Treatment method and device of rice lees wastewater

A treatment method and technology of rice distiller's grains, which can be used in food industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., which can solve the problems of large amount of sludge, large area and high operating cost. , to achieve the effect of reducing operating costs, equipment costs, and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

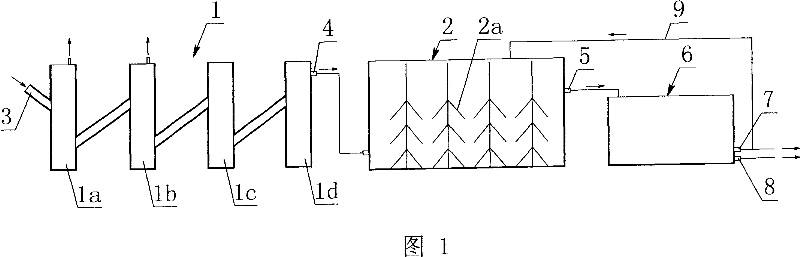

[0014] Referring to shown in Fig. 1, the treatment device of rice distiller's grain wastewater of the present invention comprises anaerobic treatment pond 1, aerobic treatment pond 2, and this anaerobic treatment pond 1 is made up of first-stage anaerobic pond 1a, second-stage anaerobic Pool 1b, the third-stage anaerobic pond 1c and the fourth-stage anaerobic pond 1d are connected in series, and a liquid inlet 3 is provided on the top of the first-stage anaerobic pond 1a, and the bottom of the first-stage anaerobic pond 1a is connected to the second-stage anaerobic pond 1a. The upper part of the secondary anaerobic tank 1b communicates, the lower part of the second-level anaerobic tank 1b communicates with the upper part of the third-level anaerobic tank 1c, the lower part of the third-level anaerobic tank 1c communicates with the upper part of the fourth-level anaerobic tank 1d Connected, the top of the fourth-stage anaerobic tank 1d is provided with a first liquid outlet 4, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com