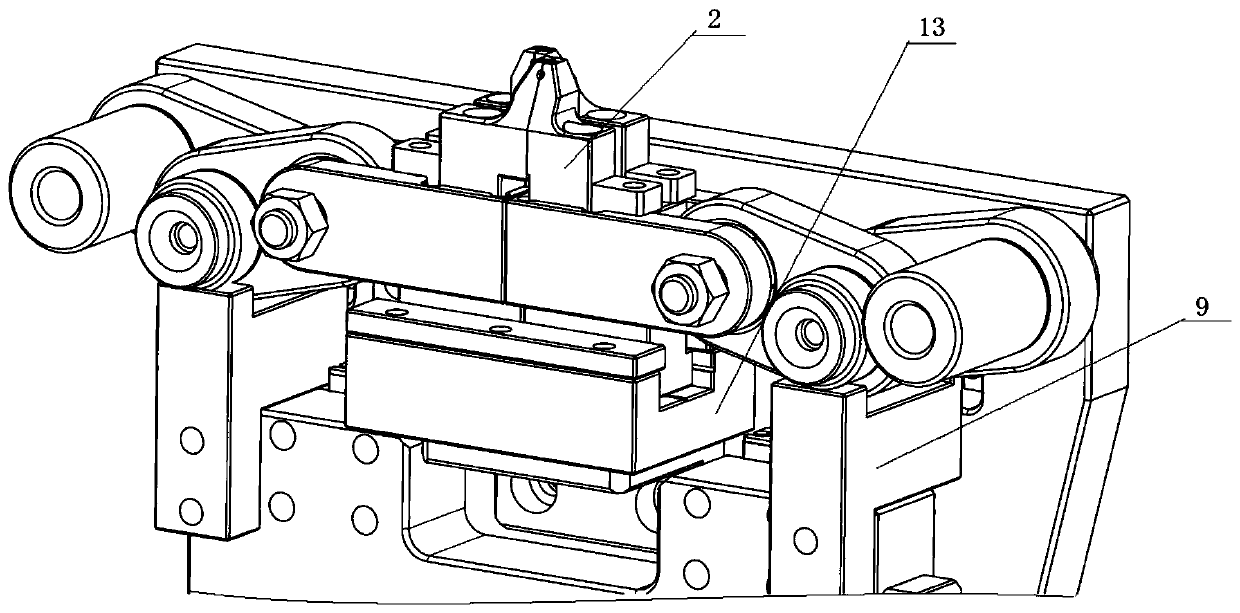

[0029] see Figure 1~4 As shown, a kind of powerful collet mechanism provided by the present invention comprises:

[0030] The frame is used to support the whole powerful chuck mechanism;

[0031] A cylinder 1, whose cylinder body is fixed on the bottom of the frame, and whose cylinder rod is vertically connected to the bottom center of the transmission part;

[0032] Two sets of forming jaws, which move symmetrically on the top of the frame, realize the two sets of forming jaws approaching or moving away from each other through the transmission parts, each set of forming jaws includes two first sub-jaws 2 and second The sub-claw 3, one side of the first sub-claw 2 and the second sub-claw 3 form a semicircular wire harness placement groove, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com