Synchronous grouting method for recycling large-diameter waste slurry generated during slurry shield

A waste mud and mud-water shield technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as poor flow in pipes, bulging and cracking of pipes, small amount of cement added, etc., and achieve good flow Effects of water retention and pumpability, reduced water consumption, and improved water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

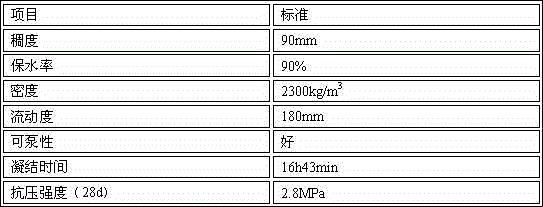

[0017] Preparation of each cubic meter product includes the following weight raw materials: cement 180kg, slaked lime 50kg, fly ash 265kg, sand 1300kg, waste mud 500kg, methyl cellulose 1kg, lignosulfonate 2kg, wood sodium 1.5kg, rosin thermal polymerization Object 0.5kg. The mud indexes of this embodiment are shown in Table 1.

[0018] Table 1

[0019]

[0020] This embodiment also has the following advantages: excellent wetting, uniform dispersion, good water retention effect, improved concrete workability, small slump, strong permeability resistance, high strength and compactness; large amount of air bubbles but small volume of individual air bubbles , so frost resistance and impermeability are strong.

Embodiment 2

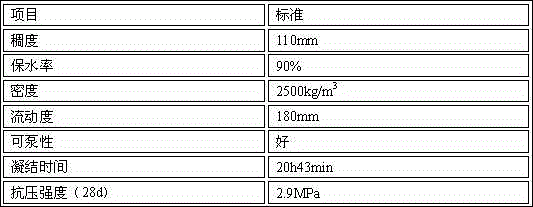

[0022] Preparation of each cubic meter product includes the following weight raw materials: 100kg of cement, 95kg of slaked lime, 180kg of fly ash, 1500kg of sand, 570kg of waste mud, 0.5kg of hydroxypropyl methylcellulose, 1kg of casein, 2kg of sodium citrate, and alkylsulfonate Salt 1.5kg. The mud indexes of this embodiment are shown in Table 2.

[0023] Table 2

[0024] project standard consistency 120mm Water retention 85% density 2450kg / m 3 Liquidity 200mm pumpability it is good clotting time 28h25min Compressive strength (28d) 3.3MPa

[0025] This embodiment also has the following advantages: good water retention, uniform dispersion, good retarding effect, high pumpability, high hardness and high strength after coagulation, long coagulation time, tensile resistance, compression resistance and frost resistance; the introduction of air bubbles, but Strength is not affected.

Embodiment 3

[0027] Preparation of each cubic meter product includes the following weight raw materials: cement 160kg, slaked lime 70kg, fly ash 285kg, sand 1350kg, waste mud 530kg, mortar thickening powder 1.5kg, powder polycarboxylate 0.5kg, sodium pyrophosphate 1kg, fat Sodium alcohol sulfate 2kg. The mud indexes of this embodiment are shown in Table 3.

[0028] table 3

[0029] project standard consistency 130mm Water retention 85% density 2400kg / m 3 Liquidity 200mm pumpability it is good clotting time 22h58min Compressive strength (28d) 3.0MPa

[0030] This embodiment also has the following advantages: safe, non-toxic, non-radioactive and non-corrosive, good water resistance, high durability and bond strength, reduced water volume, high strength after condensation; abundant foam introduced during mixing, stable and long-lasting, non-toxic precipitation phenomenon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com