High fermentation rate type recombinant alcoholic fermentation yeast, the building and expression carrier thereof

A technology of alcohol yeast and fermentation rate, which is applied in the direction of introducing foreign genetic material, fermentation, and recombinant DNA technology by using carriers, and can solve problems such as increasing the complexity of alcohol fermentation process operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

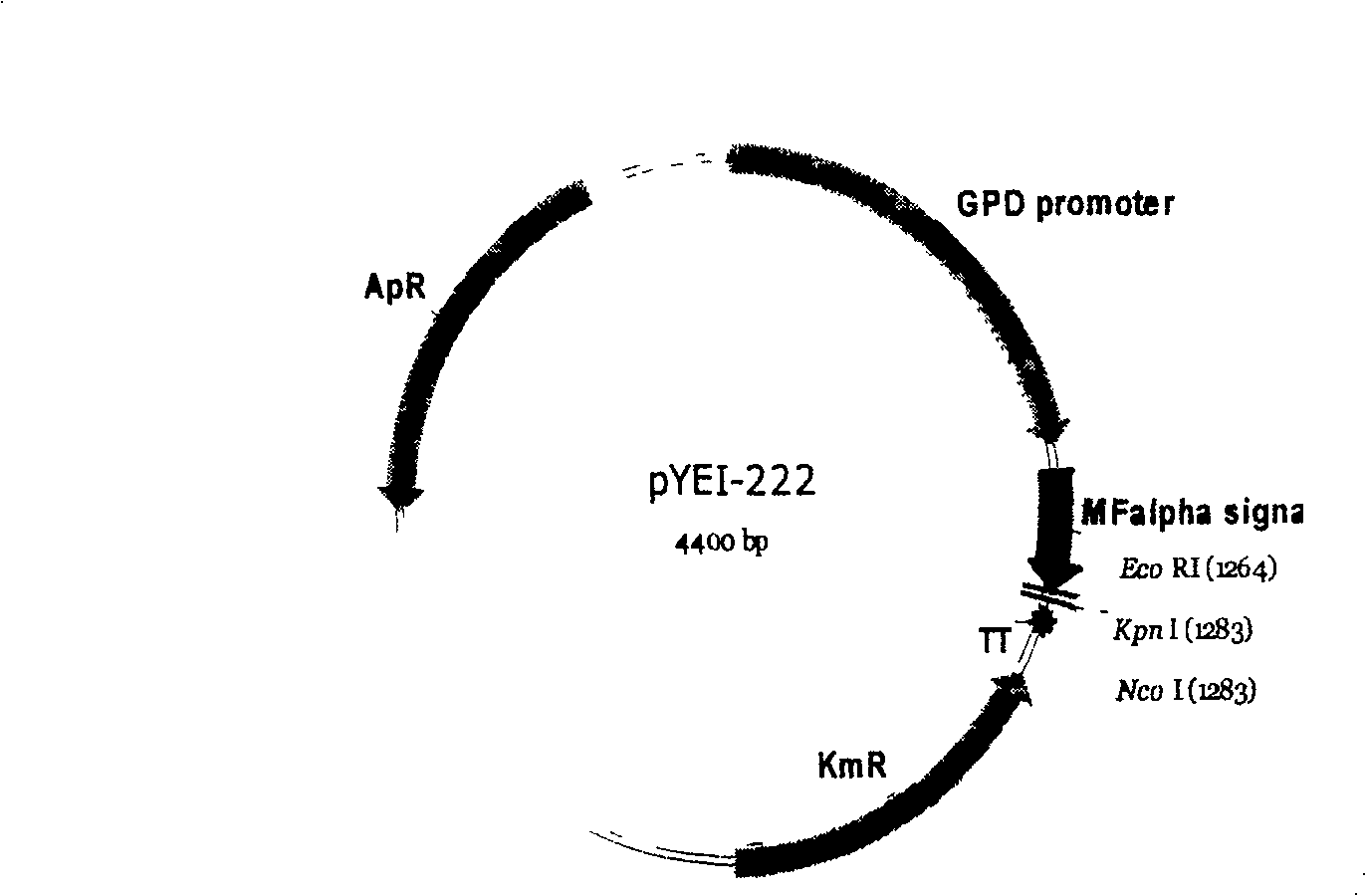

[0129] Embodiment 1: Construction of yeast expression vector

[0130] The primers used in the construction of yeast expression vectors were synthesized by a DNA synthesizer. The primers used are as follows:

[0131] Primer P1: cg agatct ct attttcgagg accttgtcac

[0132] Primer P2: tttgtttgtt tatgtgtgtt

[0133] Primer P3: ttataagacg ggcaaaata

[0134] Primer P4: taaccaa ttctgattag aaa

[0135] Primer P5: ttt agatct a acgggaaacg tcttgct

[0136] Primer P6: aac agatct c tgcctcgcgc gtttcggtga t

[0137] Primer P7: tcg agatct c gaataataac tgttattttt ca

[0138] The single underlined part is the artificially introduced restriction enzyme cutting site; the double underlined part is the sequence artificially introduced to facilitate splicing of fragments.

[0139] The construction process of the expression vector is as follows:

[0140] Synthetic S MFα And in the process of synthesis, multiple cloning sites and transcription termination sequences T art And a p...

Embodiment 2

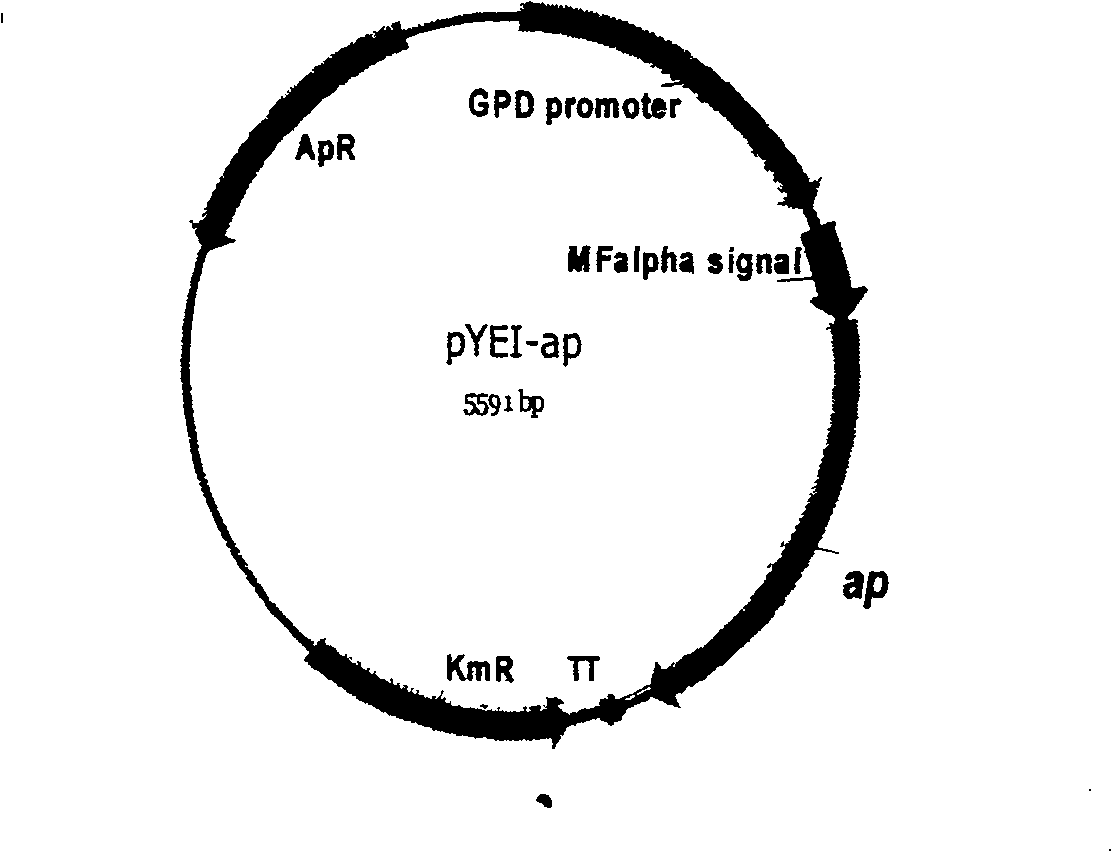

[0141] Embodiment 2: the construction of alcohol yeast expression acid protease gene ap recombinant plasmid

[0142] The acid protease gene ap was cloned by using the PCR technique, using the chromosomal DNA or total RNA of the filamentous fungus as a template, and mediated by a pair of specific primers. The artificially designed and synthesized primers for acid protease gene cloning and expression, its characteristic sequence is:

[0143] An-Ap1:acat gaattc atggtcgtct tcagcaaaac cgctgccctc

[0144] An-Ap2: gtga gaattc ttttttttttttttttttttt

[0145] Af-Ap1:acat gaattc atggctccat tcacgtttct ggtagggata

[0146] Af-Ap2: gtga gaattc tcatggggta cttgaaacac tcgtggccaa t

[0147] Ao-Ap1:acat gaattc atgatgcggg gcgcatctct cctaccagtt

[0148] Ao-Ap2: gtga gaattc ttacaaagca agaagaagac cagcacccgc a

[0149] Mp-Ap1:acat gaattc atggtcgtct tcagcaagat caccgccgtt

[0150] Mp-Ap2: gtga gaattc ttacaaagca agaagaagac cagcacccg

[0151] Nc-Ap1:acat gaattc atgtcttcga...

Embodiment 3

[0157] Example 3: Construction of recombinant industrial alcohol production yeast CICIM MMY0034 (CCTCC M206009)

[0158] The activated industrial alcohol-producing strain Saccharomyces cerevisiae 825 was cultured in 500mL YPD (1% yeast extract, 2% peptone, 2% glucose) at 30°C for 18h until OD 600 =1.7, 5000r / min centrifugation collects the thalline, successively washes the thalline with 500mL, 250mL precooled sterile water, centrifuges to remove the supernatant, and suspends the thalline with 20mL precooled 1mol / L sorbitol. After centrifugation, the bacteria were suspended in 0.5 mL pre-cooled sorbitol, and used as competent cells for electroshock transformation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com