Four-axis direction-adjustable component mounting mechanism

A technology of parts installation and axial direction, which is applied in the field of parts installation mechanism with adjustable four-axis direction, can solve the problems of time-consuming, loose parts, small parts, etc., so as to reduce production costs, improve production efficiency, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

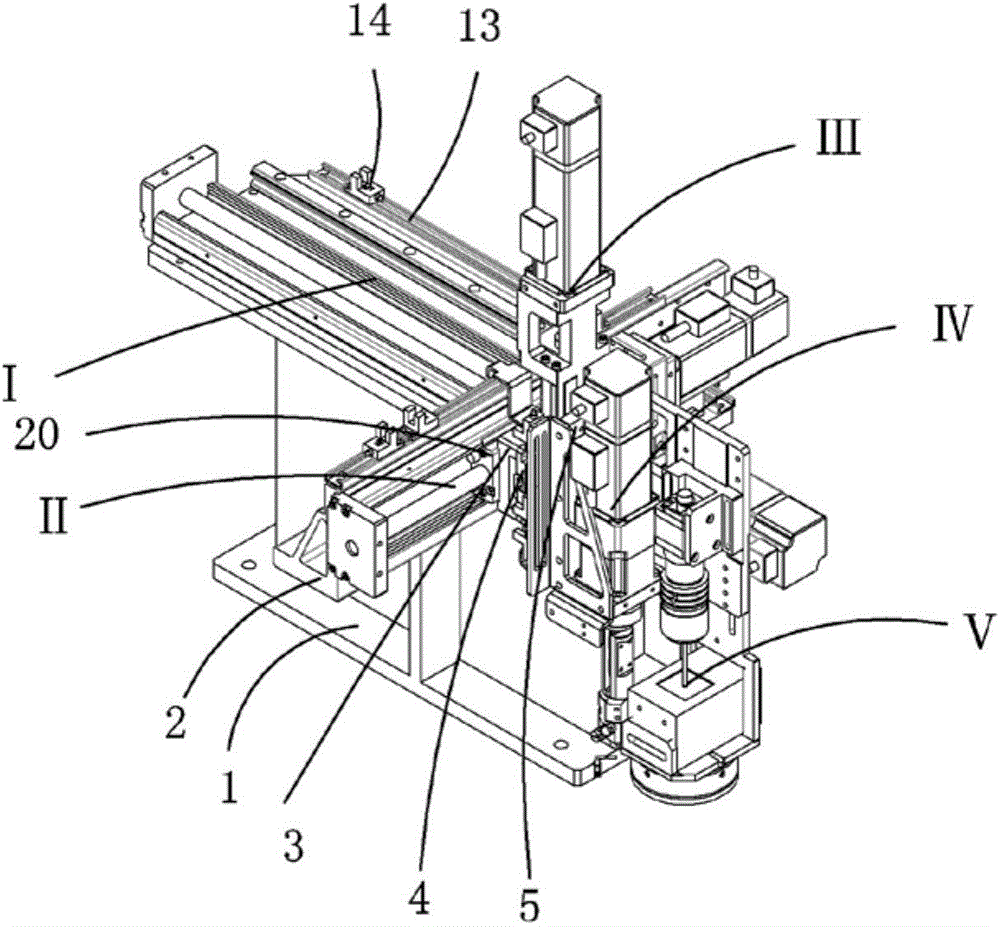

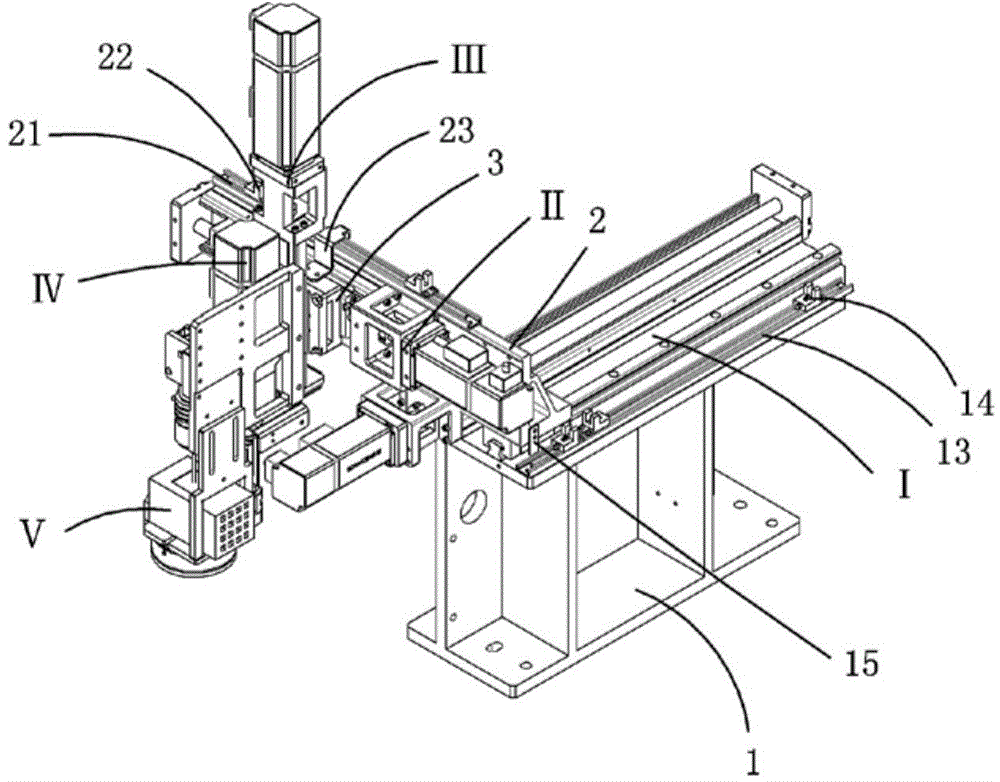

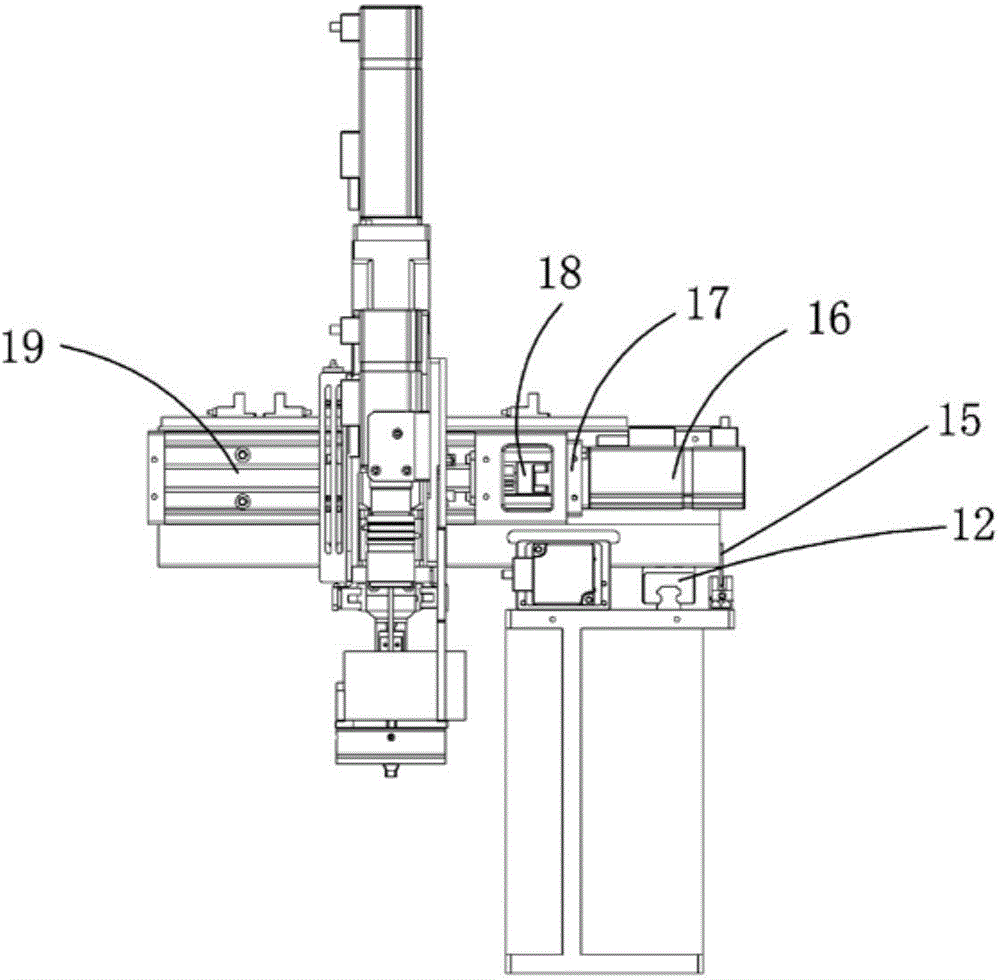

[0030] Examples, see attached Figure 1-11 , a four-axis direction adjustable parts installation mechanism, which includes a base 1, a Y-axis mechanism I, an XY connecting plate 2, an X-axis mechanism II, an XZ connecting block a3, an XZ connecting block b4 and a Z-axis mechanism III, the The Y-axis mechanism is installed on the base, the X-axis mechanism is installed on the Y-axis mechanism through the XY connecting plate, and the Z-axis mechanism is installed on the front of the X-axis mechanism through the XZ connecting block a and the XZ connecting block b, and also includes R Axis mechanism IV and CCD mechanism V, the R-axis mechanism is installed on the front of the Z-axis mechanism through the ZR connecting plate 5, and the CCD mechanism is installed on the right side of the R-axis mechanism.

[0031]The Y-axis mechanism includes a Y-axis motor 6, a Y-axis motor mounting plate 7, a Y-axis coupling 8, a Y-axis linear module 9, a Y-axis linear module slider 10, a Y-axis s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com