Zero discharge cooking fume purifier

A technology of oil fume purification and purification device, which is applied in the directions of combination device, oil fume removal, chemical instruments and methods, etc., can solve the problems of clogging of oil fume pipes, inability of filter screen to withstand high temperature, oil pollution and other problems, so as to achieve not easy clogging and effectively kill bacteria. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

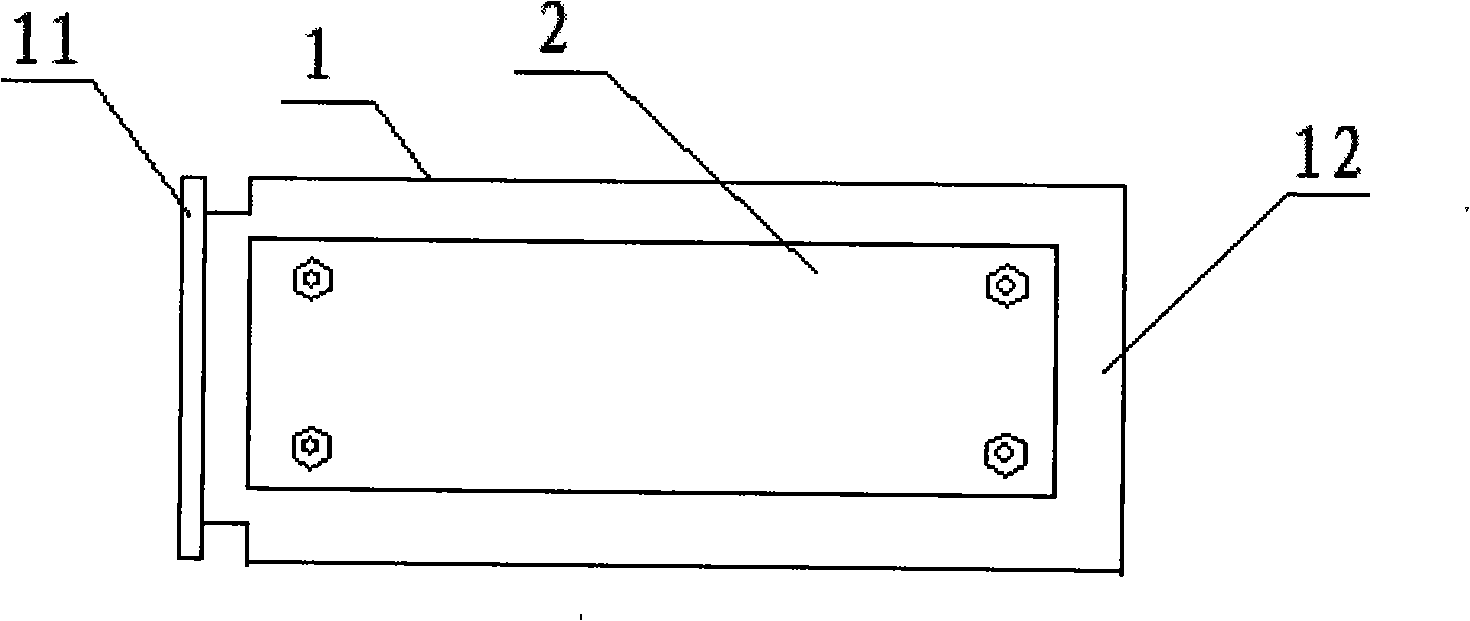

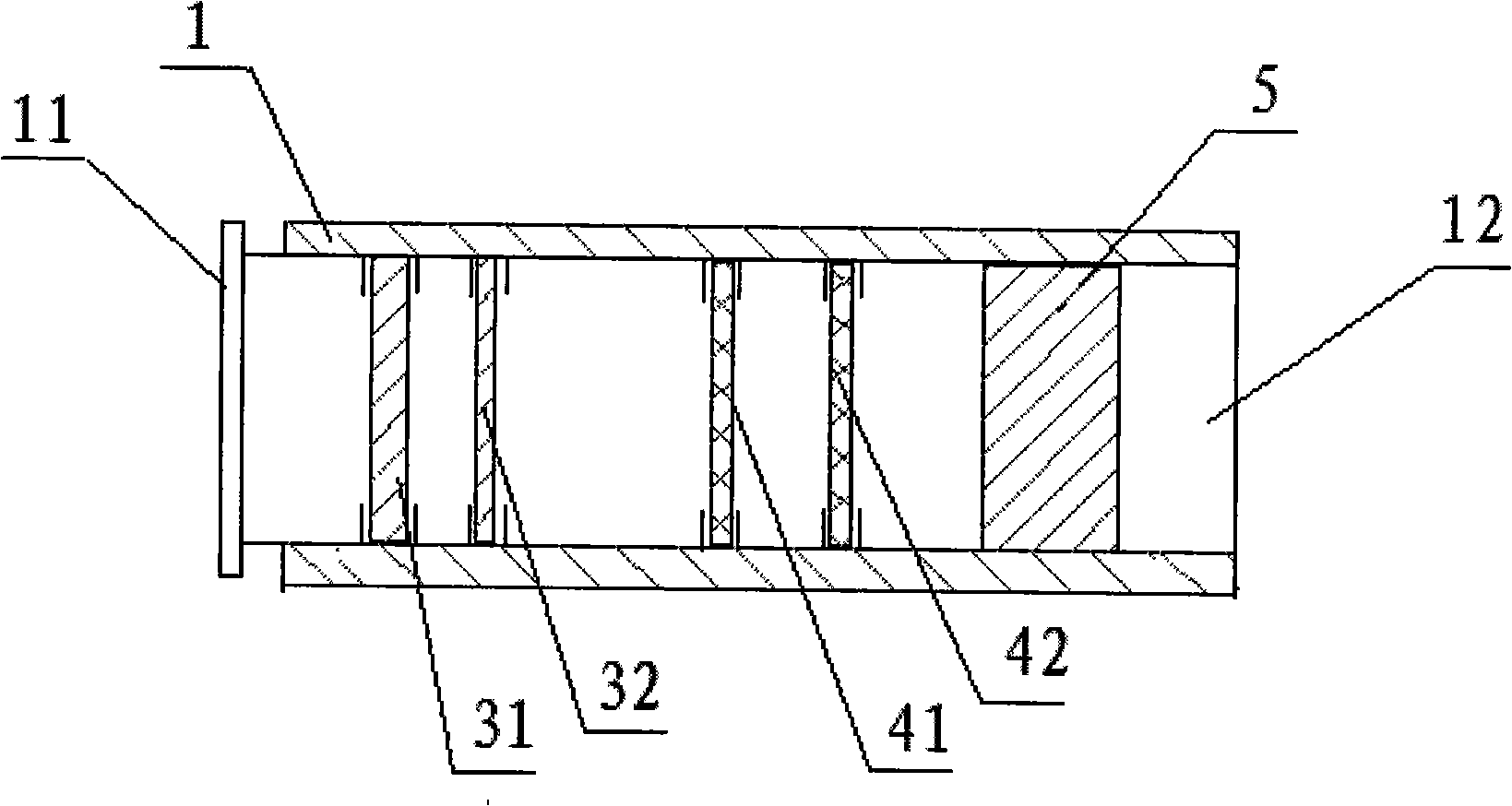

[0035] refer to figure 1 , The zero-emission oil fume purification device has a tubular purification device carrier 1, and the two ends of the purification device carrier 1 are respectively provided with an air inlet 11 and an exhaust port 12. An opening is provided on the side of the carrier wall of the purification device, and the opening is sealed with a detachable baffle plate 2 .

[0036] refer to figure 2 From the air inlet 11 one end of the purification device carrier 1 to the exhaust port 12 one end, the positive electrode 41 of the filter plate 31, the filter plate 32, the dust removal electrode, the negative electrode 42 of the dust removal electrode and the ultraviolet air purification device 5 are housed successively.

[0037] The ultraviolet air purification device 5 can be an ultraviolet air purification device that simply utilizes ultraviolet rays to sterilize. This device has a simple structure, the most reliable performance, and the smallest volume, but its ...

Embodiment 2

[0048] Compared with Embodiment 1, the filter plate part can also be designed as follows.

[0049] refer to Figure 4 , The zero-emission oil fume purification device has a tubular purification device carrier 21, and the two ends of the purification device carrier 21 are respectively provided with an air inlet 211 and an exhaust port 212. An opening is provided on the side of the carrier wall of the purification device, and the opening is sealed with a detachable baffle plate 22 .

[0050] refer to Figure 5 , from the front end of the air inlet 211 of the purification device carrier 21, there is also a smoke cover 26, and one end of the smoke cover 26 is to one end of the exhaust port 212, and the filter plate 231, the positive electrode 241 of the dust removal electrode, and the negative electrode 242 of the dust removal electrode are successively installed And ultraviolet air cleaning device 25.

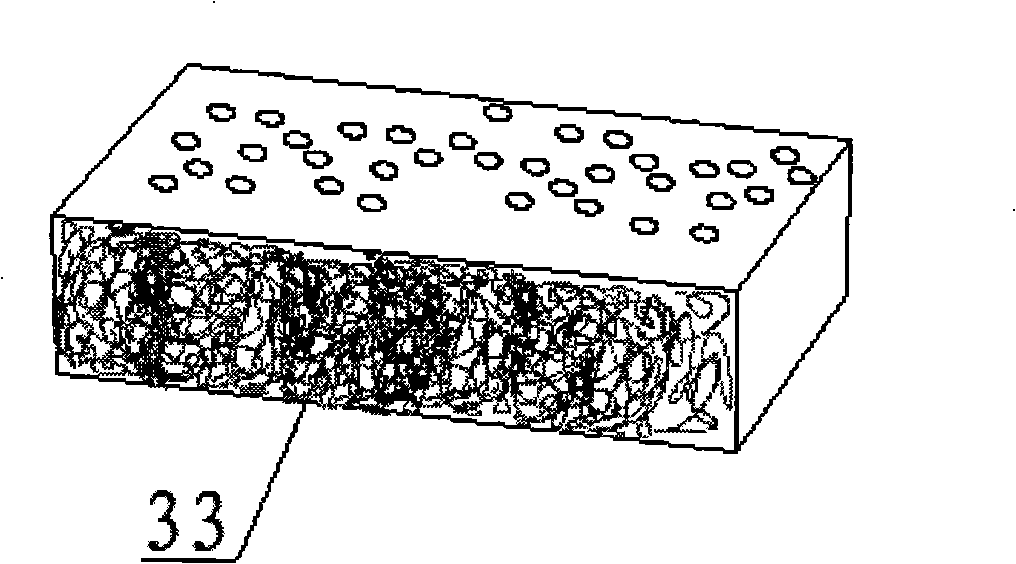

[0051] see Figure 6 , the filter plate 231 includes two stainless steel or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com