Developing box, process cartridge and electronic imaging device

A technology for developing cartridges and process cartridges, applied in the field of printing devices, can solve the problems of complex drum cartridge structure, long volume and instability of the split-type process cartridge, and achieve the effects of miniaturization, compact structure and quick installation of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

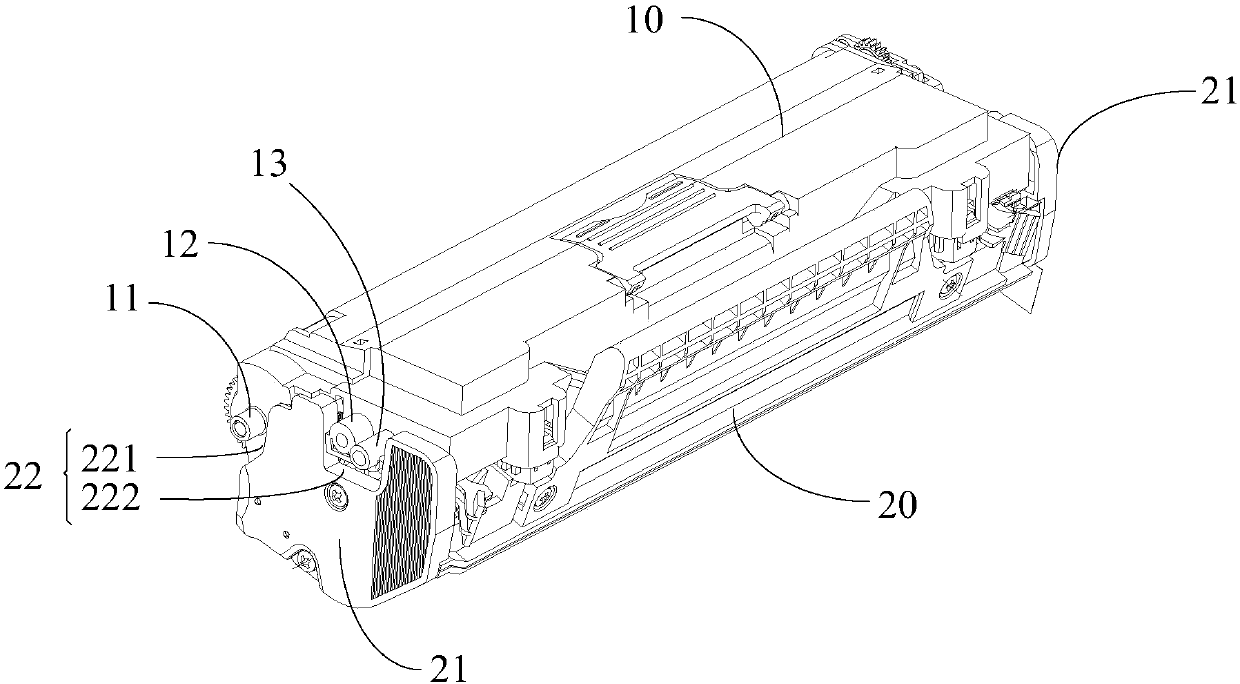

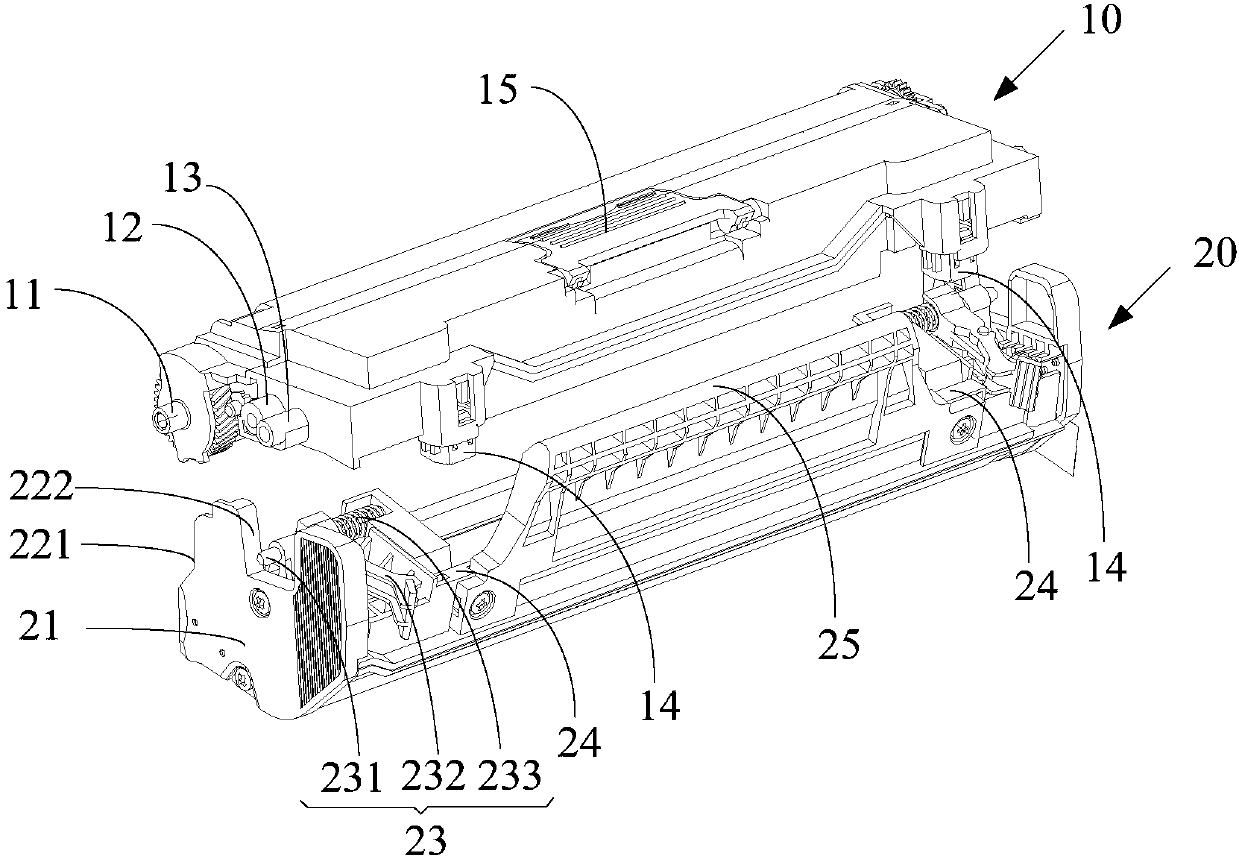

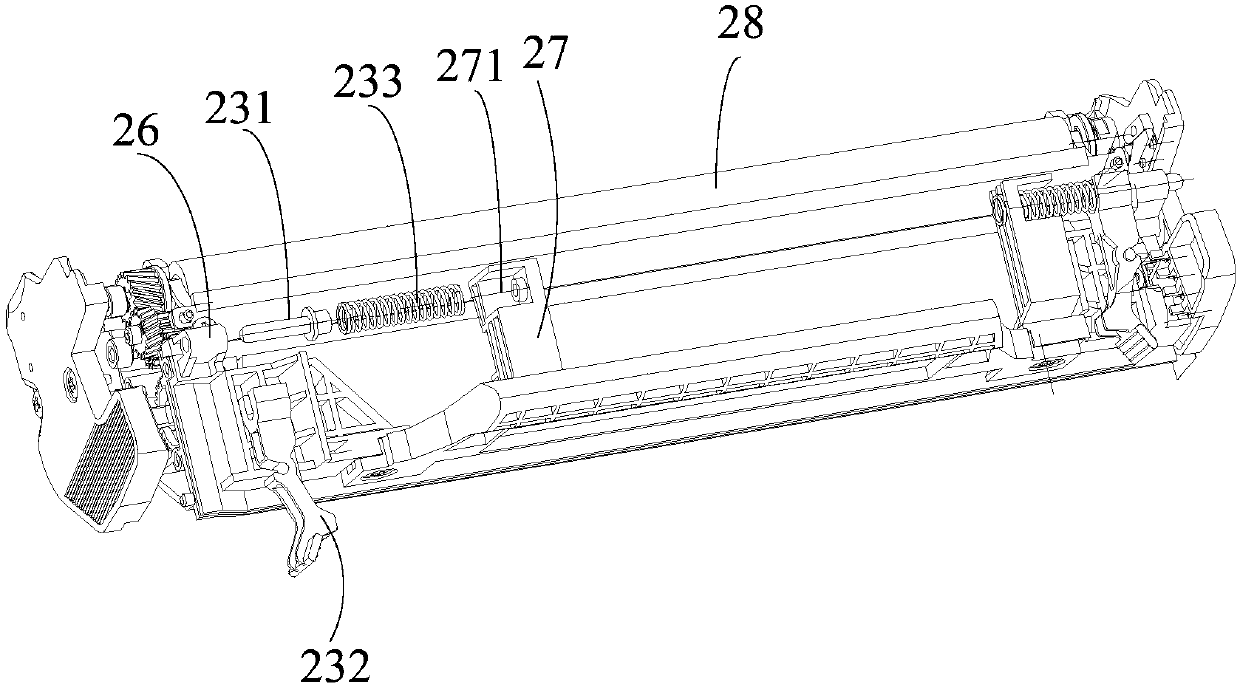

[0052] figure 1 is a schematic structural view of the process cartridge provided in Embodiment 1 of the present invention, figure 2 It is a schematic diagram of the disassembly structure in the process cartridge provided by Embodiment 1 of the present invention, image 3 It is a disassembled schematic diagram of the telescopic assembly on the developing cartridge in the process cartridge provided by Embodiment 1 of the present invention, Figure 4 It is a schematic diagram of the assembly of the telescopic assembly on the developing cartridge in the process cartridge provided by Embodiment 1 of the present invention, Figure 5 It is a structural schematic diagram of the operating member in the telescopic assembly in the process box provided by Embodiment 1 of the present invention, Image 6 It is a structural schematic diagram of the engaging part of the telescopic assembly in the process box provided by Embodiment 1 of the present invention, Figure 7 It is a schematic st...

Embodiment 2

[0078] Wherein, in the existing process cartridge, the developing cartridge slides along the slideway on the drum cartridge for a long distance so that the developing roller 28 and the photosensitive drum 16 can be in place. 10 falls off, and an elastic locking device and a forcing device are often provided at the rear of the drum box 10, which makes the structure of the drum box complicated, and the drum box 10 is subject to more elastic forces, making the structure of the drum box 10 becomes unstable, for this reason, this embodiment provides a kind of processing box, specifically can refer to Figure 1-11 As shown, the process box includes a detachable developer cartridge 20 and a drum cartridge 10, wherein the end of the drum cartridge 10 is provided with a mounting portion 12; Telescopic telescopic assembly 23, telescopic assembly 23 is used for snapping into installation portion 12 when drum cartridge 10 and developing cartridge 20 are installed, so that drum cartridge 1...

Embodiment 3

[0083] This embodiment provides a developing cartridge 20, such as Figure 2-8 As shown, the developer cartridge 20 is detachably connected with the drum cartridge 10, wherein, the end of the developer cartridge 20 is provided with an end cover 21 and a telescopic assembly 23 that stretches towards the end cover 21, and the end of the drum cartridge 10 is provided with a mounting portion 12. The telescopic assembly 23 is used to snap into the installation part 12 when the drum cartridge 10 and the developer cartridge 20 are installed, so that the drum cartridge 10 and the developer cartridge 20 are detachably connected, so that the developer cartridge 20 and the drum cartridge 10 are connected by telescopic The component 23 snaps into the installation part 12 to prevent the developer cartridge 20 from falling off the drum cartridge 10, avoiding the problem that the drum cartridge 10 is provided with an elastic locking device and a forcing device, which causes the drum cartridge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com