Wheat flour processing technology for starch alcohol industry and production device

A processing technology, wheat flour technology, applied in the field of food processing, can solve problems such as the difficulty of separating B starch and pentosan, affecting the separation of starch and gluten powder, increasing the cost of starch and alcohol, and achieving the reduction of equipment and plant investment, The effect of moderate ash content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

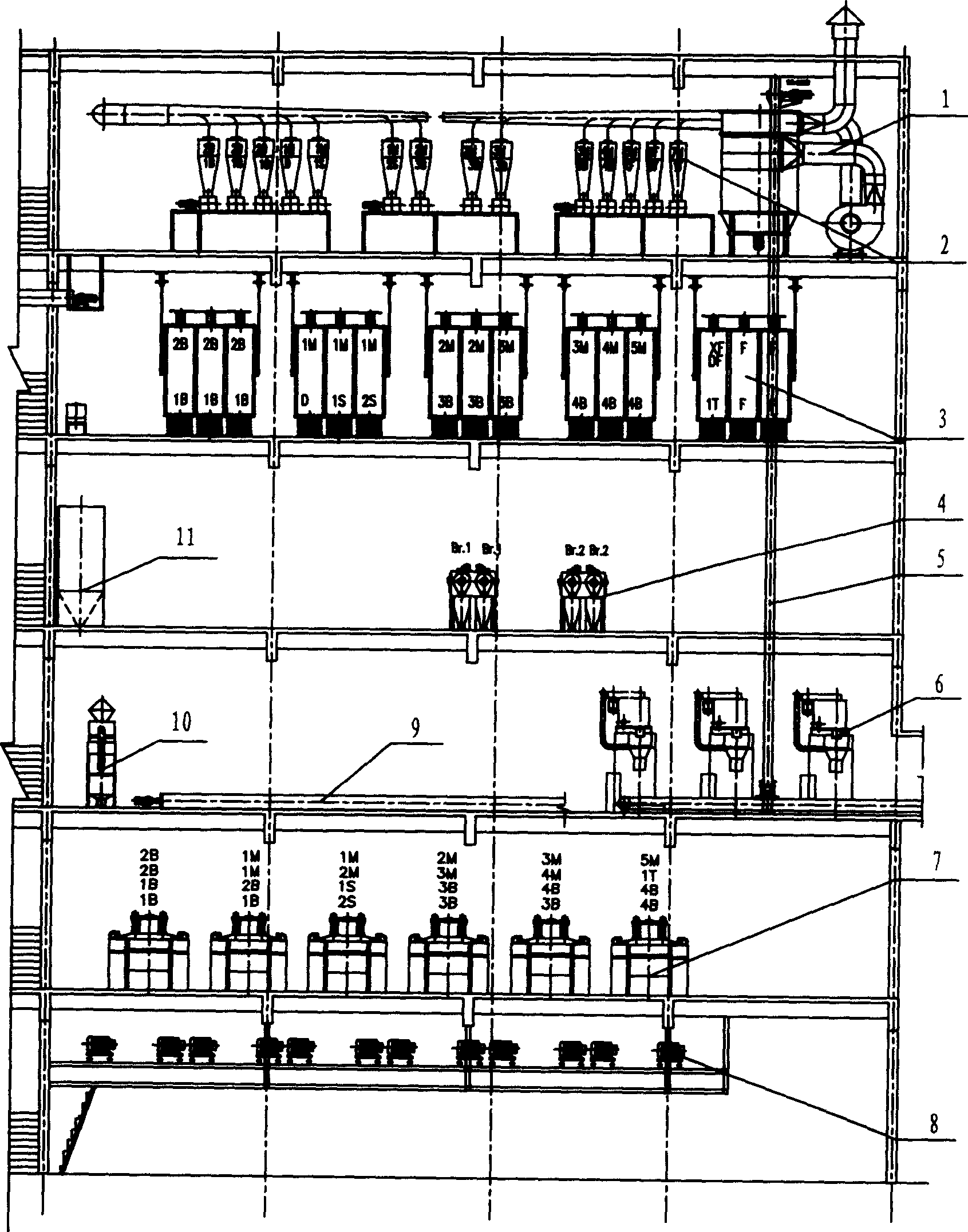

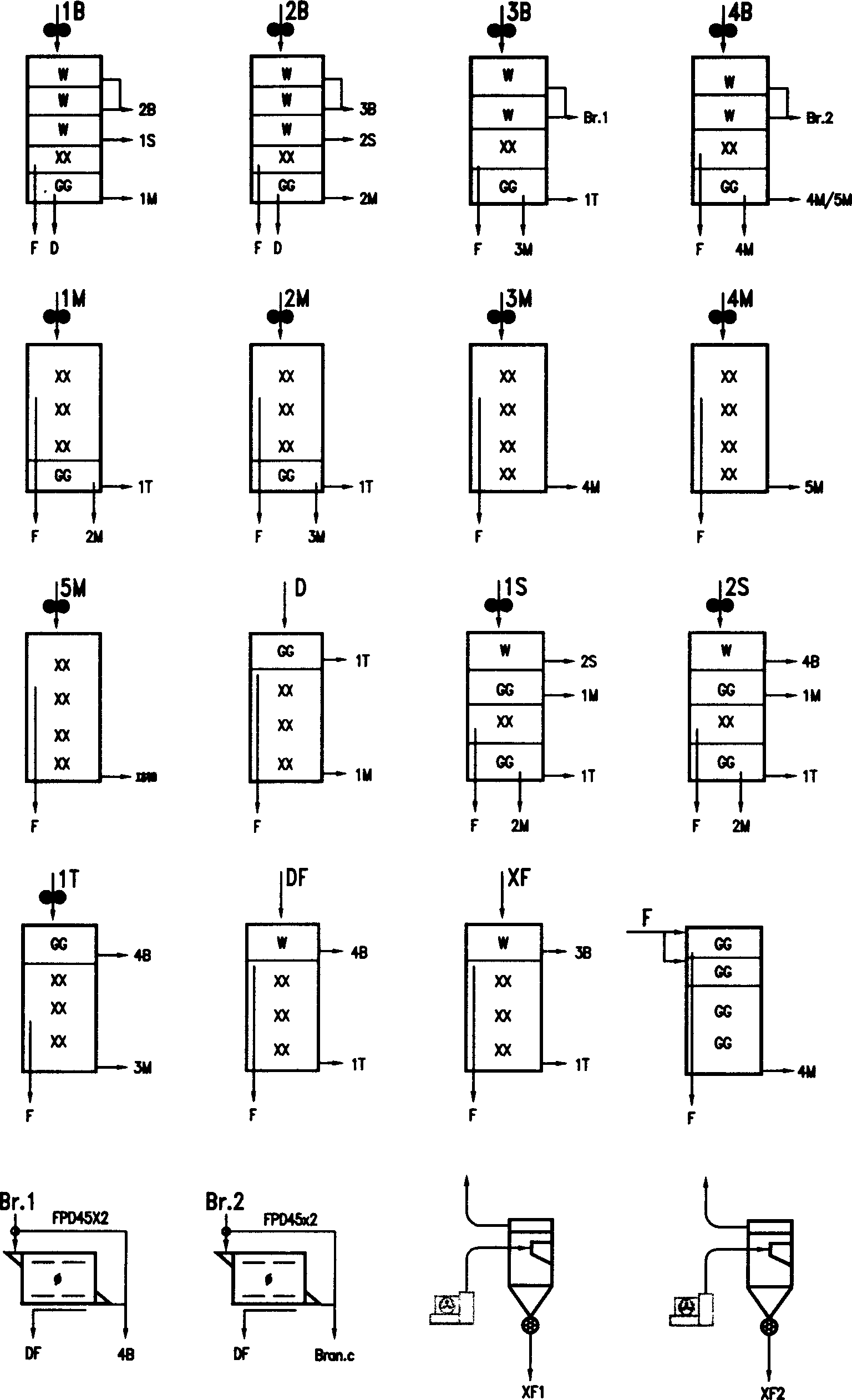

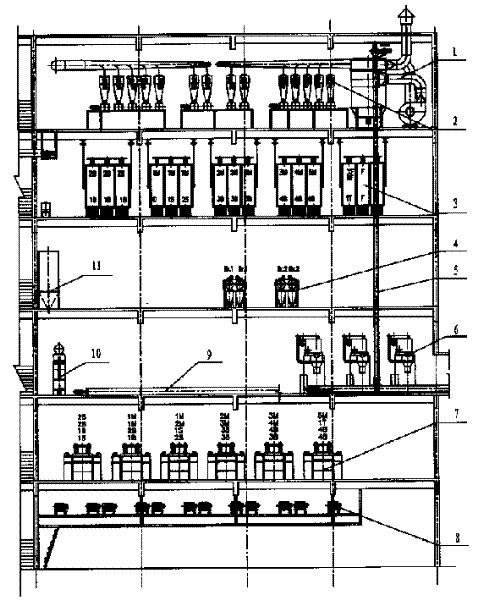

[0020] Embodiment 1: As shown in the figure, the accompanying drawing is a schematic diagram of the present invention, B in the figure and the previous text represents the leather mill, M represents the heart mill, S represents the slag mill, T represents the tail mill, Br represents the bran beating machine, DF Stands for beaten bran powder, XF stands for suction powder, F stands for flour, Bran stands for bran, and D stands for grading sieve. figure 1 Middle: No. 1 is a high-pressure fan, No. 2 is an unloader, No. 3 is a square sieve, No. 4 is a bran beating machine, No. 5 is a hoist, No. 6 is a baler, No. 7 is a mill, No. 8 It is a mill motor, and label 9 is a clean wheat bin, label 10 is a 1B scale, and label 11 is a flour auger.

[0021] The invention includes a skin mill system, a heart mill system, a slag mill system and a tail mill system; four skin mills, five heart mills, two slag mills, one tail mill, and two bran grinding processes are adopted;

[0022] The detail...

Embodiment 2

[0070] The invention includes a skin mill system, a heart mill system, a slag mill system and a tail mill system; four skin mills, four heart mills, two slag mills, one tail mill, and two bran grinding processes are adopted; the process flow And corresponding device is all substantially the same as embodiment 1, only is that the heart grinding is changed into four.

Embodiment 3

[0072] The present invention comprises skin milling system, heart milling system, slag milling system and tail milling system; adopts four skin mills, five heart mills, one slag mill, one tail mill, and two processing techniques for beating bran; its technological process and The corresponding devices are basically the same as in Example 1, except that the slag mill is replaced by one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com