Multiple arms telescopic device automatically controlled by single telescopic cylinder

A telescopic oil cylinder and telescopic device technology, which is applied to cranes and other directions, can solve the problems of large difference in the design section of the telescopic arm, complex telescopic structure, and influence on the lifting capacity, so as to achieve strong lifting capacity and versatility, and increase the boom section. The effect of simple area and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

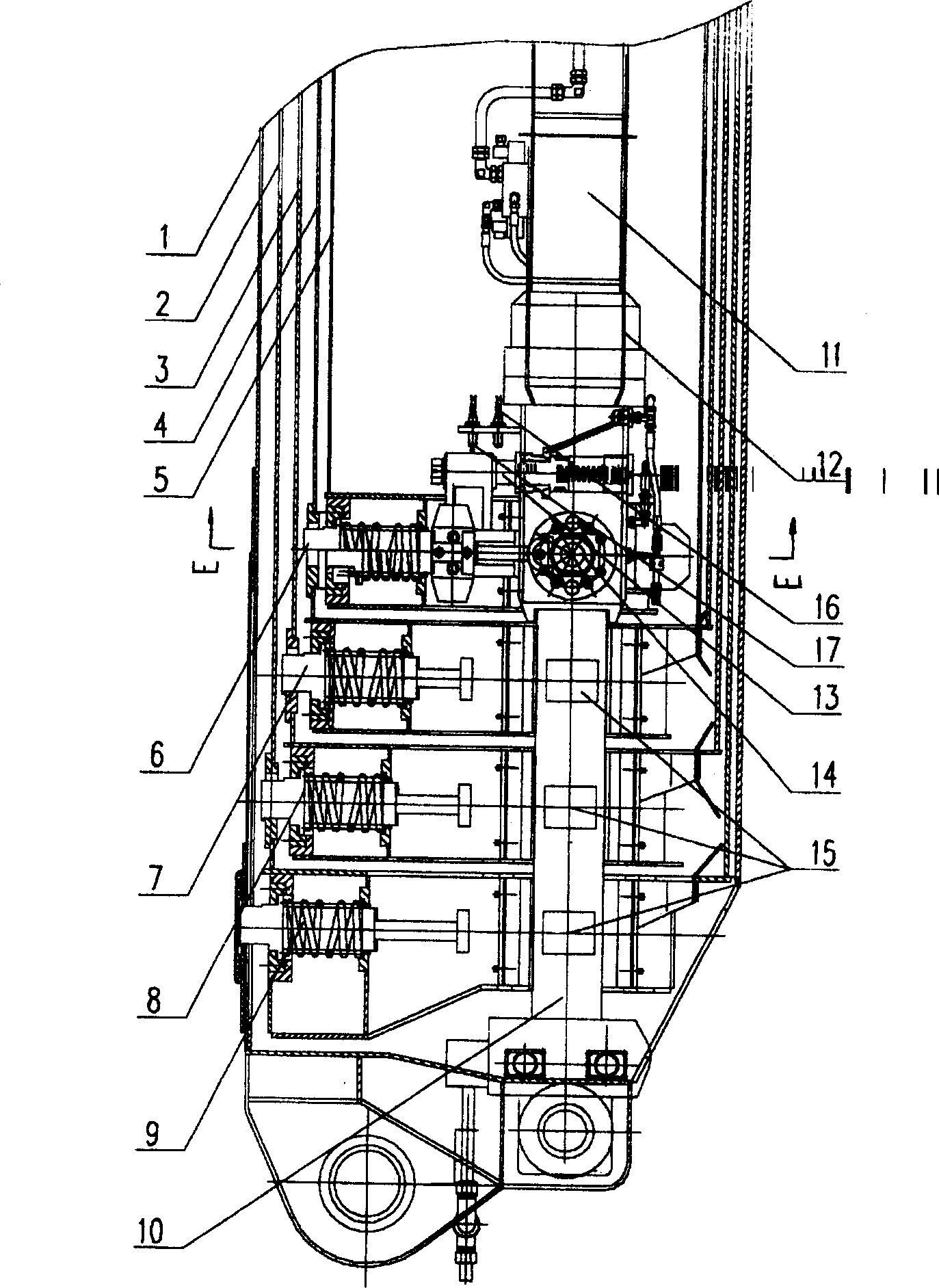

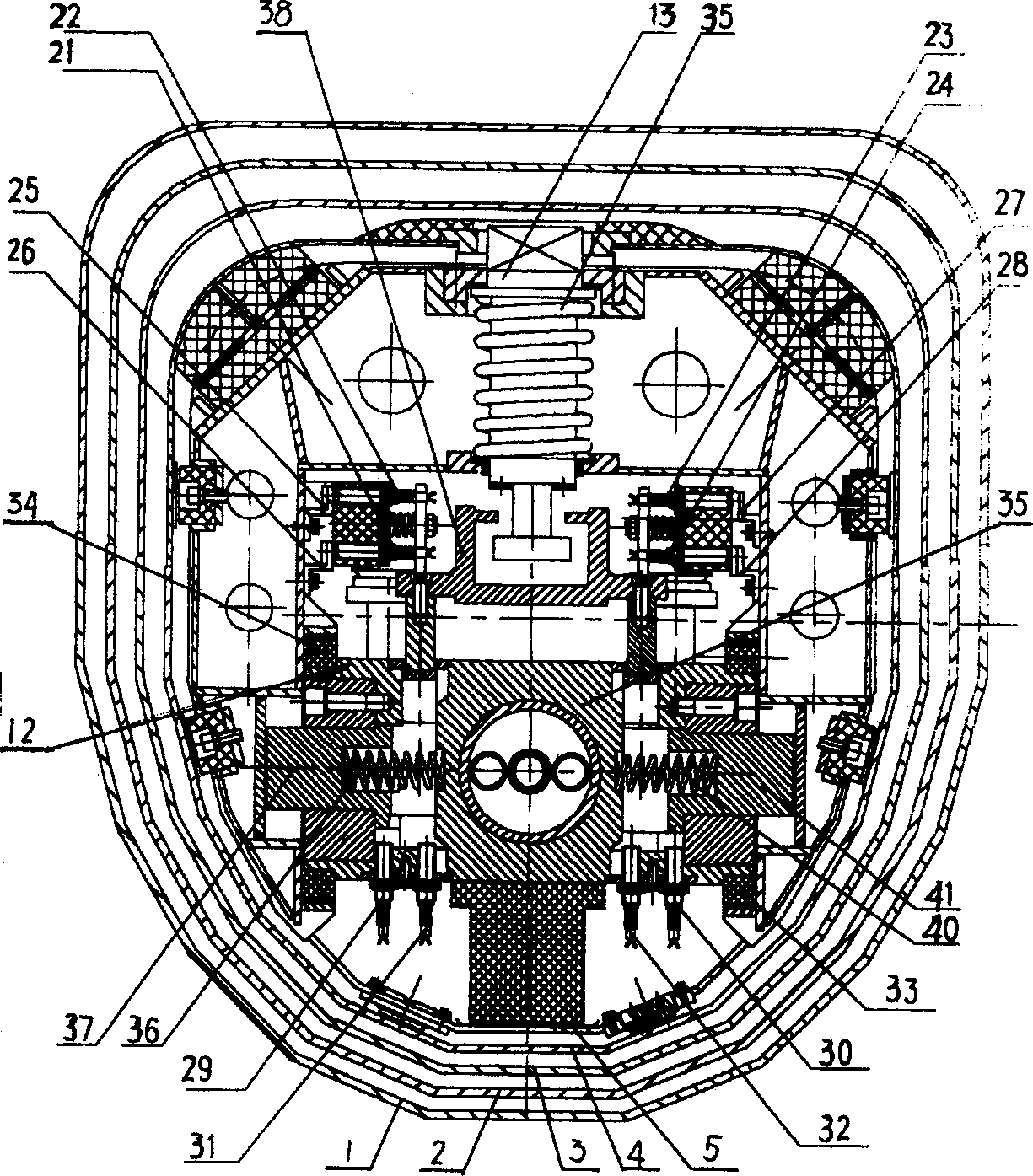

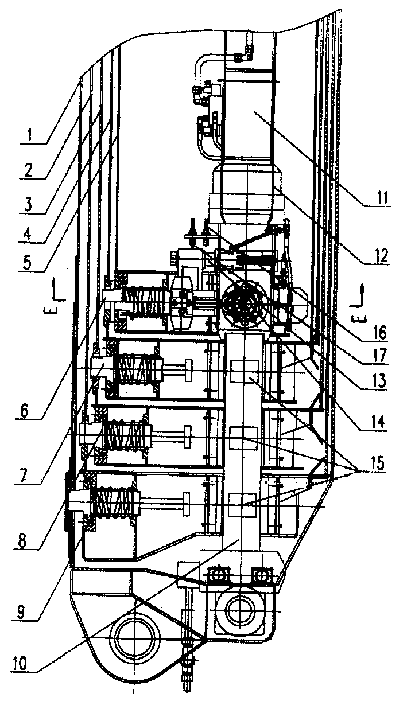

[0008] Embodiment 1: Cylinder pins are connected to the left and right sides of the cylinder head, and an arm pin extraction device is connected to the upper part of the cylinder head. There is a detection switch for detecting its final position near the arm pin extraction device. There is an end position detection proximity switch at the lower end of the pin, and a position detection proximity switch for each arm on both sides of the rear end of each telescopic arm. The upper part of the rear end of the telescopic arm is connected with an arm pin, and a floating telescopic oil cylinder is provided on both sides of the cylinder head and the cylinder barrel. Slideway, the left and right position chute at the rear end of each section of the boom.

[0009] The device includes a basic arm 1, a two-section arm 2, a three-section arm 3, a four-section arm 4, and a five-section arm 5. Except for the basic arm 1, each section arm is connected with a two-section arm arm pin 9 and a thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com