Fully-automatic submersible panting type multi-cylinder dish-washing machine

A fully automatic and dishwasher technology, which is applied to tableware washing machines/rinsing machines, cleaning equipment, household utensils, etc., and can solve the problem that it is difficult to achieve all-round and powerful washing of dishes, the washing force is easily blocked, and the The water outlet is easy to block, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

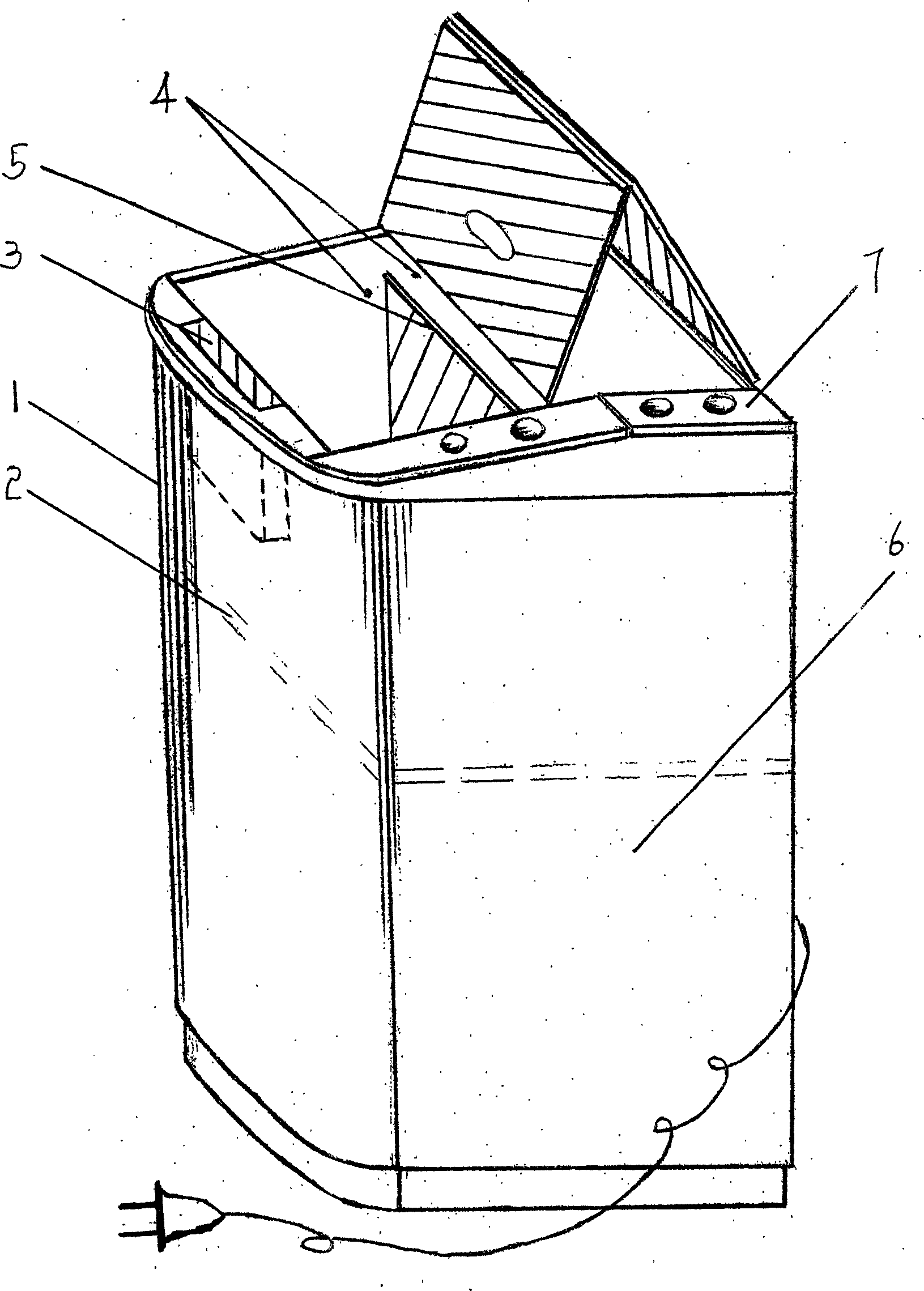

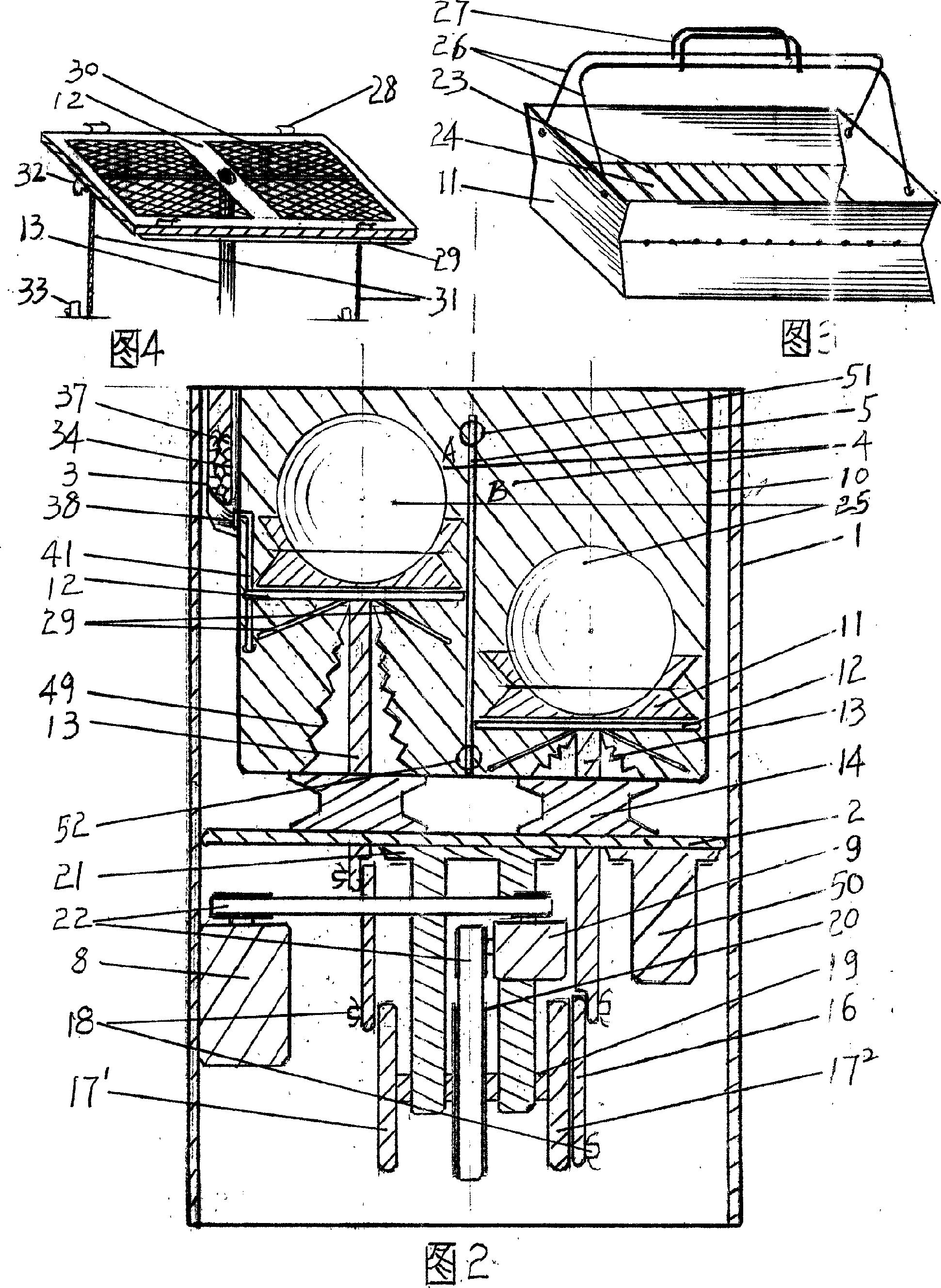

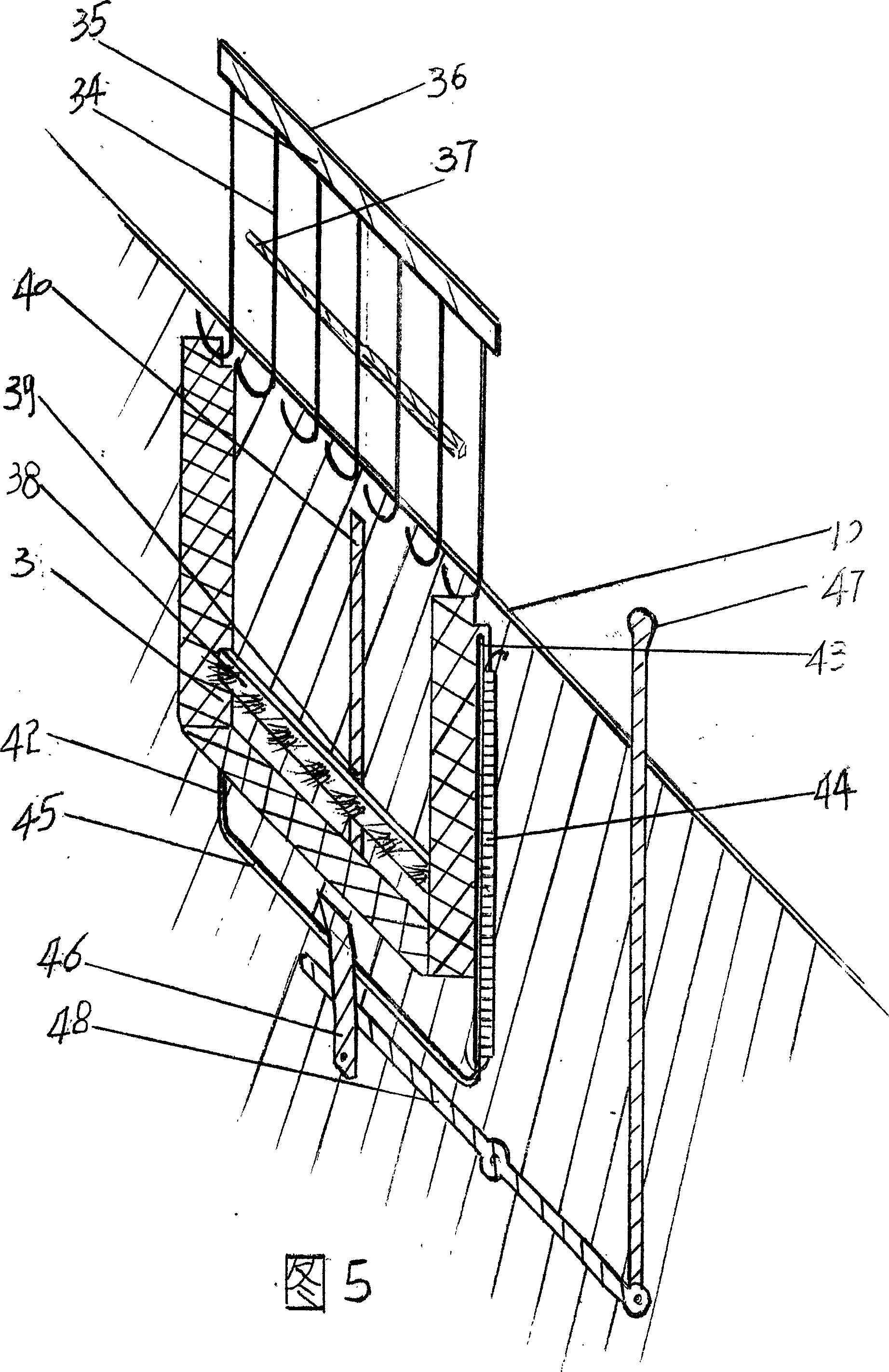

[0014] correspond figure 1As shown in the fully automatic immersion Trent type multi-tank dishwasher, the main components in the body are distributed as shown in the figure. 1 is the body, 2 is the seat plate, 3 is the chopstick box, 4 is the water tank, 5 is the partition, 6 is the motor and Its transmission device, 7 is automatic control device. Referring to Fig. 2, a seat plate (2) connected with the body (1) is arranged in the dishwasher body (1), and it is divided into upper and lower parts, and the lower part is provided with a motor (8), a reducer (9) and its Transmission device, the upper part is provided with a cavity (10) and a chopstick box (3) for containing washing water, and a partition (5) is erected in the cavity (10) to divide it into two water tanks (4) or more Mouth water tank, with A, B two water tanks (4), each water tank (4) is respectively provided with the movable frame (12) (shown in Figure 4) of supporting bowl blue (11) (Japanese font), The movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com