Method for producing 1,3-propylene glycol

A production method, the technology of propylene glycol, applied in the field 1, can solve the problems of low safety, difficulty in expanding production, long production cycle, etc., and achieve the effect of highlighting substantive features, facilitating investment in production, and expanding production scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

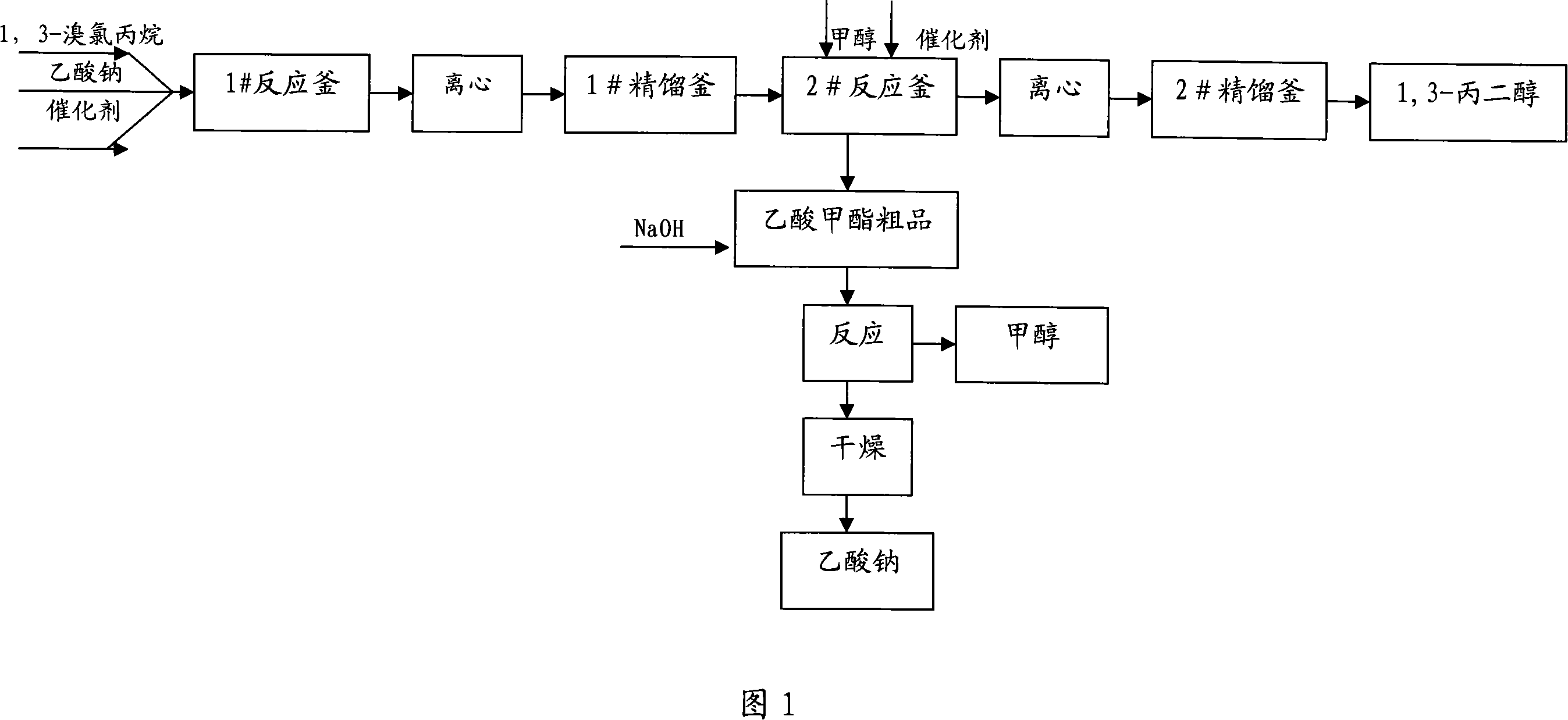

Image

Examples

Embodiment 1

[0030] Put 157.5kg of 1,3-bromochloropropane (100%, the same below), 164kg of sodium acetate (100%, the same below) and 0.315kg (100%, the same below) methanol into the reactor, mechanical stirring, steam Heating, when the temperature of the kettle rises to (130±2)°C, keep the temperature for about 2 hours, then continue to heat up, when the temperature of the kettle reaches (150±2)°C, reduce the steam flow, keep the temperature for about 6 hours, and then cool down to ( 40±2)°C, sampling and analysis.

[0031] After the reaction is over, start centrifugation, divide the solid-liquid mixture in the kettle into the centrifuge 5-6 times, the centrifuge speed can reach 1000 rpm, and turn on the centrifuge for about 15 minutes each time to completely separate the solid and liquid.

[0032] The centrifuged liquid phase is sucked into the rectification kettle by vacuum, and the rectification starts under the conditions of vacuum degree of -720mm Hg and oil bath temperature (190±5)°C...

Embodiment 2

[0035] Put 157.5kg of 1,3-bromochloropropane, 328kg of sodium acetate and 1.575kg of methanol into the reaction kettle, stir mechanically, and heat with steam. When the temperature of the kettle rises to (130±2)°C, keep the reaction for about 2 hours, and then continue to heat up , When the temperature of the kettle reaches (150±2)°C, reduce the steam flow rate, keep the temperature for about 6 hours, then lower the temperature to (40±2)°C, and take samples for analysis.

[0036] After the reaction is over, start centrifugation, divide the solid-liquid mixture in the kettle into the centrifuge 5-6 times, the centrifuge speed can reach 1000 rpm, and turn on the centrifuge for about 15 minutes each time to completely separate the solid and liquid.

[0037] The centrifuged liquid phase is sucked into the rectification kettle by vacuum, and the rectification starts under the conditions of vacuum degree of -720mm Hg and oil bath temperature (190±5)°C. When there is evaporation in th...

Embodiment 3

[0040] Put 157.5kg of 1,3-bromochloropropane, 246kg of sodium acetate and 0.788kg of methanol into the reaction kettle, stir it mechanically, and heat it with steam. When the temperature of the kettle rises to (130±2)°C, keep it warm for about 2 hours, and then continue heating Raise the temperature, when the temperature of the kettle reaches (150±2)°C, reduce the steam flow rate, keep the temperature for about 6 hours, then lower the temperature to (40±2)°C, and take samples for analysis.

[0041] After the reaction is over, start centrifugation, divide the solid-liquid mixture in the kettle into the centrifuge 5-6 times, the centrifuge speed can reach 1000 rpm, and turn on the centrifuge for about 15 minutes each time to completely separate the solid and liquid.

[0042] The centrifuged liquid phase is sucked into the rectification kettle by vacuum, and the rectification starts under the conditions of vacuum degree of -720mm Hg and oil bath temperature (190±5)°C. When there i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com