Preparation process of lithium battery electrode plate

An electrode pole piece and preparation process technology, applied in the field of lithium battery electrode pole piece preparation technology, can solve problems such as uneven mixing, pole piece cracking, complex process, etc., to improve safety, reduce proportion, and save workshop area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

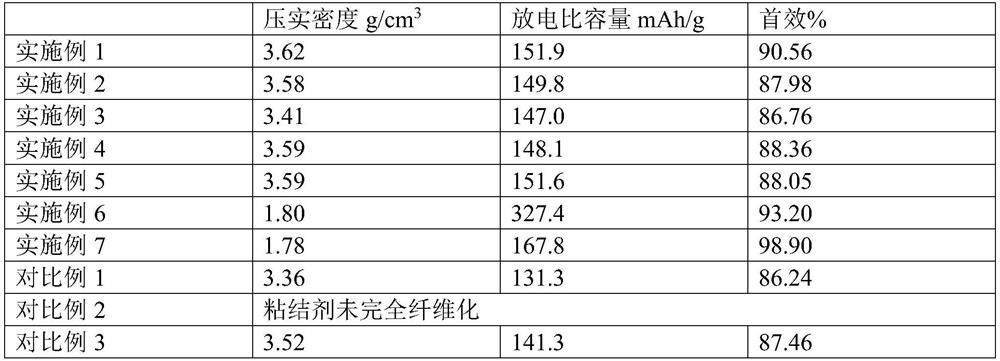

Embodiment 1

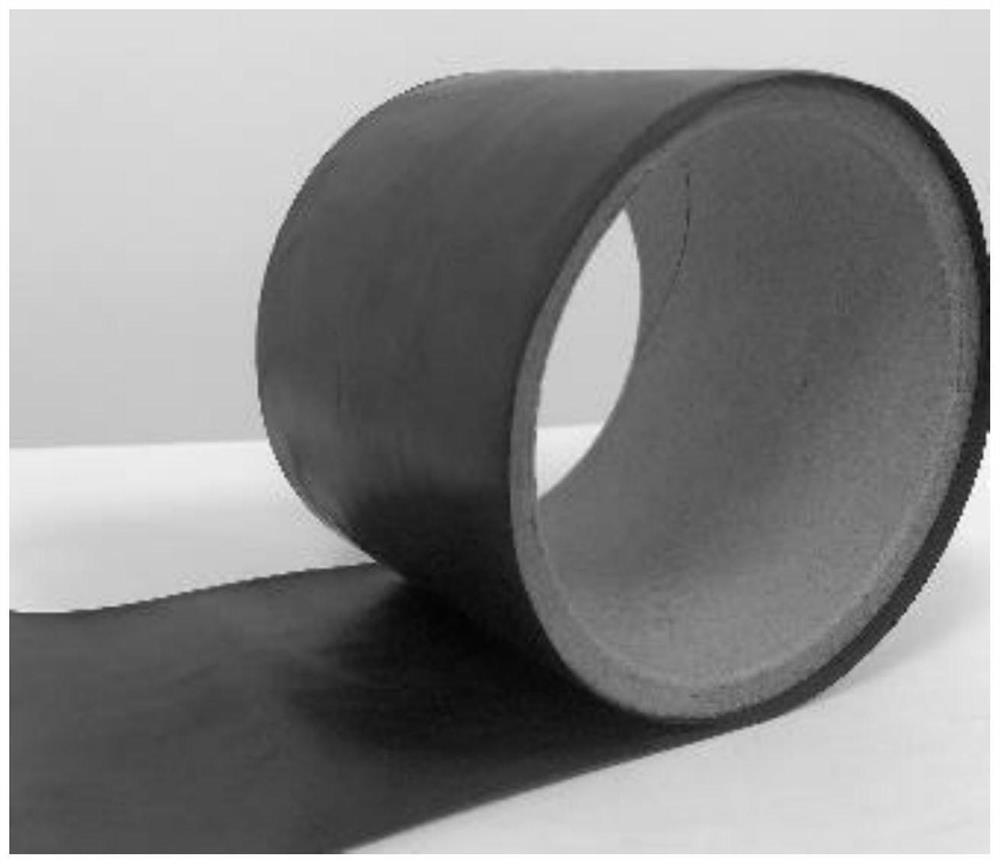

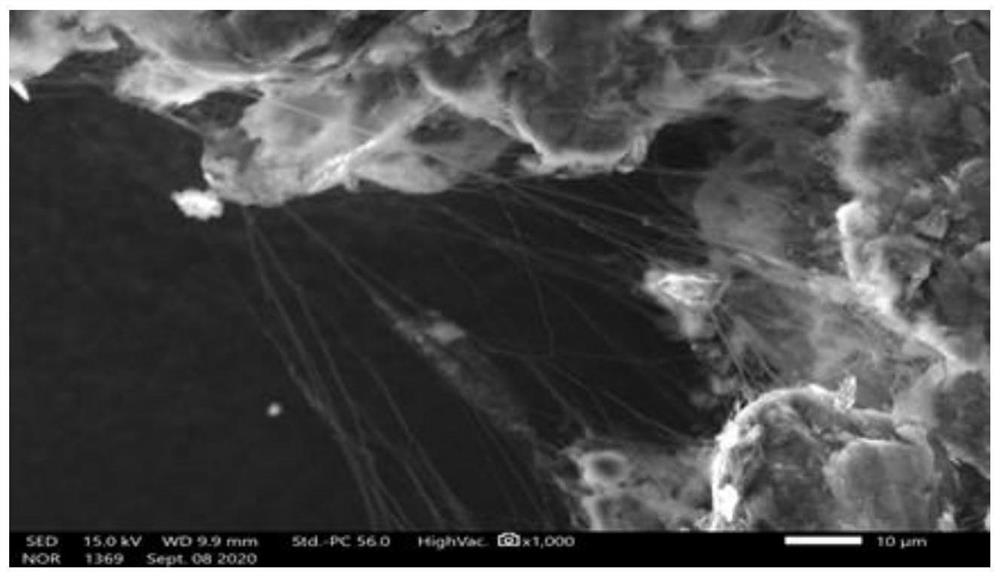

[0033] Batching 100g, wherein at first 92g ternary 523 (LiNi 0.5 co 0.2 mn 0.3 o 2), 4g conductive agent (graphene and SP mass ratio 1:1) were added to the mixer, stirred at low speed (600rpm) for 8-10min, mixed evenly, then added 4g polytetrafluoroethylene, stirred at high speed (20000rpm) for 10-20s, stopped 1-2min, and then stir for 10-20s to fully fiberize PTFE; add 5g (mass ratio 20:1) auxiliary isoparaffin solvent oil (commercially available, boiling point 114°C), stir at high speed (20000rpm) for 10s to fluffy (like marshmallow). Put the mixed flocculent mixture into a mortar and roll it into shape, then put it into a roller press, roll it hot at 80°C to form a film, and roll it to a certain compaction density to form a self-supporting pole piece film ( see figure 1 ), dried in a vacuum oven at 120°C for 8 hours to remove additives, and finally hot-pressed with a current collector to obtain a positive electrode sheet.

[0034] like figure 1 , is a self-supporting...

Embodiment 2

[0037] Ingredients 100g, among which first add 94g ternary 523, 4g conductive agent (graphene and Ketjen black mass ratio 1:1) into the mixer, stir at low speed (800rpm) for 8-10min, mix well, then add 2g polytetrafluoroethylene , stir at high speed (25000rpm) for 10-20s, stop for 1-2min, and then stir for 10-20s to fully fiberize the polytetrafluoroethylene; add 5g (mass ratio 20:1) of petroleum ether, stir at high speed (25000rpm) for 10s until the flocculation shape. Put the mixed flocculent mixture into a mortar and roll it into shape, then put it into a roller press, roll it hot at 80°C to form a film, and roll it to a certain compaction density to form a self-supporting pole piece film. Dry in a vacuum oven at 120°C for 8 hours to remove additives, and finally hot press with a current collector to obtain a positive electrode sheet.

Embodiment 3

[0039] The ingredients are 100g, among which 96g of ternary 523 and 2g of conductive agent (SP) are first added to the mixer, stirred at a low speed (800rpm) for 8-10min, mixed evenly, then added 2g of polytetrafluoroethylene, stirred at a high speed (25000rpm) for 10-20s, Stop for 1-2min, then stir for 10-20s to fully fiberize the PTFE; add 5g of absolute ethanol, stir at high speed (25000rpm) for 10s until flocculent. Put the mixed flocculent mixture into a mortar and roll it into shape, then put it into a roller press, roll it hot at 80°C to form a film, and roll it to a certain compaction density to form a self-supporting pole piece film. Dry in a vacuum oven at 120°C for 8 hours to remove additives, and finally hot press with a current collector to obtain a positive electrode sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com