Automatic vegetable cultivation and processing method

A processing method and vegetable technology, applied in botany equipment and methods, flower pot filling, gardening, etc., can solve the problems of inconsistent vegetable quality, unsatisfactory productivity, and inability to adapt to a large number of vegetables, and achieve vegetable quality Uniform, high-productivity results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

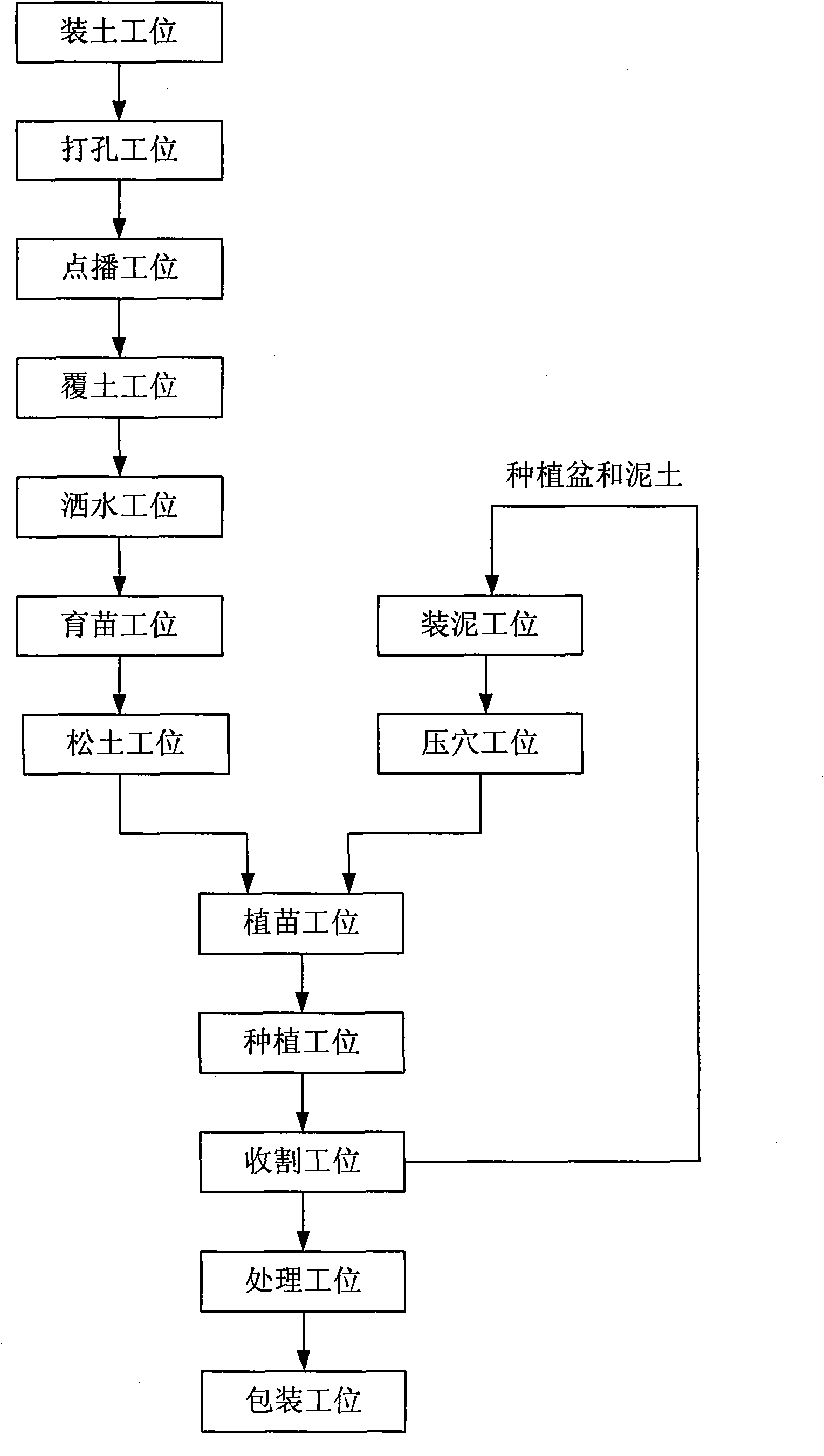

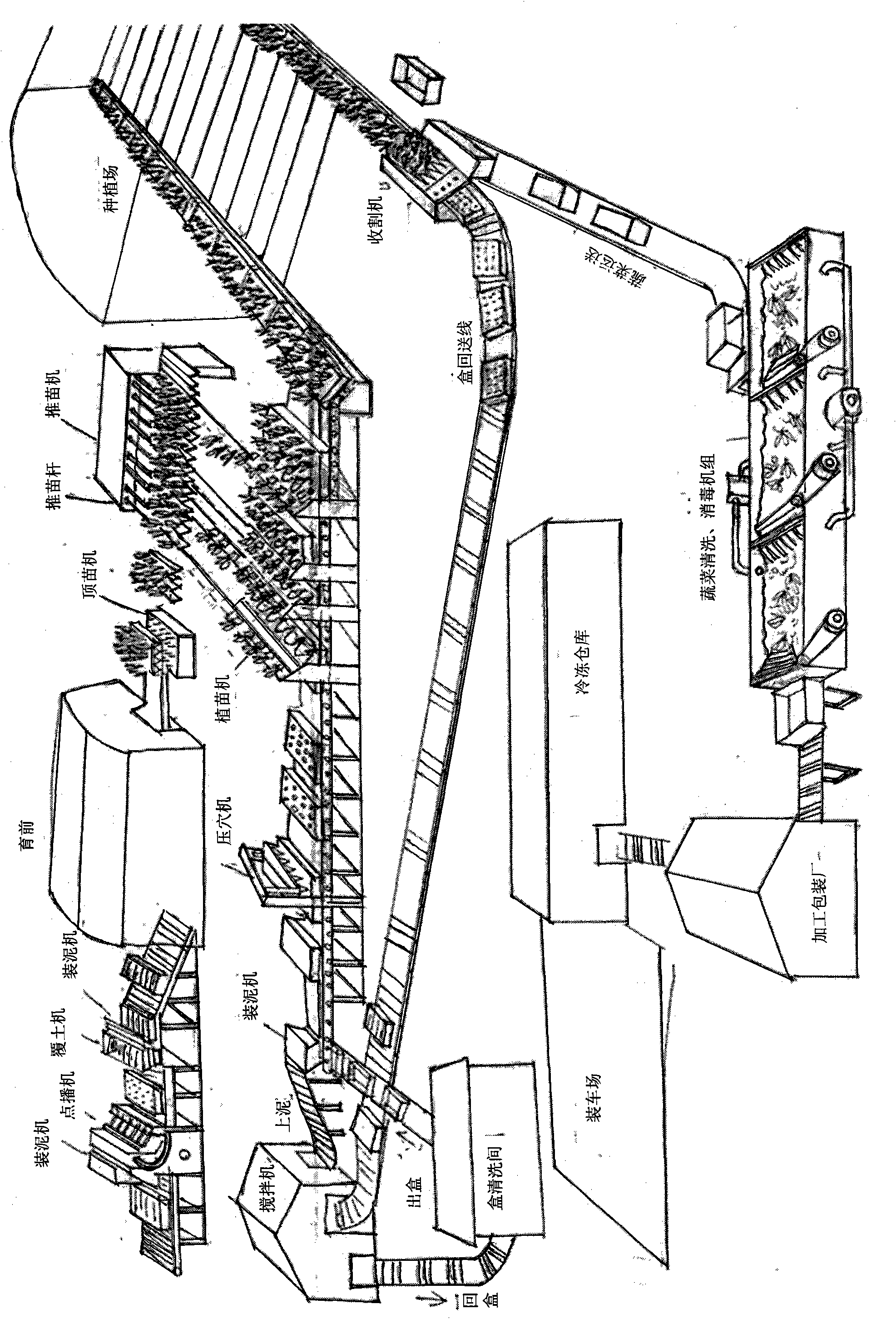

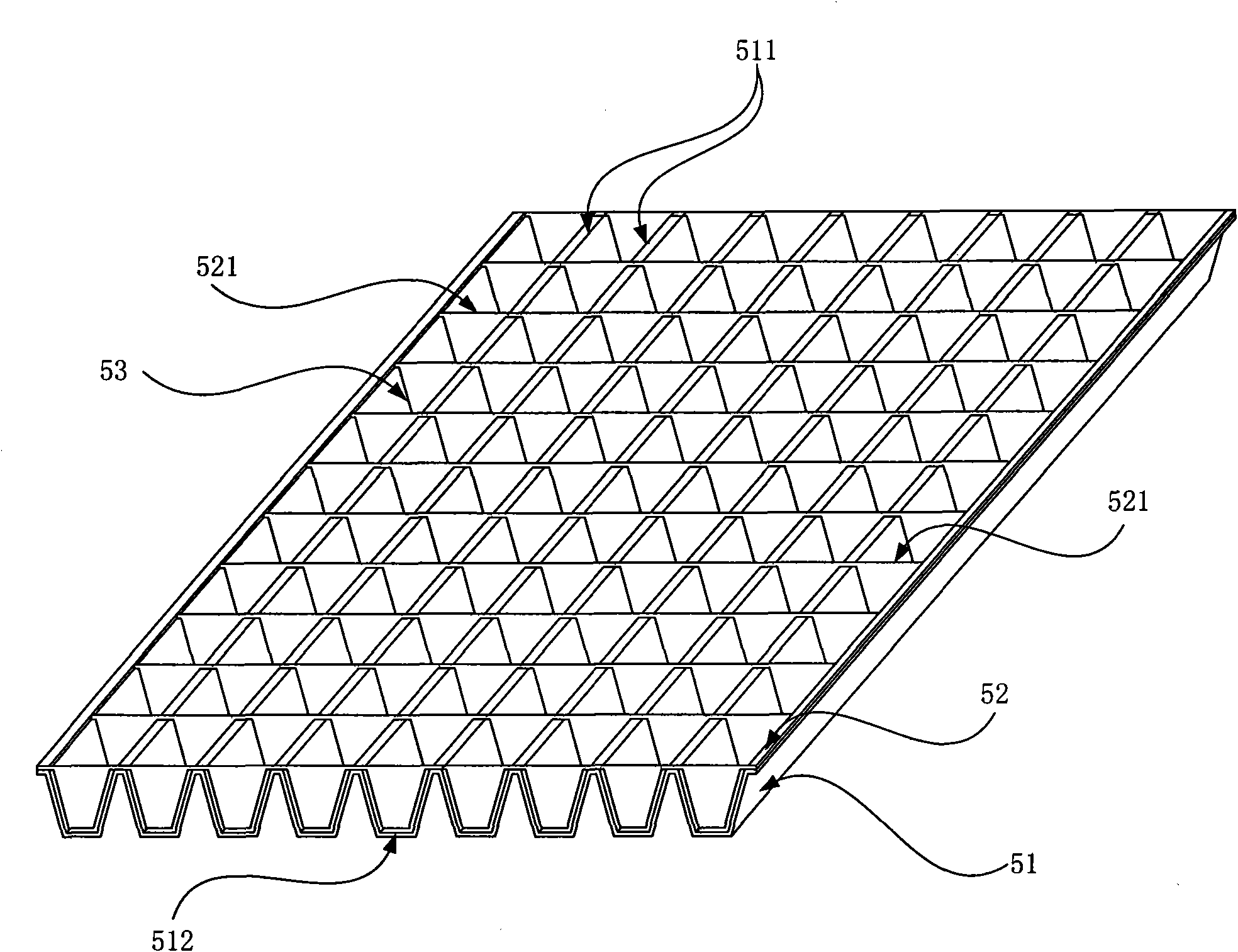

[0030] Such as Figure 1 to Figure 9 As shown, an automatic vegetable planting and processing method, the method includes the following steps: A: the first conveying mechanism carries the seedling tray through the soil loading station, punching station, on-demand station, soil covering station, and watering station in sequence and the seedling raising station; B: after step A, the second conveying mechanism carries the seedling raising tray through the pine seedling station to the seedling planting station, and at the seedling planting station, the seedlings with soil move in an orderly and directional manner; C: the third The conveying mechanism carries the planting pots through the mud loading station, hole pressing station, seedling planting station and planting station in sequence. At the seedling planting station, the planting pots store t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com