Automatic labelling equipment for hub, and production line

A technology for sticking labels and hubs, which is applied in the field of hub packaging, can solve problems such as wrong label pasting position, wrong label model, wrong label printing, etc., and achieve the effect of preventing pasting mistakes, preventing complaints, and preventing confusion and mistakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

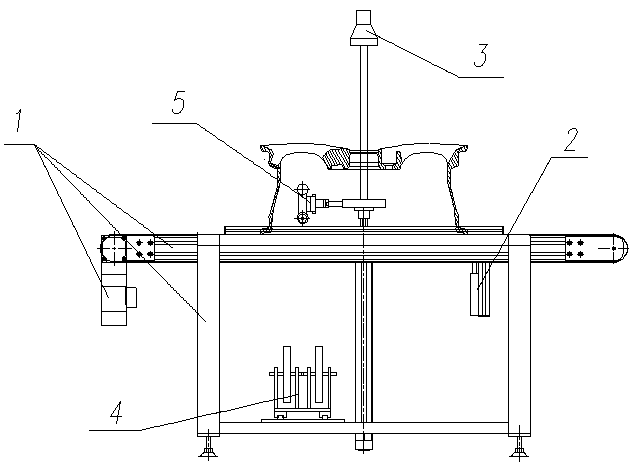

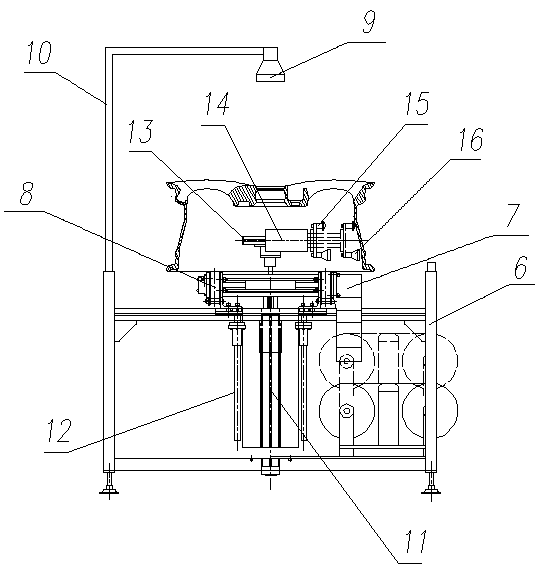

[0028] The following is attached with the manual Figure 1-2 An automatic hub labeling device according to Embodiment 1 of the present application is described, including a transmission mechanism 1 , a blocking component 2 , a camera recognition module 3 , a label printer 4 , and a label sticking mechanism 5 .

[0029] The transmission mechanism 1 is used to transmit the hub. The transmission mechanism 1 includes a frame 6, a motor 7, and a conveyor belt 8. A conveyor belt 8 is arranged on the frame 6. The motor 7 is fixed on one end of the conveyor belt 8. The motor 7 drives the conveyor belt 8 to rotate. The blocking part 2 can block the hub, so that the hub stops on the transmission mechanism 1 , and releases the hub, so that the hub continues to be transmitted on the transmission mechanism 1 . The frame 6 of the transmission mechanism 1 is also provided with a first hub detection element adjacent to the position of the blocking part 2. The first hub detection element can d...

Embodiment 2

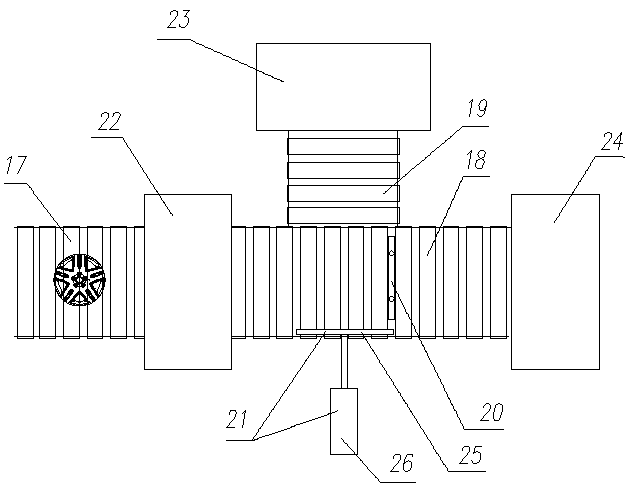

[0035] The following is attached with the manual image 3 Description of Embodiment 2 of the present application A production line for sorting and labeling, including a first roller table 17, a second roller table 18, a third roller table 19, a second blocking component 20, a sorting component 21, and a second camera recognition module 22 , is characterized in that it also includes two hub automatic labeling equipment described in any one of the above-mentioned embodiments, which are hub automatic labeling equipment one 23 and hub automatic labeling equipment two 24, the first roller table 17 and the second roller The roads 18 are connected in a straight line, and the third roller table 19 is perpendicular to the second roller table 18. The hub automatic labeling device one 23 is arranged on the third roller table 19, and the hub automatic labeling device two 24 is arranged on the second roller table 19. On the roller table 18; the second camera recognition module 22 is set on...

Embodiment 3

[0041] Such as Figure 4 As shown in , a continuous labeling production line disclosed in the present application includes the fourth roller table 27, the fifth roller table 28, and the sixth roller table 29, and also includes two wheel hubs described in any of the above-mentioned embodiments. The automatic labeling equipment is the wheel hub automatic labeling equipment three 30 and the wheel hub automatic labeling equipment four 31 respectively, the fourth roller table 27 is connected to the wheel hub automatic labeling equipment three 30, and the wheels are transferred to the wheel hub automatic labeling equipment three 30, and the fifth roller table 28 Connect the wheel hub automatic labeling equipment three 30 and the wheel hub automatic labeling equipment four 31, the sixth roller table 29 is connected to the output end of the hub automatic labeling equipment four, and transport the wheel hub after labeling; the wheel hub automatic labeling equipment three 30 and The lab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com