Draft cooling tower ventilation adjusting system

A technology for ventilation regulation and mechanical cooling, which is applied in water shower coolers, high-efficiency regulation technology, heat exchange equipment, etc. The effect of water separation and removal, stabilizing cooling water temperature, and improving operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

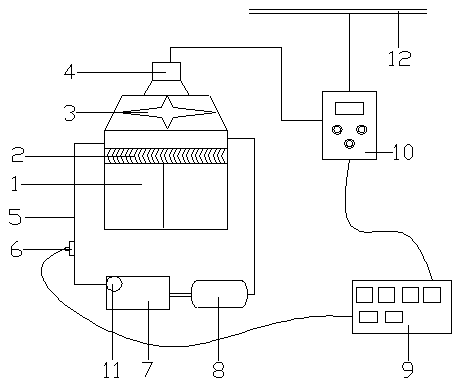

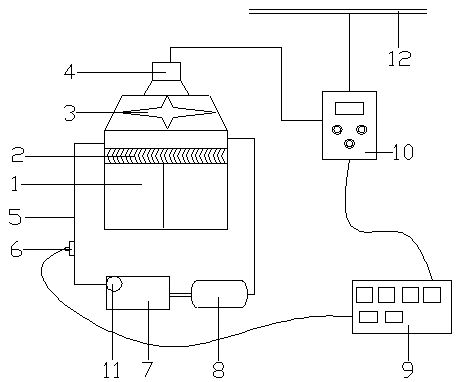

[0016] like figure 1 As shown, a mechanical cooling tower ventilation adjustment system includes a cooling tower 1 and a water receiver 2 with a convective angle waveform structure installed in the cooling tower 1. A fan 3 is installed on the top of the cooling tower 1. The fan 3 is equipped with a rotating speed The motor 4 is 0-1480r / min, the water outlet of cooling tower 1 is connected with circulating water pipe 5, temperature detector 6 is installed on this circulating water pipe 5, and its end is connected with water pump 11, and is connected with reservoir 7; 7 is connected with a condenser 8, which is connected to the upper water inlet of the cooling tower 1 through a return pipe; the temperature detector 6 is connected with a PLC controller 9 through a wire, and the PLC controller 9 is connected with a frequency range through a control line It is a frequency converter 10 of 0-50 Hz; the frequency converter 10 is connected with the motor 4 and connected with a 380V pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com