Low-stickiness food noodle maker

A low-viscosity, machine-making technology, applied in dough extruders and other directions, can solve problems such as not achieving the desired effect, and achieve the effect of simple structure, not easy to become rotten, and coarse particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

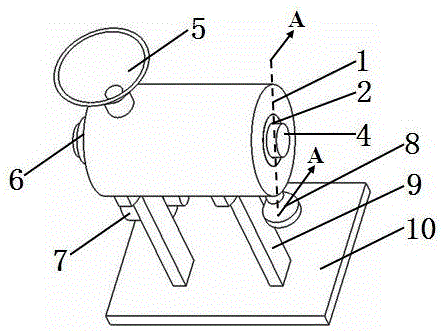

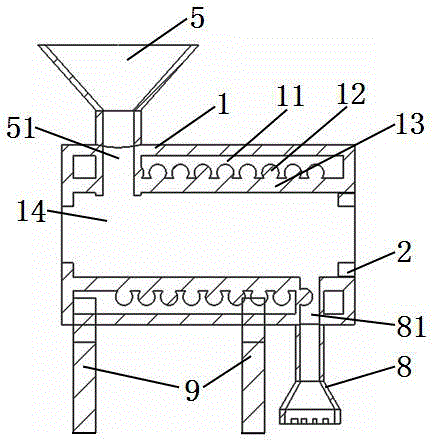

[0030] Please see figure 1 , figure 2 , Figure 5 , Low-viscosity food noodle making machine, characterized in that it includes a housing, a front bearing seat 2, a rear bearing seat, a screw 4, a feeding device 5, a motor 7, a transmission device 6, a discharging and noodle forming device 8, a support 9 , Base 10; one end of the support is fixed on the base, the other end of the support is fixed under the shell, the motor is placed at the left end of the base, the screw is left end body 41, groove 43, first spiral section 44, fine crushing section from left to right. 45. The second spiral section 46, the right end body 42; the shell is composed of an outer shell 1 and an inner shell 13. The inner shell is a hollow screw bore 14. A heating cavity 11 is formed between the inner shell and the outer shell for heating The cavity and the screw bore are not connected, the heating device 12 is installed in the heating cavity; the front bearing seat is fixedly installed at the front en...

Embodiment 2

[0032] Please see figure 1 , figure 2 , Image 6 , Low-viscosity food noodle making machine, characterized in that it includes a housing, a front bearing seat 2, a rear bearing seat, a screw 4, a feeding device 5, a motor 7, a transmission device 6, a discharging and noodle forming device 8, a support 9 , Base 10; one end of the support is fixed on the base, the other end of the support is fixed under the shell, the motor is placed at the left end of the base, the screw is left end body 41, groove 43, first spiral section 44, fine crushing section from left to right. 45. The second spiral section 46, the right end body 42; the shell is composed of an outer shell 1 and an inner shell 13. The inner shell is a hollow screw bore 14. A heating cavity 11 is formed between the inner shell and the outer shell for heating The cavity and the screw bore are not connected, the heating device 12 is installed in the heating cavity; the front bearing seat is fixedly installed at the front end...

Embodiment 3

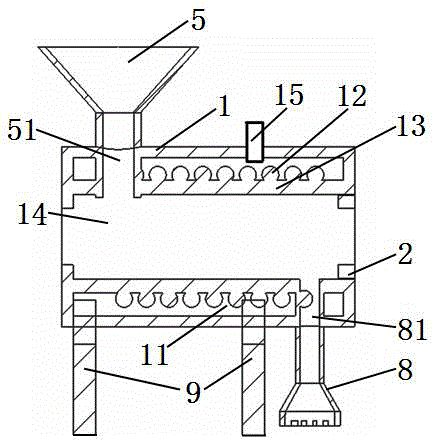

[0035] Please see figure 1 , figure 2 , Figure 7 , Low-viscosity food noodle making machine, characterized in that it includes a housing, a front bearing seat 2, a rear bearing seat, a screw 4, a feeding device 5, a motor 7, a transmission device 6, a discharging and noodle forming device 8, a support 9 , Base 10; one end of the support is fixed on the base, the other end of the support is fixed under the shell, the motor is placed at the left end of the base, the screw is left end body 41, groove 43, first spiral section 44, fine crushing section from left to right. 45. The second spiral section 46, the right end body 42; the shell is composed of an outer shell 1 and an inner shell 13. The inner shell is a hollow screw bore 14. A heating cavity 11 is formed between the inner shell and the outer shell for heating The cavity and the screw bore are not connected, the heating device 12 is installed in the heating cavity; the front bearing seat is fixedly installed at the front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com