Hoisting method

A hoisting method and technology for hoisting equipment, which are used in transportation and packaging, load hoisting components, cranes, etc., can solve the problems of short installation construction period, inability to meet, and inability to meet the hoisting requirements of large equipment, and achieve short construction period and hoisting capacity. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

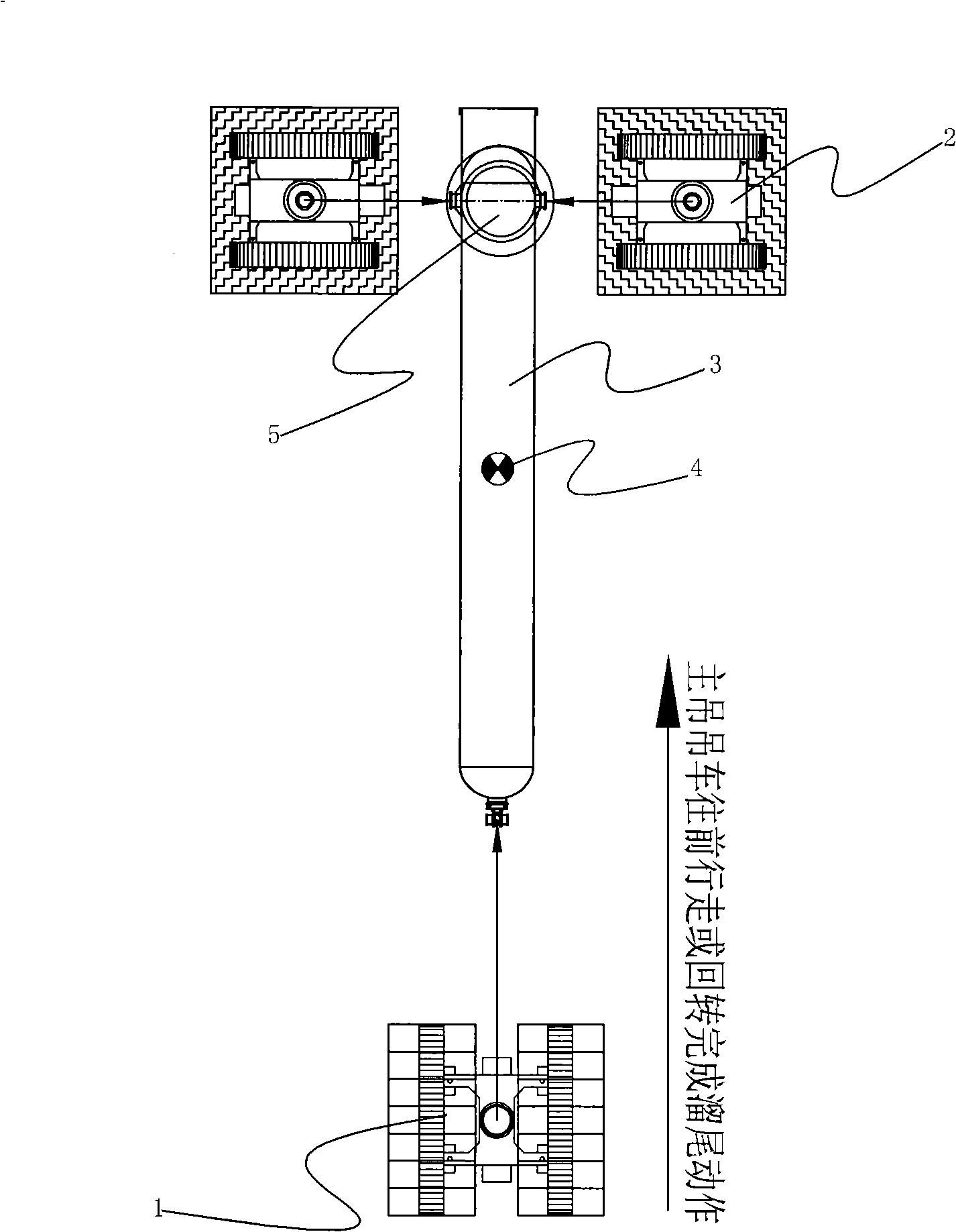

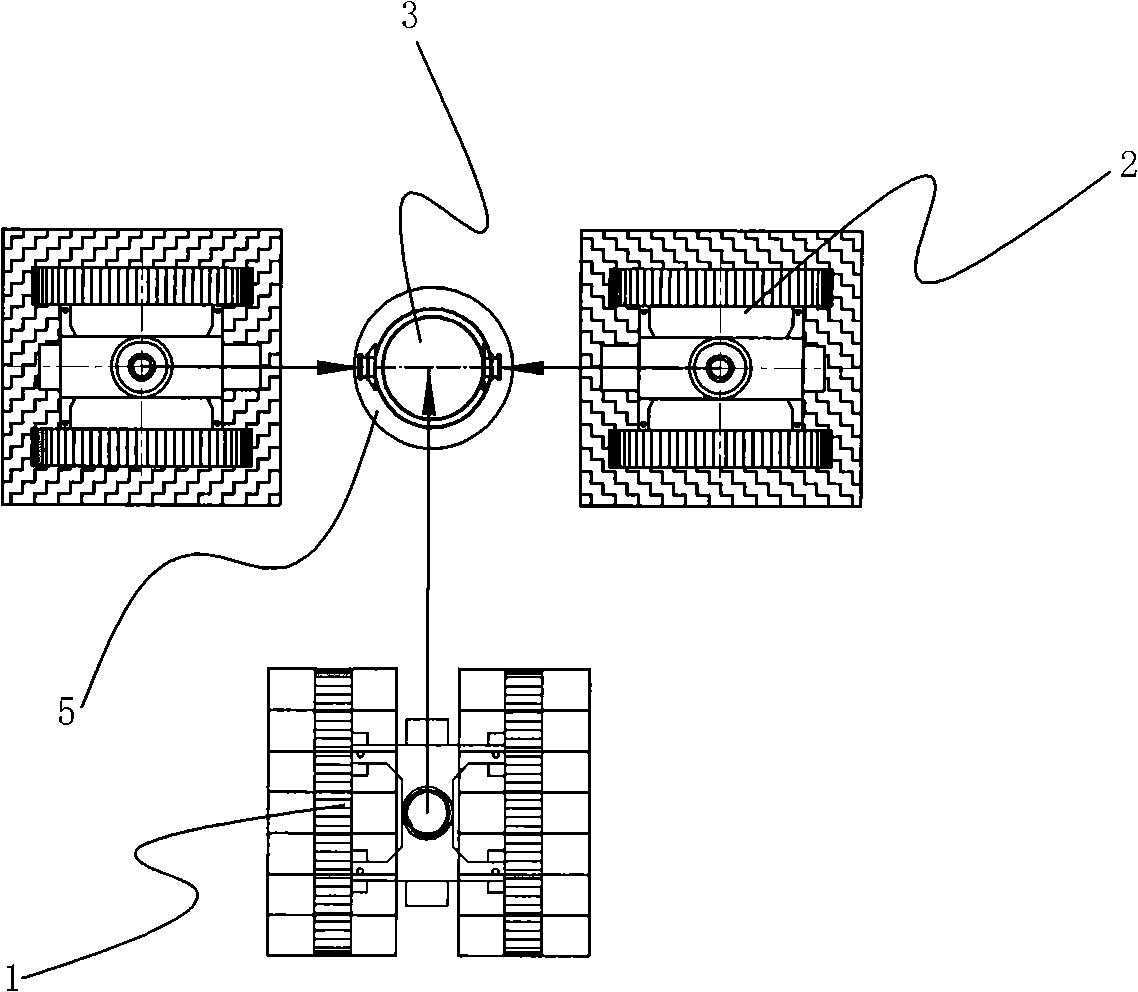

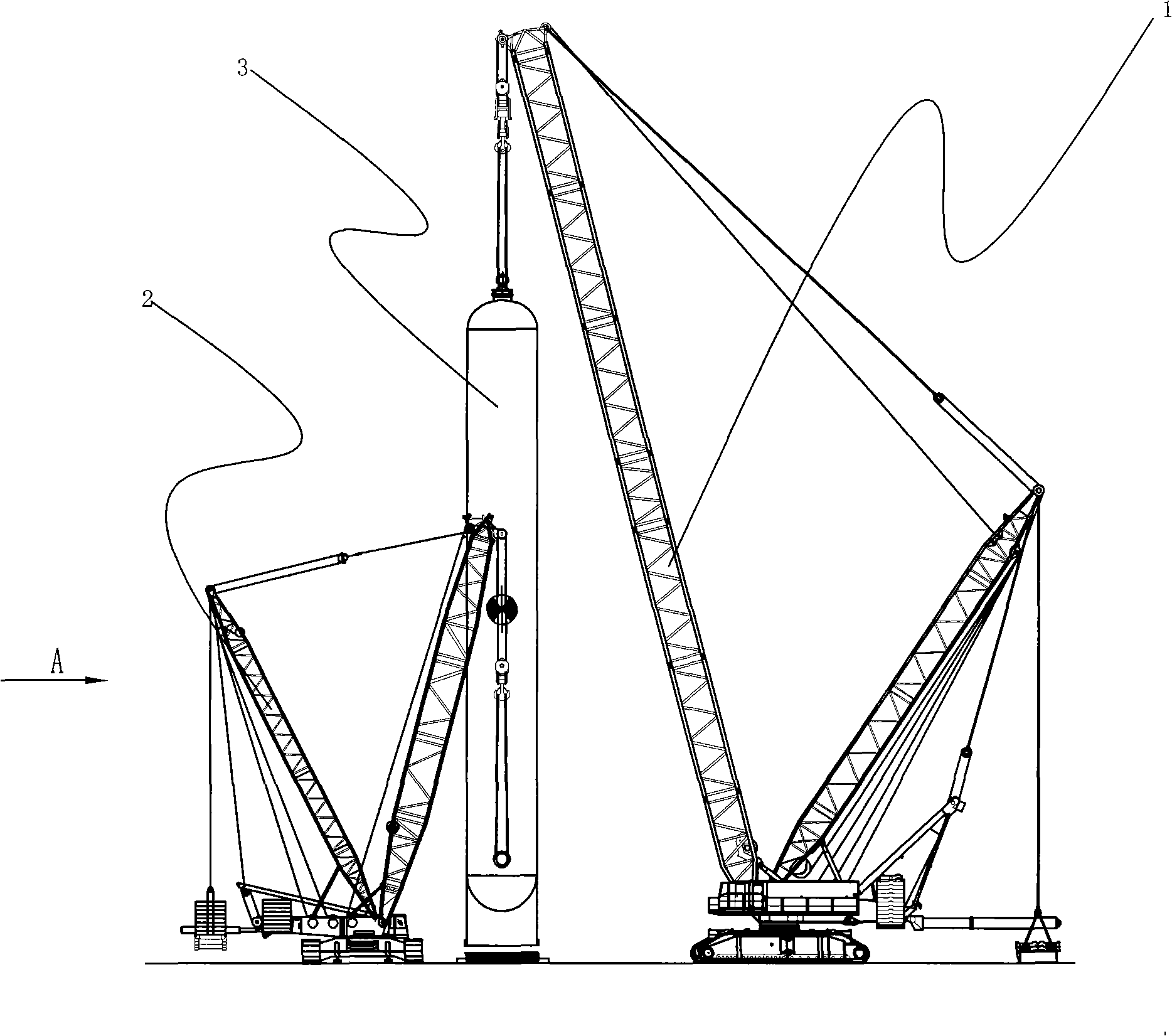

[0022] as 1 to Figure 4 As shown, the hoisted reactor 3 weighs 1600 tons, has a diameter of 6 meters and a length of 56 meters. The main crane 1 is hoisted by a DEMAG CC8800 1250-ton crane. According to the hoisting elevation and hoisting performance table, the rated hoisting weight of the crane is 832 tons. Except for 39 tons of hooks, the hoisting rigging is about 20 tons, and the maximum hoisting weight of a 1250-ton crane is 773 tons; two LR1750-type 750-ton cranes are two LR1750-type cranes. The hoisting capacity is 635 tons, excluding the weight of the hook 16 tons, the weight of the hoisting rigging is 10 tons, and the maximum hoisting weight of each tail crane 2 is 609 tons. In this embodiment, the reactor of the hoisted equipment is undertaken by three cranes from hoisting to putting in place. Therefore in the present embodiment, the maximum hoisting weight of the main crane 1 and the tail crane 2 is:

[0023] 773 tons + 609 tons + 609 tons = 1991 tons

[0024] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com