Automatic screen stirring device

A stirring device and screen technology, applied in the field of enamel, can solve the problems of high cost of enamel powder, uneven mixing, high labor intensity, etc., and achieve the effect of improving the first pass rate, reducing labor intensity, and improving uniformity and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

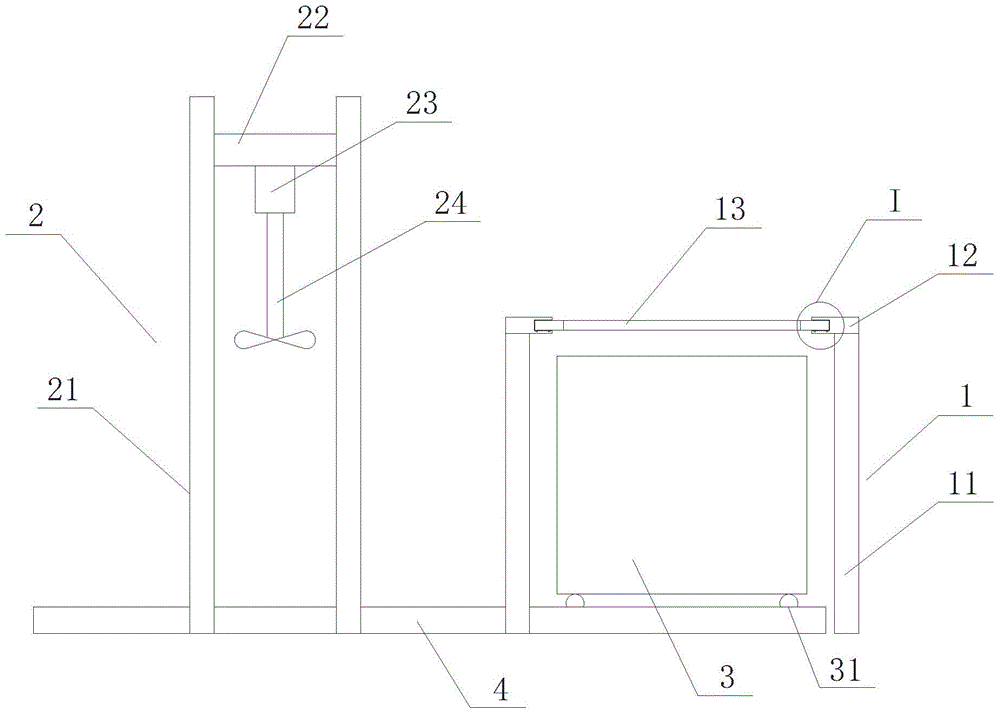

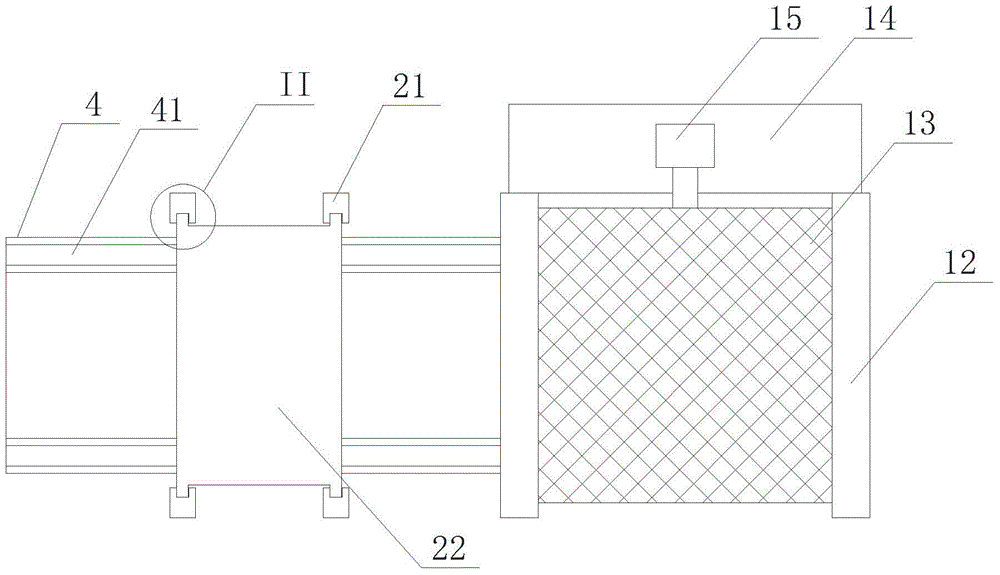

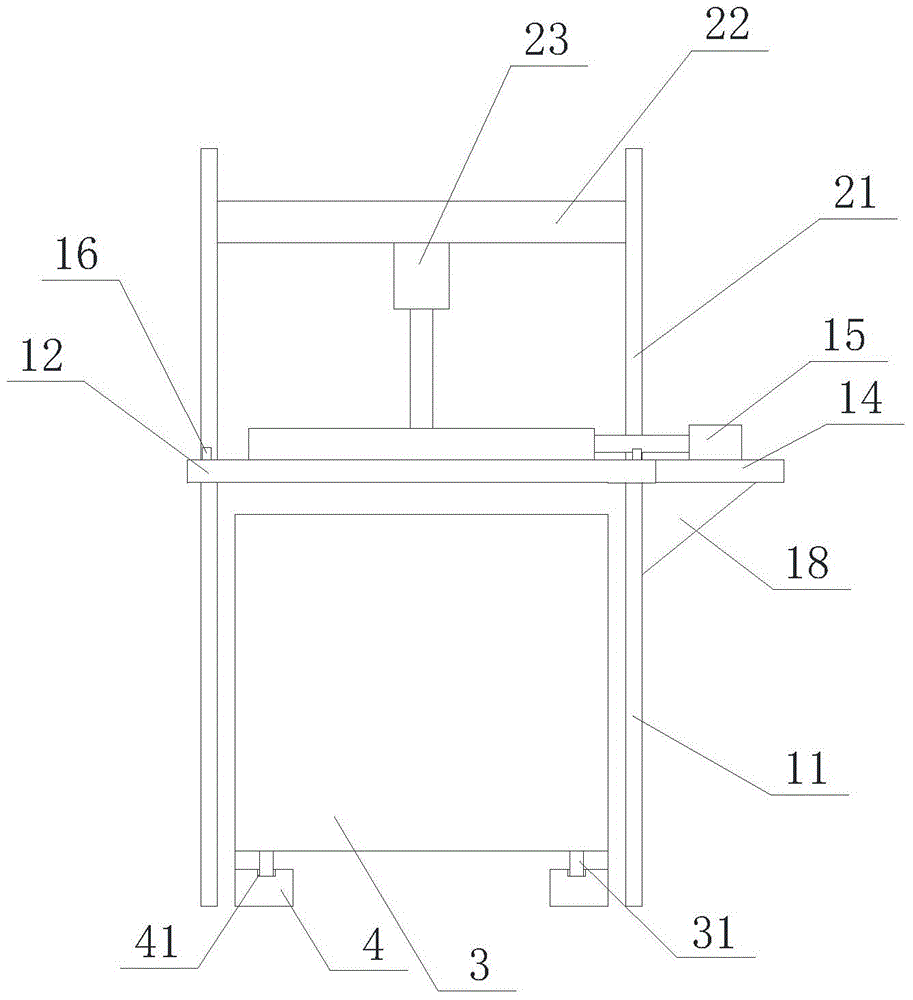

[0024] The present invention as Figure 1-6 As shown, it includes a screen device 1, a stirring device 2, a storage box 3 and a pair of slide rails 4, the screen device 1 and the stirring device 2 are placed side by side, and the pair of slide rails 4 are located in the screen device 1 and below the stirring device 2, the storage box 3 is movably arranged on the pair of slide rails 4;

[0025] The pair of slide rails 4 are respectively provided with slide grooves 41;

[0026] Both sides of the bottom of the material holding box 3 are respectively provided with rollers 31 matched with the chute 41 .

[0027] The screen device 1 comprises a screen support 11, a cylinder 15, a screen 13, a cylinder fixing plate 14 and a pair of screen holders 12 arranged in parallel, and the pair of screen holders 12 are located on the screen On the bracket 11, the opposite faces of the pair of screen fixing frames 12 are respectively provided with suction slots 121 adapted to the screen 13, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com