Process for recycling molasses alcohol wastewater evaporation and condensation liquid in alcohol fermentation

A technology of molasses alcohol wastewater, evaporation and condensation, applied in the field of alcohol fermentation, can solve the problems of affecting the economic profit of enterprises, high power consumption of aerobic digestion and treatment of evaporative condensate, and improve the utilization rate of raw materials, reduce the occupied area, and reduce the load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

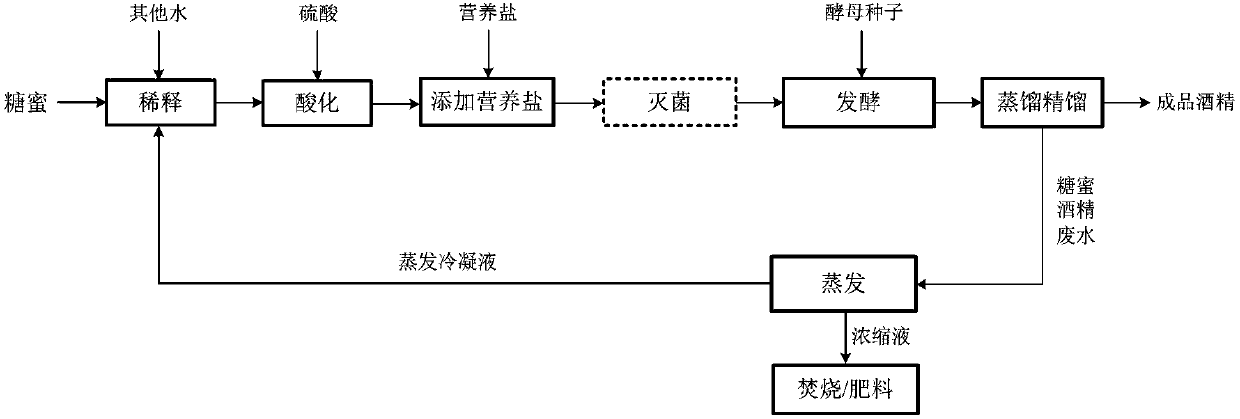

[0027] A kind of technology that the molasses alcohol waste water evaporation condensate of the present invention is used for alcohol fermentation adopts the following process steps:

[0028] Dilute the sugarcane molasses to a concentration of 25% (w / v, sugar concentration) with the evaporation condensate of sugarcane molasses alcohol waste water, add sulfuric acid to adjust the pH to 4.0, add ammonium sulfate (0.1% of molasses, according to the undiluted molasses mass meter, The following relevant content is the same as this), disodium hydrogen phosphate (0.25% of molasses), magnesium sulfate (0.04% of molasses), and the temperature is raised to 85°C for 1h. Cool to 30°C, insert 15% (v / v) yeast seed liquid to start fermentation (after inoculation, the number of yeast in the fermentation liquid reaches 2×10 6 CFU / mL). After fermentation, alcohol and molasses alcohol waste water are obtained through a differential pressure distillation process. The average concentration of ac...

Embodiment 2

[0030] A kind of technology that the molasses alcohol waste water evaporation condensate of the present invention is used for alcohol fermentation adopts the following process steps:

[0031] Dilute beet molasses to a concentration of 25% with beet molasses alcohol wastewater evaporation condensate, add sulfuric acid to adjust pH to 4.0, calcium phosphate (1% of molasses, according to the undiluted molasses mass, the following relevant content is the same)), sulfuric acid Magnesium (0.04% of molasses), the temperature was raised to 85°C and maintained for 1h. Cool to 30°C, insert 15% (v / v) yeast seed solution to start fermentation. After fermentation, the process of atmospheric distillation obtains alcoholic and molasses alcoholic wastewater. The average concentration of acetic acid in this molasses alcohol wastewater is 374mg / L. The molasses alcohol wastewater is evaporated through multi-effect evaporation to obtain evaporation condensate, which is reused for the next batch...

Embodiment 3

[0033] A kind of technology that the molasses alcohol waste water evaporation condensate of the present invention is used for alcohol fermentation adopts the following process steps:

[0034] Mix beet molasses alcohol wastewater evaporation condensate with groundwater at a volume ratio of 1:1, dilute beet molasses to a concentration of 22% with mixed water, add sulfuric acid to adjust pH to 3.8, calcium phosphate (1% of molasses, according to the undiluted Molasses mass meter, the following relevant content is the same as this)), magnesium sulfate (0.04% of molasses). Insert 15% (v / v) yeast seed solution to start fermentation. After fermentation, alcohol and molasses alcohol waste water are obtained through a differential pressure distillation process. The average concentration of acetic acid in this molasses alcohol wastewater is 329mg / L. The molasses alcohol waste water is evaporated through multi-effect evaporation to obtain evaporation condensate, which is reused for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com