Copper smelting device with high-oxygen-enrichment double-side-blowing melting bat and operation method of copper smelting device

A copper smelting device and oxygen-enriched technology, which is applied to crucible furnaces, electric furnaces, rotary drum furnaces, etc., can solve the problems of poor operating environment for workers, increased production costs, and increased heat loss, so as to improve the utilization rate of plant space and reduce production costs. The effect of reduction, yield reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

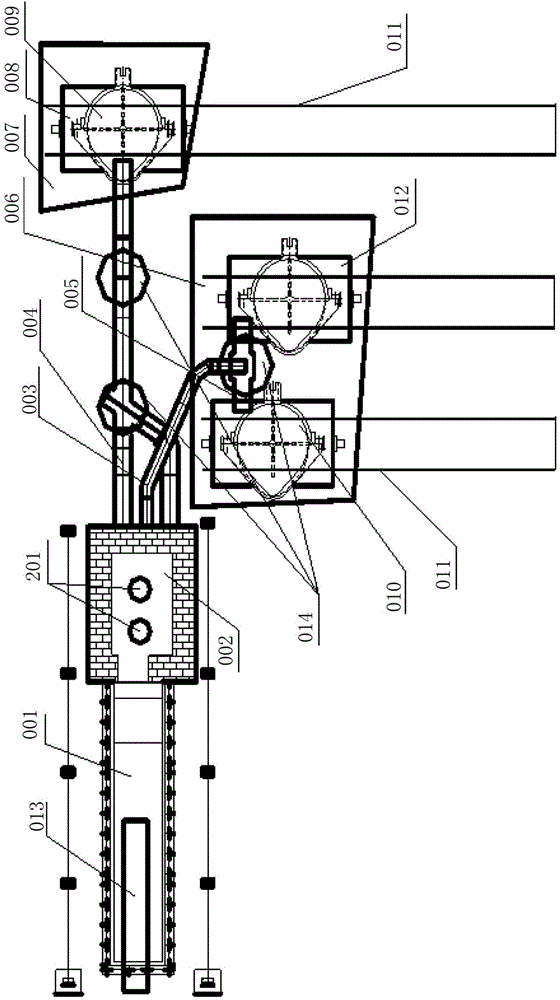

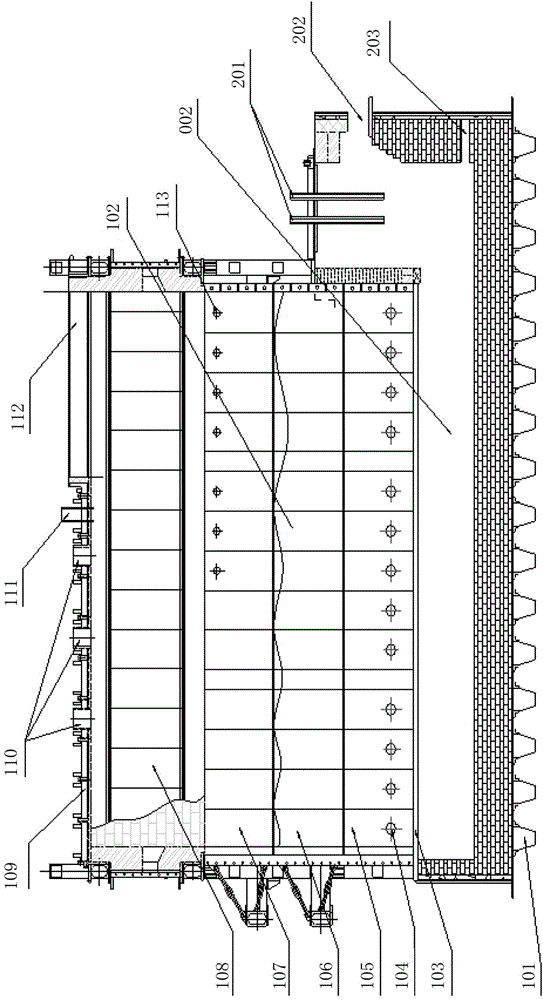

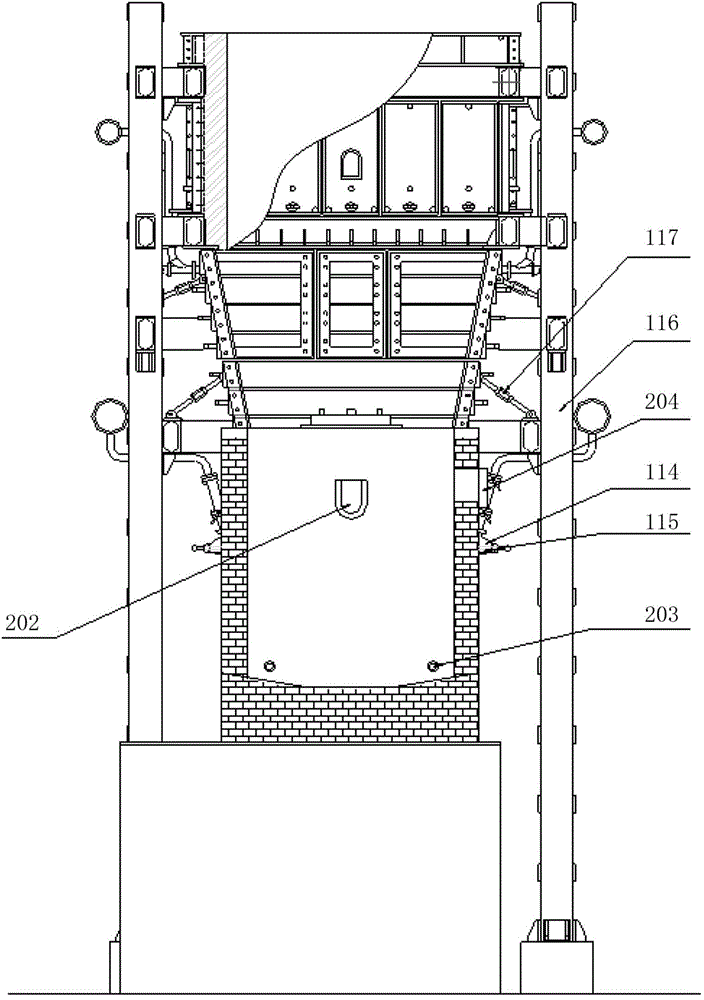

[0024] Such as figure 1 , figure 2 , image 3As shown, this invention designs a high-oxygen-enriched double-side blowing molten pool copper smelting device. Private room 006, matte private room 007, matte rail car 008, matte copper bag 009, smelting slag bag 010, rail 011, smelting slag rail car 012, feeding belt 013, smoking hood 014, melting furnace foundation 101, Furnace body 102, furnace platform water jacket 103, primary tuyere 104, first-layer water jacket 105, second-layer water jacket 106, third-layer water jacket 107, fourth-layer water jacket 108, furnace top water jacket 109, feeding port 110, third-layer water jacket 111 , rising flue inlet 112, secondary air outlet 113, primary air nozzle 114, marble valve 115, steel column 116, adjusting rod 117, electrode 201, smelting slag outlet 202, matte copper outlet 203 and safety outlet 204. Wherein, the bottom of the smelting furnace 001 is a smelting furnace foundation 101 made of concrete masonry, and on the smelt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com