System and method for preparing activated carbon from waste circuit boards

A technology for preparing activated carbon and waste circuit boards, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of activated carbon production technology and backward production equipment, achieve easy operation, reduce heat loss, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

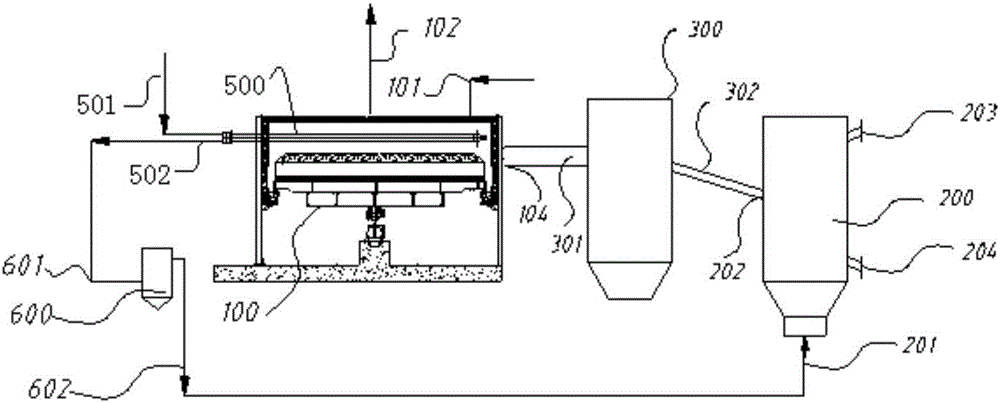

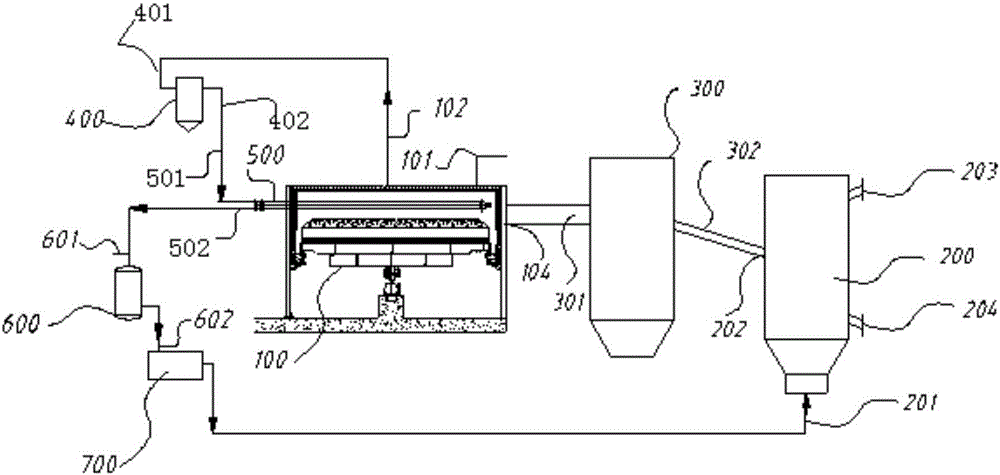

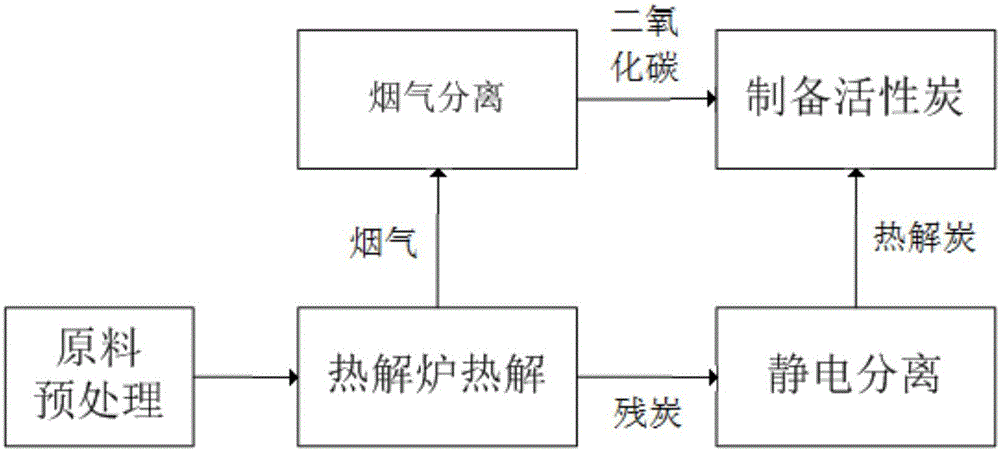

[0062] Using waste circuit boards as raw materials, the method of preparing activated carbon by using waste circuit boards to prepare activated carbon system is as follows:

[0063] Crushing 4.5 tons of waste circuit boards to obtain crushed materials with a particle size below 2mm;

[0064] The broken waste circuit boards are sent to the pyrolysis furnace for pyrolysis, and the materials are uniformly distributed on the distribution board, and the thickness of the material layer is 120mm. A burner is installed in the pyrolysis furnace, and charcoal residue (temperature is about 550° C.) and pyrolysis oil gas (temperature is about 600° C.) are obtained by pyrolysis.

[0065] The generated carbon residue product is sent to the electrostatic separator to separate the metal, and then the pyrolytic carbon is obtained, and the pyrolytic carbon is sent to the fluidized bed;

[0066] The pyrolysis oil gas produced by pyrolysis is sent to the cooling and purification device for cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com