Differential type pneumatic angle pedestal valve

A pneumatic angle seat valve, differential technology, applied in the direction of lift valve, valve detail, valve device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

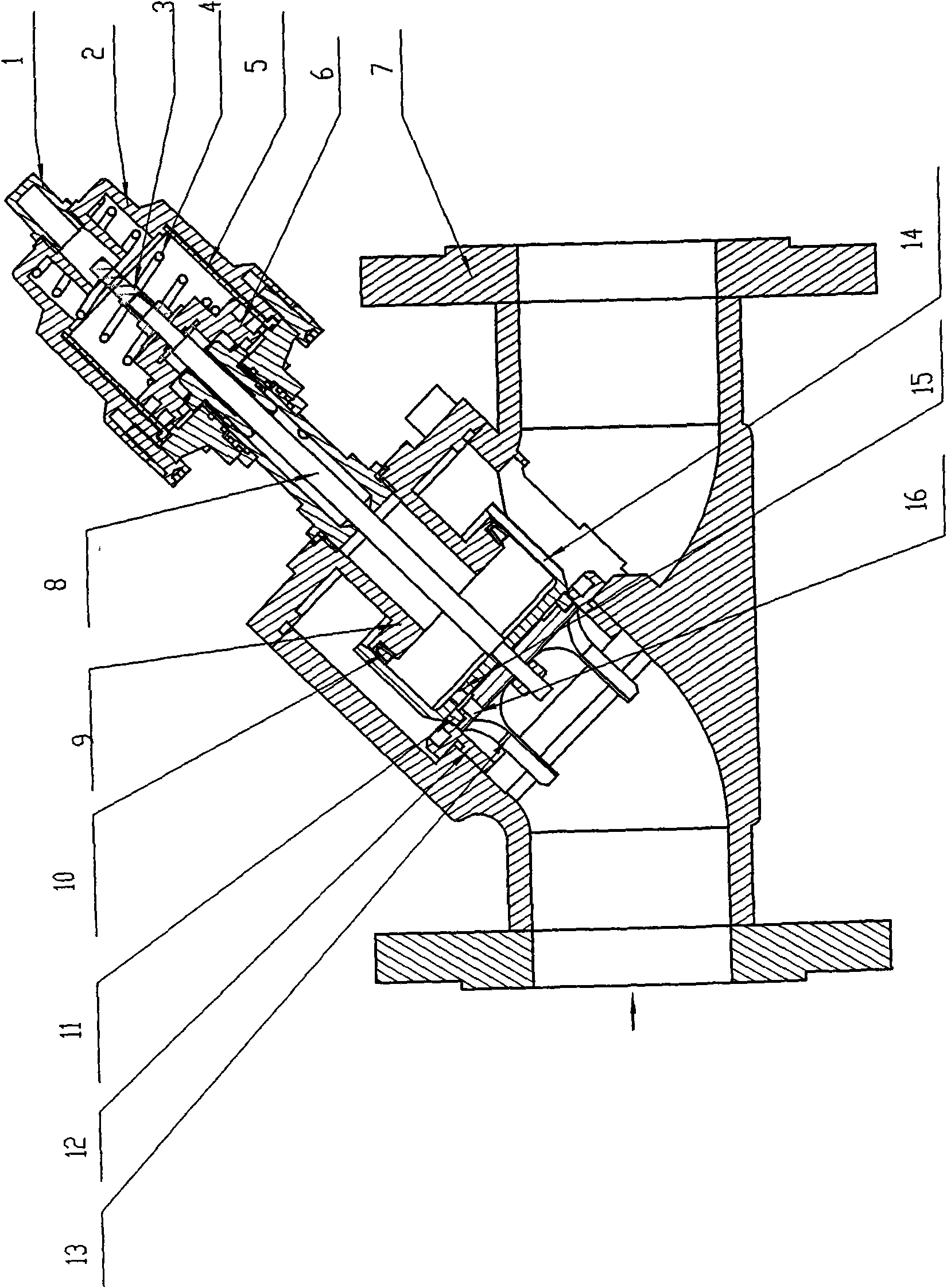

[0008] Such as figure 1 As shown, the valve has valve body 7, piston 6, plastic cylinder barrel 5, return spring 4, indicator 3, executive cylinder 2, transparent observation window 1, piston rod 8, differential fixed piston 9, differential movable cylinder 14, It is composed of Pansysel sealing ring 10, valve seat sealing ring 11, valve seat 12, valve seat guide head 13, balance hole A16, and balance hole B15. There is a differential movable cylinder and a differential fixed piston inside the valve seat, one end of the differential movable cylinder is connected with the differential fixed piston, and the other end is connected with the guide head of the valve seat; a balance hole B is provided on the differential movable cylinder to balance with the guide head Hole A communicates.

[0009] The diameter of the sealing surface of the valve is DN1, and the diameter of the differential movable cylinder is DN2. The characteristics of the valve are: when a medium flows in (assumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com