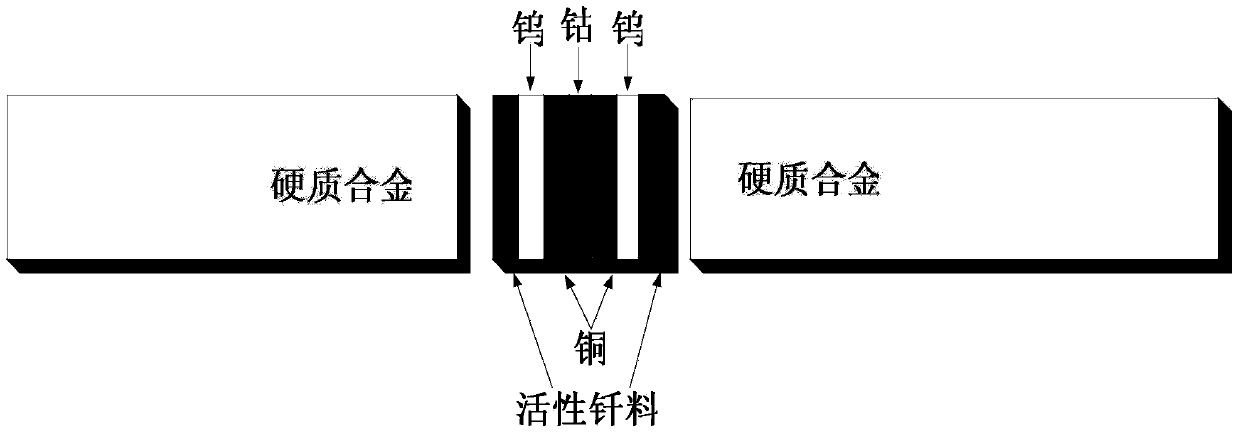

Method for preparing sandwich type composite brazing filler metal for hard alloy brazing

A technology of cemented carbide and composite solder, which is applied in welding equipment, metal processing equipment, welding/cutting media/materials, etc., can solve the problems of large residual stress in joints, high production costs, and low weld strength, and achieve production The effect of high efficiency, improved performance, and improved weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] Specific embodiment one: the preparation method of the sandwich sandwich type composite filler material for cemented carbide brazing in this embodiment is realized according to the following steps:

[0025] 1. Surface pretreatment: Use water sandpaper and metallographic sandpaper to grind the surface of tungsten sheet, cobalt sheet and copper sheet step by step in order from coarse to fine to remove oxide film, then wash with alkali for 5-10 minutes, and rinse with water , then pickled for 5-10 minutes, rinsed with water, then ultrasonically cleaned in acetone for 10-30 minutes, and dried with hot air for later use;

[0026] 2. Cleaning of active solder: take an active solder foil with a thickness of 0.1-0.5 mm to polish the surface to remove the oxide film, then place it in acetone for ultrasonic cleaning for 10-30 minutes, clean it with deionized water, and dry it for later use;

[0027] 3. Card loading: the tungsten sheet, cobalt sheet, copper sheet and active solder...

specific Embodiment approach 2

[0032] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, wash with alkali for 8 minutes, rinse with water, then pickle for 8 minutes, rinse with water, and then ultrasonically clean in acetone for 20 minutes. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step one, the NaOH solution with a mass concentration of 5% to 30% at room temperature is used for alkali washing; the mass concentration of 5% to 50% is used for pickling HNO 3 solution. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com