Device for preventing coal from burning spontaneously and rapidly extinguishing under coal mine and working method thereof

A coal spontaneous combustion and fire extinguishing device technology, applied in chemical instruments and methods, mixing methods, fire prevention, etc., can solve the problems of low foaming ratio, complicated manufacturing process, blockage, etc., and achieves easy plugging, compact structure, Use reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

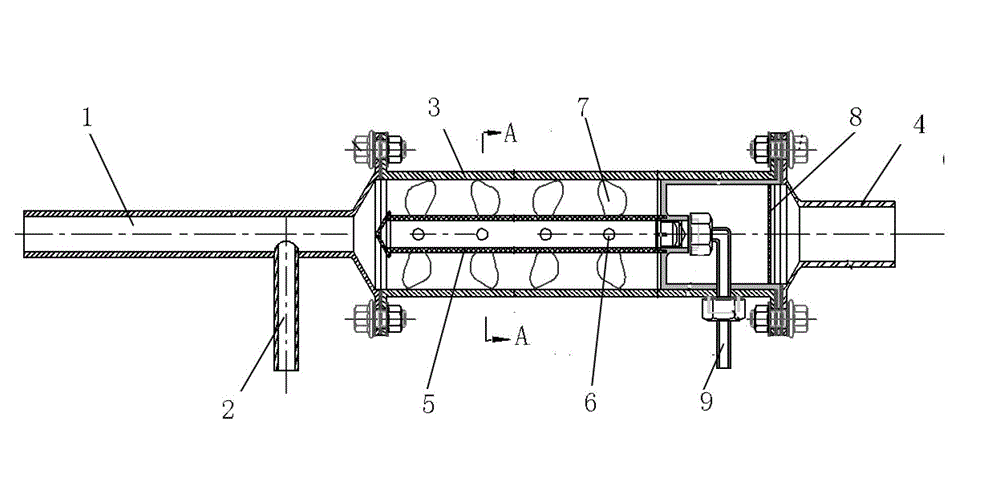

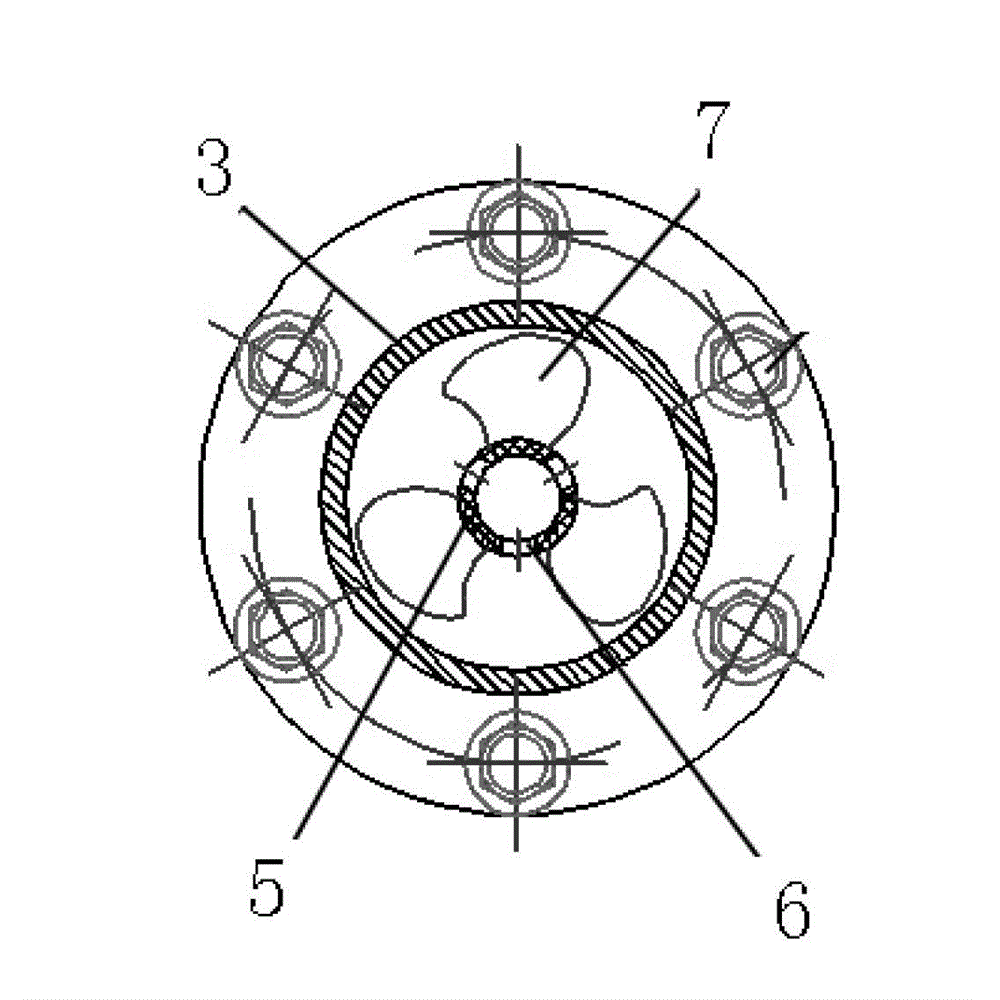

[0022] like figure 1 and figure 2 Shown, a kind of coal mine fire-preventing gel foam generating device, it comprises a cylindrical foam shell 3 that both ends shrink; There is a foam stock solution inlet 2, and the diameter of the compressed air pipe 1 is greater than the diameter of the foam stock solution inlet 2; the other end of the foam shell 3 is connected to a foam output pipe 4; the axis inside the foam shell 3 is provided with a hollow shaft 5, and Six sets of helical blades 7 are arranged at intervals on the shaft 5 , and the distance between them is the distance from the outer surface of the hollow shaft 5 to the inner surface of the foam shell 3 . Air outlet holes 6 are provided between the helical blades 7. In Embodiment 1, the rotation direction of the helical blades 7 and the axial angle of the hollow shaft 5 are 45 degrees. The rotation direction of each group of helical blades 7 is the same. The direction of rotation of the blades 7 is opposite; an auxilia...

Embodiment 2

[0026] The second embodiment is basically the same as the first embodiment, except that the included angle between the direction of rotation of the helical blade 7 and the axial direction of the hollow shaft 5 is 60 degrees. When in use, adjust the auxiliary compressed air pipeline 9 so that the flow ratio of the compressed gas entering the foaming shell 3 and the gel foam stock solution is 25:1, and 80 times the gel foam is formed after foaming.

Embodiment 3

[0028] Embodiment 3 is basically the same as Embodiment 2, except that eight sets of helical blades 7 are arranged at intervals on the hollow shaft 5, and the mesh diameter of the foam net is 2mm. When in use, adjust the auxiliary compressed air pipeline 9 so that the flow ratio of the compressed gas entering the foaming shell 3 and the gel foam stock solution is 30:1, and 120 times the gel foam is formed after foaming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com