Method for preventing and treating dioxin in waste lithium battery pyrolysis process

A technology for waste lithium batteries and dioxins, applied in the field of dioxin prevention and control, can solve the problems of not considering dioxin prevention and metallurgy methods, excluding dioxins, etc., and achieve the effect of suppressing dioxin production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

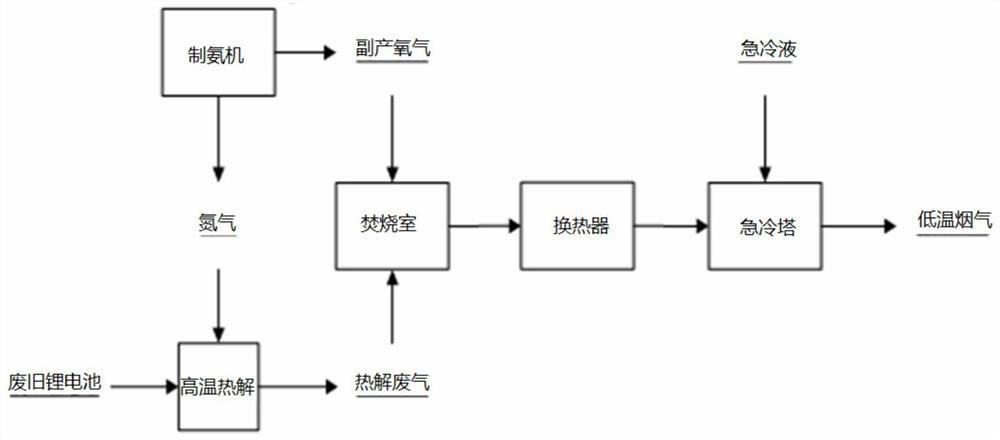

Embodiment 1

[0027] The ternary waste lithium battery is passed into the pyrolysis furnace in a broken form for pyrolysis, and the nitrogen gas is controlled to pass through the pyrolysis furnace, so that the environment of the pyrolysis process is in an oxygen-poor state, and the waste gas generated during the pyrolysis process is sent to the environmental protection treatment system, using high pressure Spray into the incinerator, use natural gas to support combustion when starting the furnace, control the combustion temperature at 900°C, and at the same time, spray the oxygen-enriched gas produced by the nitrogen-making mechanism into the incinerator at high pressure, and the oxygen-enriched gas forms a flame vortex together with the exhaust gas , fully mixed and burned, the burning time is more than 2 seconds. After incineration, the flue gas passes through the heat exchanger, and the temperature of the flue gas drops to 630°C, and then the flue gas passes through the quenching tower, a...

Embodiment 2

[0030] The lithium iron phosphate waste lithium battery is passed into the pyrolysis furnace for pyrolysis by shell shearing, and the nitrogen gas is controlled to pass through the pyrolysis furnace, so that the environment of the pyrolysis process is in an oxygen-poor state, and the waste gas generated during the pyrolysis process is transported to the environmental protection treatment system. It is sprayed into the incinerator in a high-pressure way, and natural gas is used to support combustion when the furnace is turned on, and the combustion temperature is controlled at 930°C. At the same time, the oxygen-enriched gas produced by the nitrogen-making mechanism at the same time is injected into the incinerator in a high-pressure way, and the oxygen-enriched gas is formed together with the exhaust gas. The flame is vortex, fully mixed and burned, and the burning time is more than 2 seconds. After incineration, the flue gas passes through the heat exchanger, the temperature o...

Embodiment 3

[0033] Pass the 3C waste lithium battery into the pyrolysis furnace as a whole for pyrolysis, control nitrogen to pass through the pyrolysis furnace, make the pyrolysis process environment in an oxygen-poor state, and the waste gas generated during the pyrolysis process is sent to the environmental protection treatment system, and sprayed with high pressure In the incinerator, natural gas is used to support combustion when the furnace is turned on, and the combustion temperature is controlled at 950°C. At the same time, the oxygen-rich gas produced by the nitrogen-making mechanism and nitrogen is injected into the incinerator at high pressure. The oxygen-rich gas forms a flame vortex together with the exhaust gas. Combustion occurs when fully mixed, and the combustion time is more than 2 seconds. After incineration, the flue gas passes through the heat exchanger, the temperature of the flue gas drops to 650°C, and then the flue gas passes through the quenching tower, and the qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com