Clip

A clip and head technology, applied in the direction of threaded fasteners, thin plate connections, clothing, etc., can solve the problems of installation at a fixed position, clip insertion, fit and disengagement, etc., to achieve rapid and reliable installation, easy installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

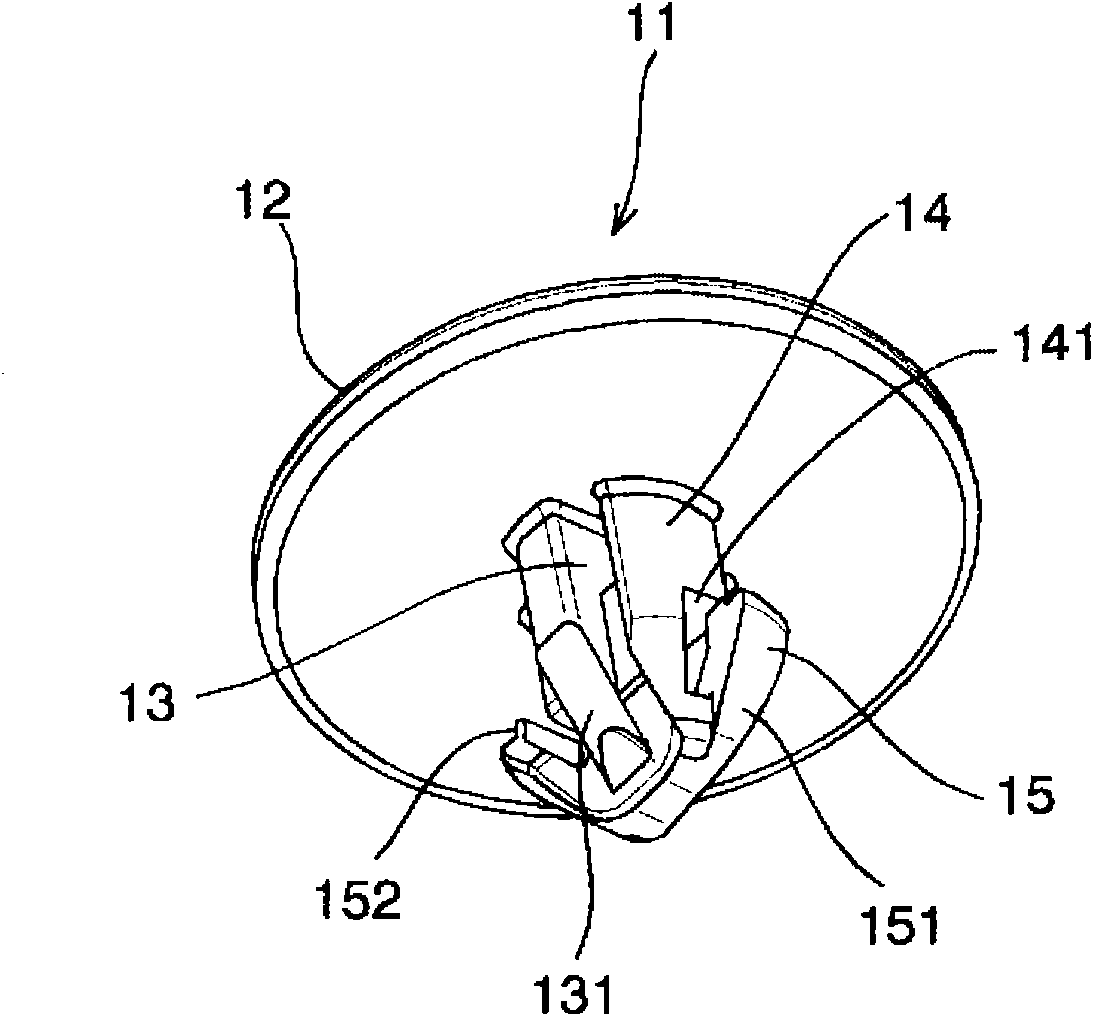

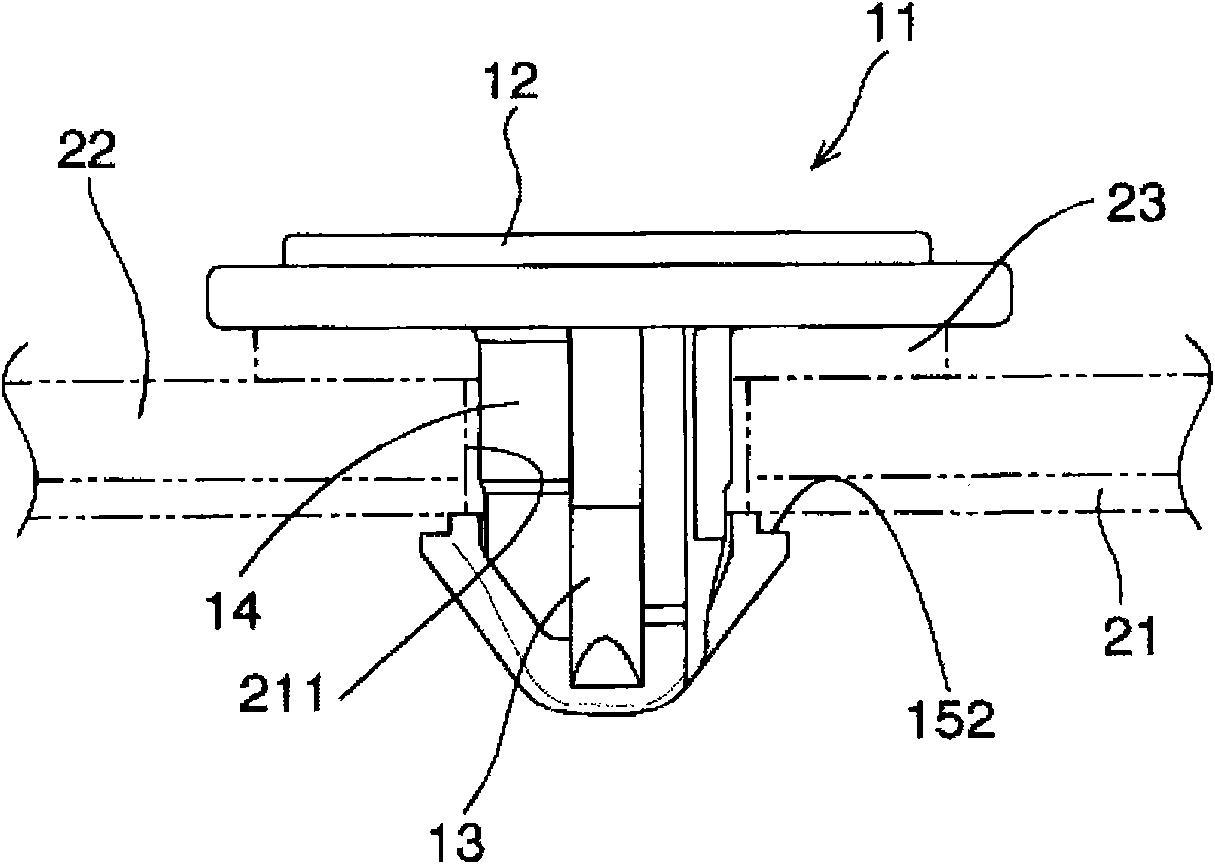

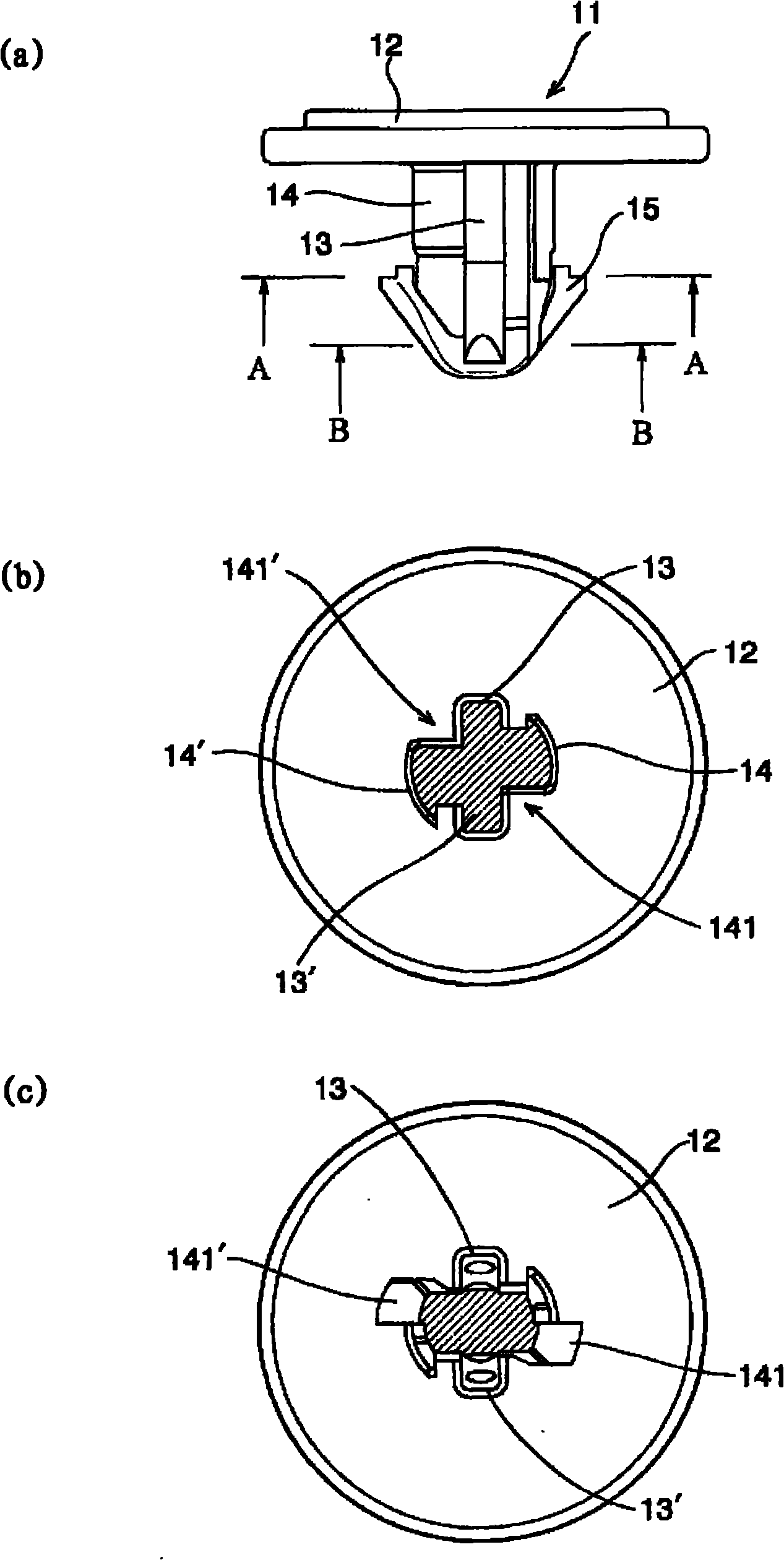

[0032] figure 1 It is a perspective view of the clip of the embodiment of the present invention. figure 2 It is a figure for explaining the state in which the clip which concerns on the embodiment of this invention is attached to the opening provided in the plate-shaped member. exist figure 1 and figure 2 Among them, the clip 11 is installed in the mounting holes 211 provided on the plate-shaped members 21 , 22 to be mounted on the mounted parts such as the fender inner panel and the fender. The clip 11 includes at least a head 12 , a central support 13 , an auxiliary support 14 , a V-shaped elastic leg 15 , a locking portion 152 and a space 141 . The head portion 12 has a shape locked to one surface of the plate-shaped member 21 via, for example, a packing 23 and a plate-shaped member 22 . The center pillar 13 has a shape that integrally protrudes downward from the head 12 and is inserted into the attachment hole 211 .

[0033] Like the central support 13 , the sub-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com