Continuous-chromatography separating and purifying method of etimicin sulfate

A technology of etimicin sulfate and continuous chromatography, which is applied in the field of separation and purification of antibacterial drug etimicin, can solve the problems of large consumption of water and eluent, low purity of etilmicin, and high environmental protection pressure, and achieves High resin utilization rate, optimized purity and yield, and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

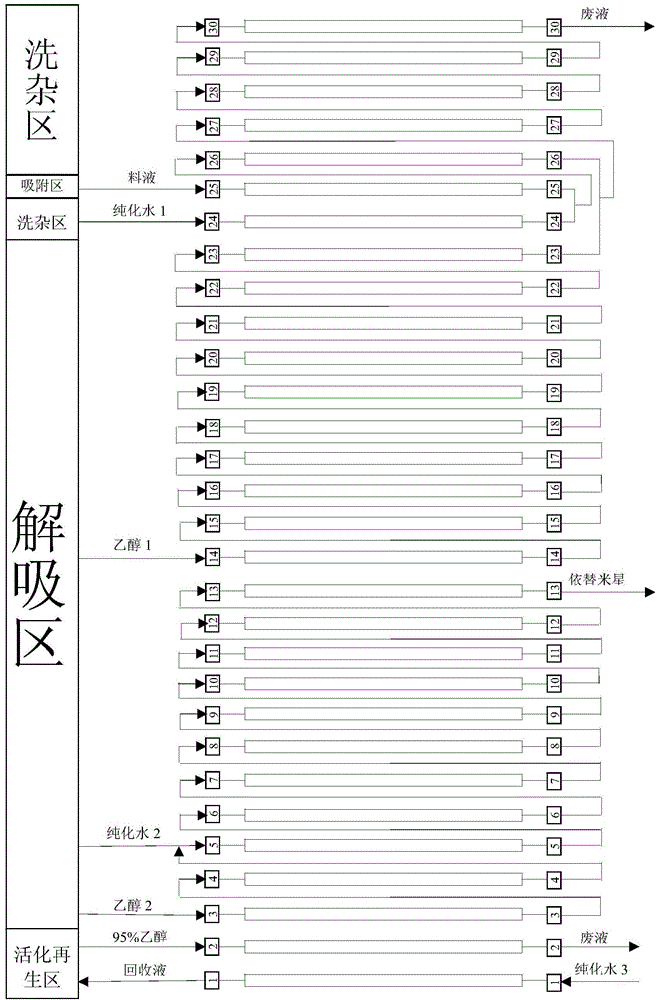

[0047] Combine below figure 1 And the embodiment is described in detail:

[0048] The selected resin of the present invention is No. 1 resin of Huazhen chromatography, and the resin particle diameter is more than 95% of 100 orders, and the filling capacity of each resin column is 0.08m 3 , the capacity of the resin column is 0.1m 3 , the actual filling ratio is 80%. The total size of the system is 3m×3m×5m (length×width×height).

[0049] The disc transfer type continuous chromatographic separation system separates etimicin into the following areas:

[0050] 1) Adsorption area: (Unit 25)

[0051] There is one unit (unit 25) in this area. Through flow rate control, the raw materials first enter unit 25, and then enter unit 27 in series for cleaning.

[0052] 2) Laundry area: (Units 24, 26-30)

[0053]After adsorption, each resin needs to be washed with water, located before and after the adsorption area. After the resin column rotates to the adsorption washing area, the m...

Embodiment 2

[0068] Combine below figure 1 And the embodiment is described in detail:

[0069] The selected resin of the present invention is YPR-II resin, and the resin is 80 mesh, and the filling capacity of each resin column is 0.08m 3 , the capacity of the resin column is 0.1m 3 , the actual filling ratio is 80%. The total size of the system is about 3m×3m×5m (length×width×height).

[0070] The simulated moving bed continuous chromatographic separation system separates etimicin into the following areas:

[0071] 1) Adsorption area: (Unit 25)

[0072] There is one unit (unit 25) in this area. Through flow rate control, the raw materials first enter unit 25, and then enter unit 27 in series for cleaning.

[0073] 2) Laundry area: (Units 24, 26-30)

[0074] After adsorption, each resin needs to be washed with water, located before and after the adsorption area. After the resin column rotates to the adsorption washing area, the material liquid (mainly clarified liquid) entrained in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com