A kind of treatment method of waste desulfurization agent

A treatment method and technology of desulfurizer, applied in the field of metallurgy and material science, to achieve the effects of saving treatment costs, simple, mature and reliable process scheme, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

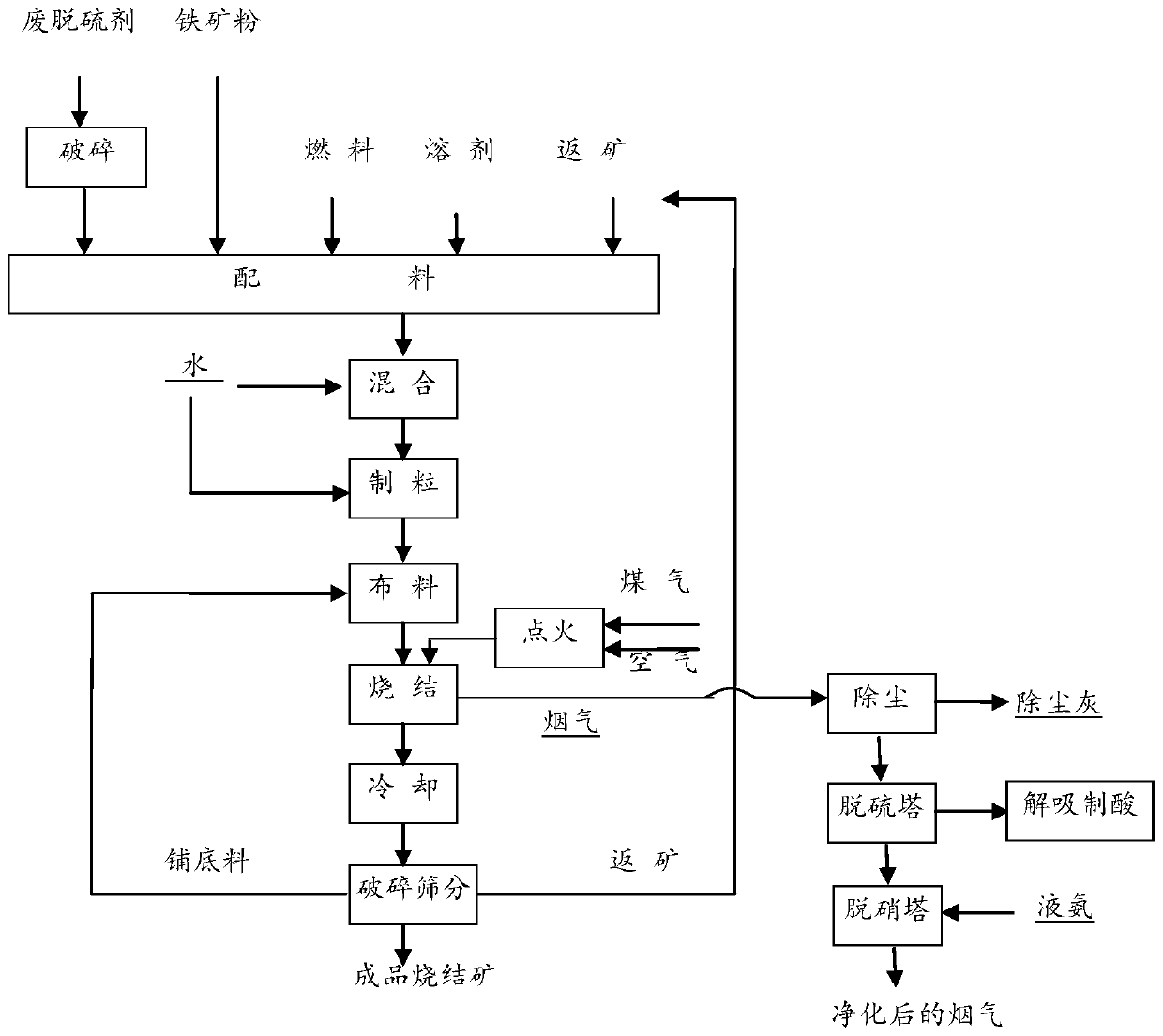

Method used

Image

Examples

Embodiment 1

[0056] A treatment method for waste desulfurizer, comprising the following steps:

[0057] (1) Crushing of waste desulfurizer: take waste desulfurizer, its main chemical composition is 9.10% TFe, 32.29% S, 25.90% CaO, 0.9% MgO, 1.0% SiO 2 ; LOI value was 35.66%. The original particle size of waste desulfurizer is 3-10mm, accounting for 95%, of which 8-10mm accounts for about 35%. Crushing the above waste desulfurizer until the particle size is less than 8mm accounts for 100%.

[0058] (2) Under the set target chemical composition of sinter, the batching calculation is carried out according to the chemical composition of the sintering raw materials used, and the batching ratio of various raw materials required is obtained. The specific steps are:

[0059] Controlling SiO in Sinter Chemical Composition 2 Content 5.0%, MgO content 1.5%, alkalinity R=1.78 under the target value, carry out batching calculation, obtain the mixing ratio of mixture as follows: iron ore homogeneous...

Embodiment 2

[0071] A treatment method for waste desulfurizer, comprising the following steps:

[0072] (1) Crushing of waste desulfurizer: take waste desulfurizer, its main chemical composition is 9.10% TFe, 32.29% S, 25.90% CaO, 0.9% MgO, 1.0% SiO 2 ; LOI value is 35.66%; the original particle size of waste desulfurizer is 3-10mm, accounting for 95%, of which 8-10mm accounts for about 35%. Crushing the above waste desulfurizer until the particle size is less than 8mm accounts for 100%.

[0073] (2) Under the set target chemical composition of sinter, the batching calculation is carried out according to the chemical composition of the sintering raw materials used, and the batching ratio of various raw materials required is obtained. The specific steps are:

[0074] Controlling SiO in Sinter Chemical Composition 2 Content of 5.0%, MgO content of 1.5%, basicity R = 1.78 under the target value of the batching calculation, the mixture ratio is as follows: 59.89% iron ore homogeneous powder...

Embodiment 3

[0085] A treatment method for waste desulfurizer, comprising the following steps:

[0086] (1) Crushing of waste desulfurizer: take waste desulfurizer, its main chemical composition is 9.10% TFe, 32.29% S, 25.90% CaO, 0.9% MgO, 1.0% SiO 2 ; LOI value is 35.66%; the original particle size of waste desulfurizer is 3-10mm, accounting for 95%, of which 8-10mm accounts for about 35%. Crushing the above waste desulfurizer until the particle size is less than 8mm accounts for 100%.

[0087] (2) Under the set target composition of sintering ore, the batching calculation is carried out according to the chemical composition of the sintering raw materials used, and the batching ratio of various raw materials required is obtained. The specific steps are:

[0088] Controlling SiO in Sinter Chemical Composition 2 Content of 5.0%, MgO content of 1.5%, basicity R = 1.78 under the target value of the batching calculation, the mixture ratio is as follows: 59.89% iron ore homogeneous powder 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com