Grab bucket grooving machine for continuous wall

A technology of groove forming machine and wall grab, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, excavation, etc., which can solve the problem that grabs cannot be hoisted or heavy objects, and the structural strength is difficult to be guaranteed. , Boom reset influence and other issues, to achieve the effect of improving the slotting ability and hoisting ability, good operation effect, and improving the stability of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be pointed out that the description and sequence of specific structures in this section are only descriptions of specific embodiments, and should not be considered as limiting the protection scope of the present invention.

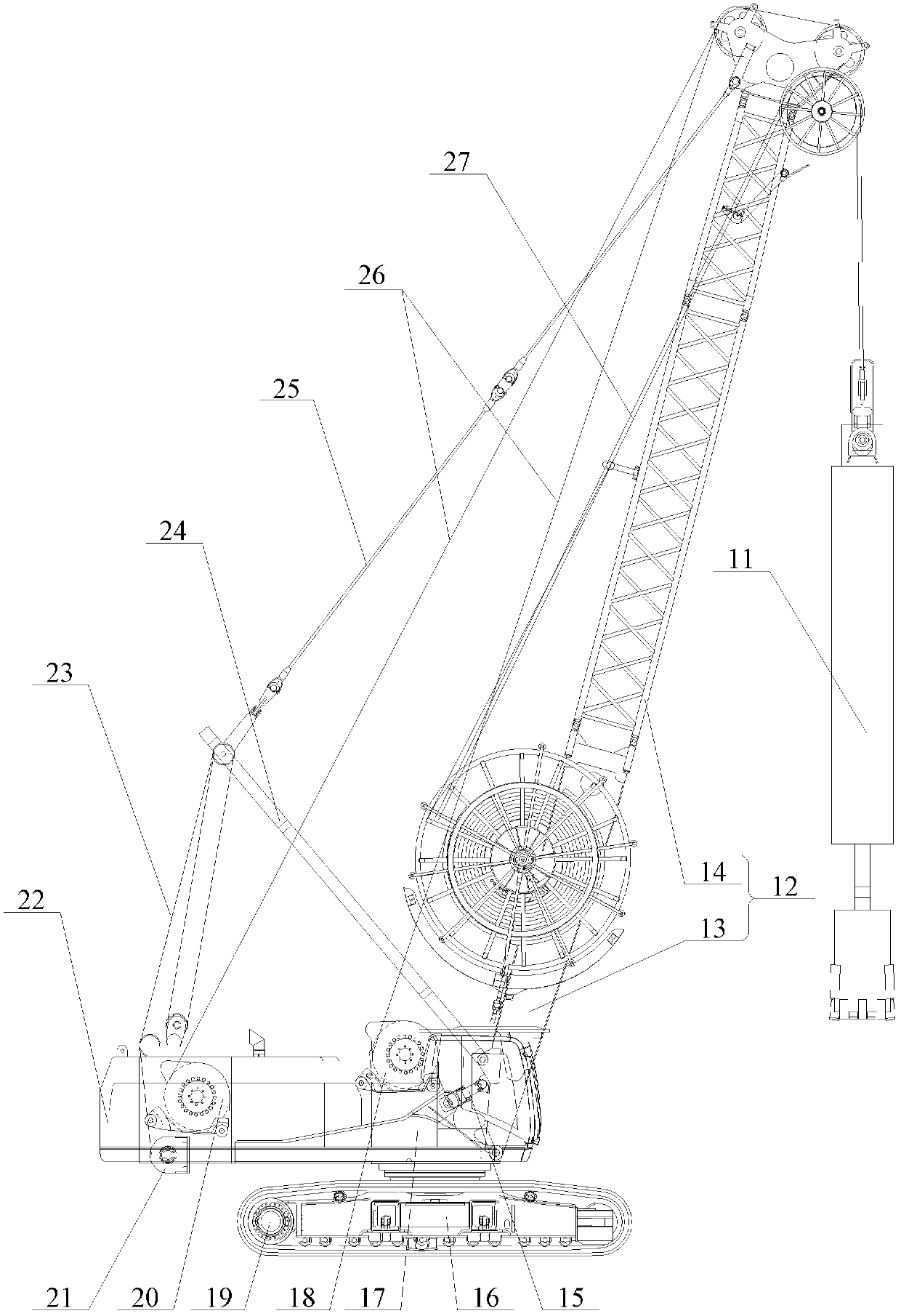

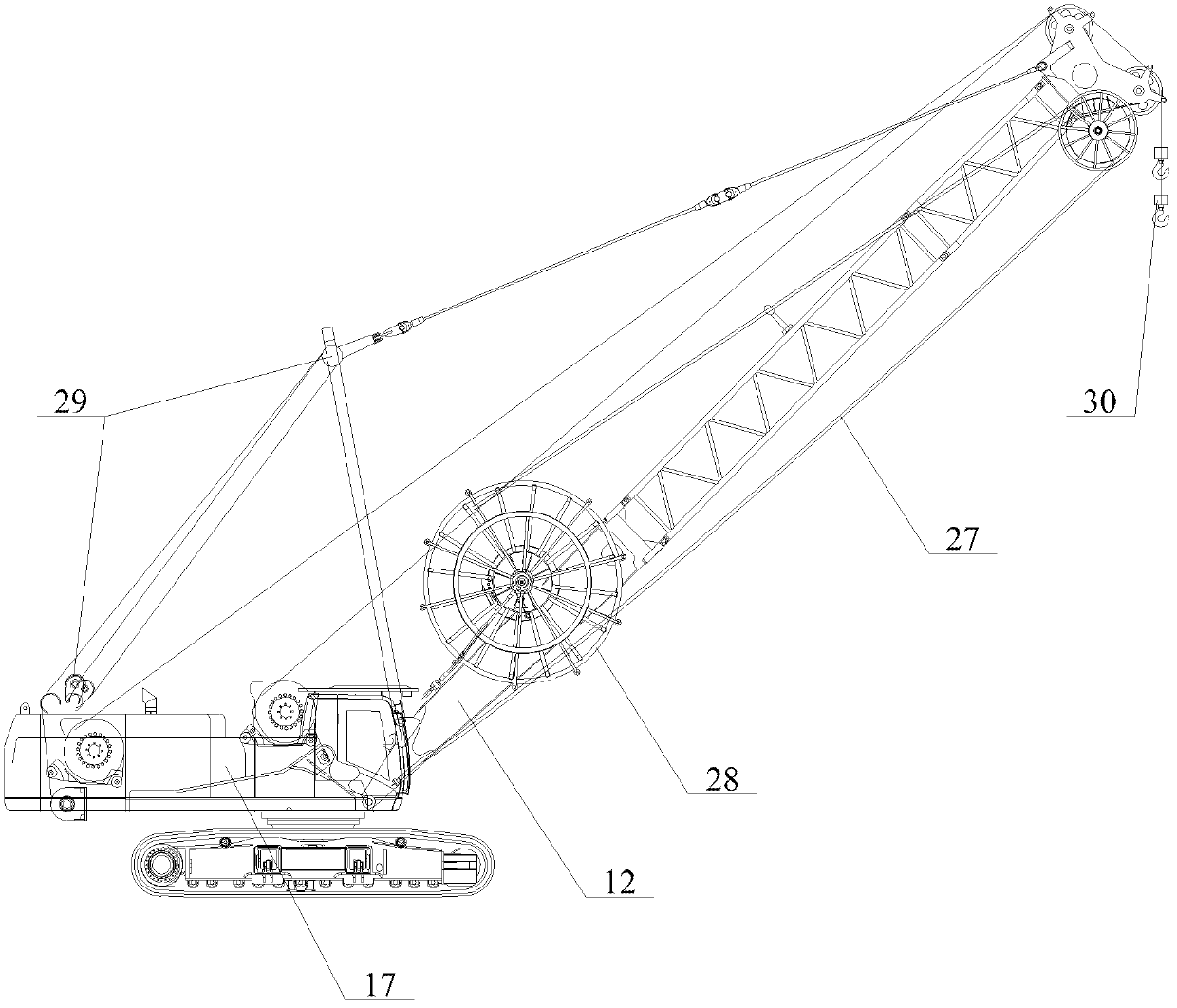

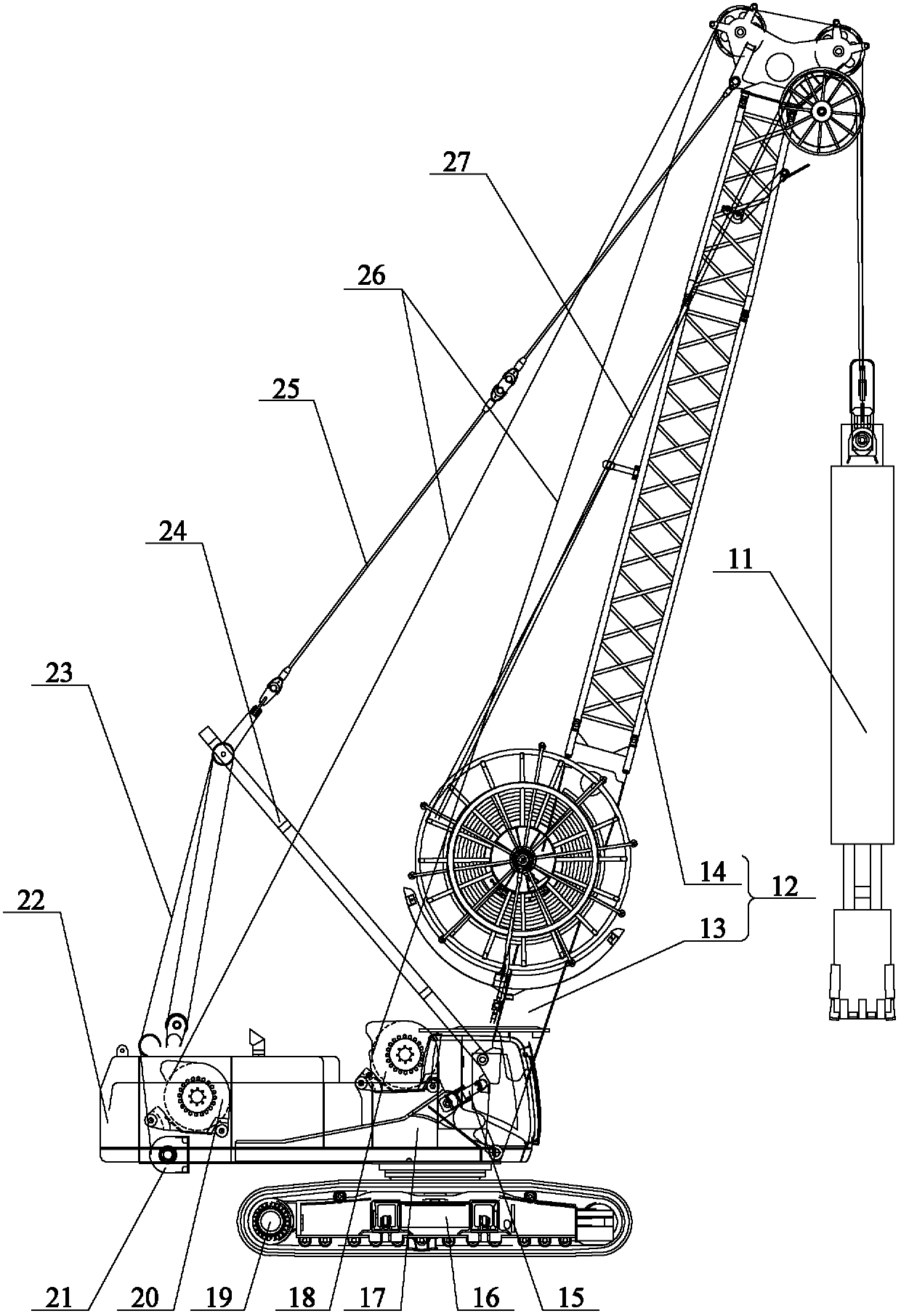

[0033] Please refer to figure 1 and figure 2 . The following will be explained in conjunction with the corresponding drawings according to the needs of the description. It should be pointed out that the orientation words (such as top, bottom, tail, front, etc.) mentioned below are based on the scene when the described object is in a normal working state .

[0034] As shown in the figure, the continuous wall grab groove forming machine mainly includes a chassis 19, an upper body 17, a jib 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com