Divergent split-tooth stepped magnetic fluid rotating sealing device

A rotary seal and magnetic fluid technology, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problem that the pressure resistance effect cannot be well achieved, the axial pole tooth pressure resistance effect is reduced, and the height of the shaft shoulder cannot be large and other problems, to achieve the effect of improving the magnetic concentration effect, solving the insufficient pressure resistance capacity, improving the pressure resistance capacity and sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

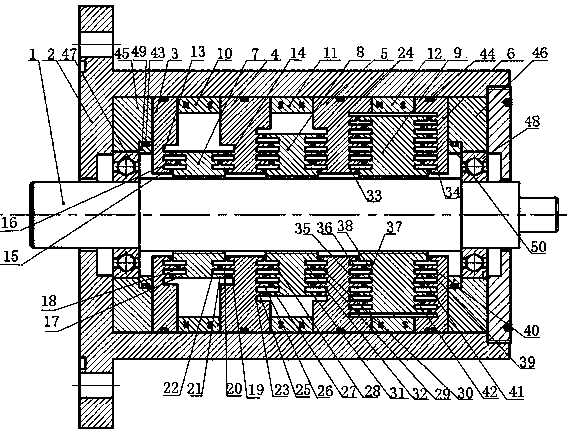

[0043] The present invention will be further described below in conjunction with accompanying drawing.

[0044] Such as figure 1 As shown, the divergent split-tooth stepped magnetic fluid rotary seal device includes a shaft 1, a housing 2, a first pole shoe ring 3, a second pole shoe ring 4, a third pole shoe ring 5, and a fourth pole Boot ring 6, first sleeve 7, second sleeve 8, third sleeve 9, first permanent magnet ring 10, second permanent magnet ring 11, third permanent magnet ring 12;

[0045] The first pole shoe ring 3 , the second pole shoe ring 4 , the third pole shoe ring 5 , and the fourth pole shoe ring 6 are sequentially arranged on the inner wall of the housing 2 from left to right. The first pole shoe ring 3 , the second pole shoe ring 4, the third pole shoe ring 5, and the fourth pole shoe ring 6 extend radially toward the outer circular surface of the shaft 1, leaving a gap between them and the outer circular surface of the shaft 1;

[0046] The first perman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com