Automatic testing method for concentricity quality of piezoelectric ceramic silver plate and device

A piezoelectric ceramics, automatic detection technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of unable to find the circle, the algorithm of the inner circle and the outer circle are coincident together, and the inner circle cannot be detected. The effect of improving the degree of automatic detection, high recognition accuracy and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

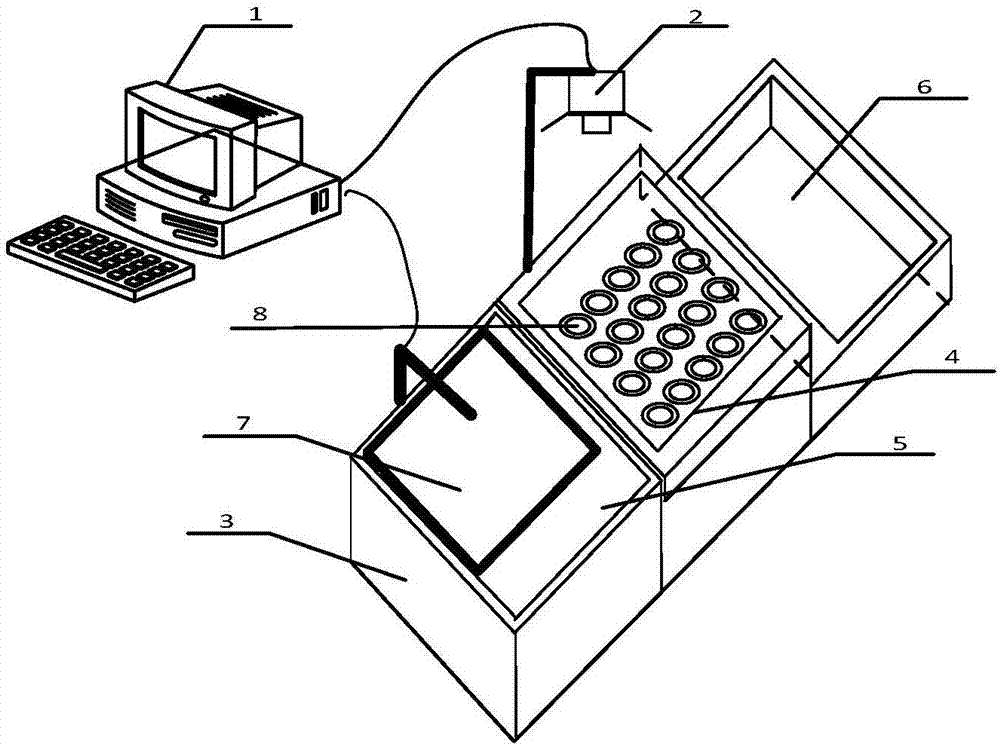

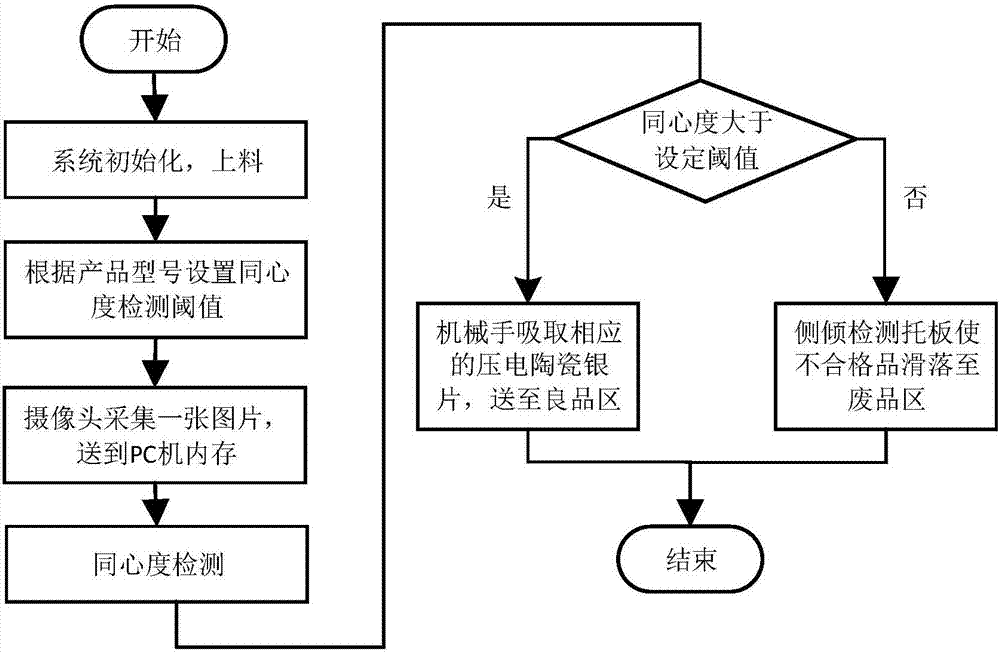

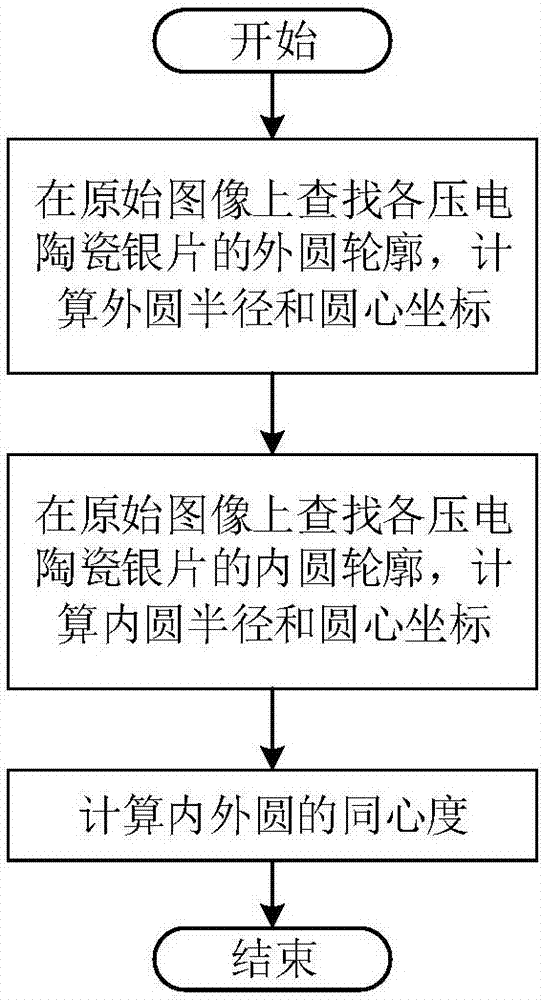

[0049] Such as figure 1 As shown, an automatic detection device for the concentricity quality of piezoelectric ceramic silver sheets in this embodiment includes a PC 1, a camera 2, a workbench 3, a detection pallet 4, a good product area 5, a reject frame 6, and a manipulator 7. The camera 2 is set above the detection pallet 4, and the specific height can be set according to the parameters of the camera, the size of the piezoelectric ceramic silver piece to be detected and other factors, for example, it can be set to 30-50cm. The PC 1 is connected to the camera 2 and the manipulator 7 in a wired or wireless manner, and is used to receive the image taken by the camera 2. Based on the image processing method, the quality inspection of the concentricity of the piezoelectric ceramic silver plate in the current image is performed according to The quality inspection result determines the position of the good product, and then sends a signal to the manipulator 2, and the manipulator 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com