Preparation method of graphene-PVC composite material

A composite material and graphene technology, applied in the field of graphene-PVC composite material preparation, can solve the problems of high production consumption, low regularity of composite resin particles, low utilization rate of free radical initiators, etc. The effect of reducing the investment in fixed assets and fully applying the potential of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

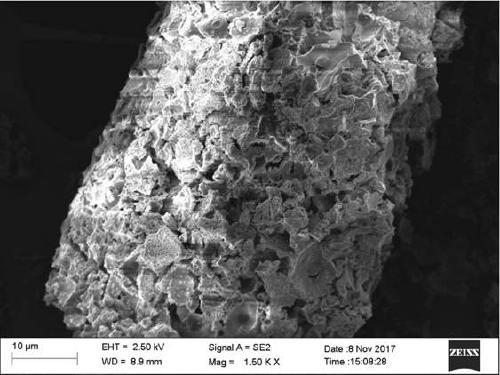

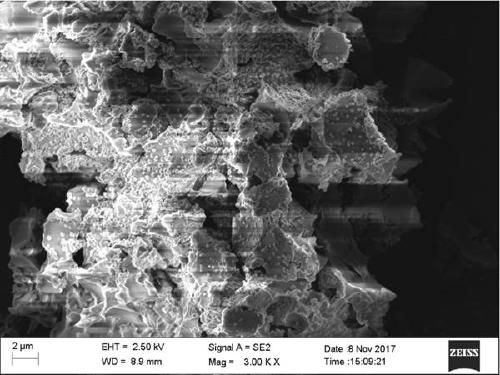

Image

Examples

Embodiment 1

[0022] The object of the present invention is to provide a method for preparing graphene-PVC composite materials in one pot. The preparation process can start from relatively simple and easy-to-obtain raw materials, and directly obtain molecules with complex structures without separation of intermediates. Such preparation is obviously economically and environmentally friendly. The purpose of improving the performance of PVC composite materials by adding graphene oxide slurry.

[0023] The preparation steps of the present invention are as follows: adopt a 500ml three-necked round bottom flask, add 100 ml PVC slurry at room temperature, mechanically stir to make PVC particles evenly suspended in the water phase at 3500r / min for 10 min; add 80 ml GO slurry, Stir and mix uniformly at a speed of 700 r / min for 10 min; heat up to 80 o C, according to the mass ratio of GO to 4:1, add L-ascorbic acid, stir and react for 2 h; after the reaction, cool down to 50 oC Next, centrifuge at...

Embodiment 2

[0025] The object of the present invention is to provide a kind of one-pot method to prepare the method preparation step of graphene-PVC composite material and be: adopt 500ml three-necked round bottom flask, add 150 ml PVC slurry under room temperature, mechanical stirring makes PVC particle, evenly suspend 3500r / min in the water phase, time 10 min; add 80 ml GO slurry, stir and mix evenly, speed 700 r / min, time 10 min; heat up to 80 o C, according to the mass ratio of GO to 4:1, add L-ascorbic acid, stir and react for 2 h; after the reaction, cool down to 50 oC Next, centrifuge at a speed of 1000 r / min for 20 minutes or stand still for 24 hours; dry and sieve to obtain functionalized graphene / PVC resin.

Embodiment 3

[0027] The object of the present invention is to provide a kind of one-pot method to prepare the method preparation step of graphene-PVC composite material and be: adopt 500ml three-necked round-bottomed flask, add 200 ml PVC slurry under room temperature, mechanical stirring makes PVC particle, evenly suspend 3500r / min in the water phase, time 10 min; add 80 ml GO slurry, stir and mix evenly, speed 700 r / min, time 10 min; heat up to 80 o C, according to the mass ratio of GO to 4:1, add L-ascorbic acid, stir and react for 2 h; after the reaction, cool down to 50 oC Next, centrifuge at a speed of 1000 r / min for 20 minutes or stand still for 24 hours; dry and sieve to obtain functionalized graphene / PVC resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com