Preparation method of sandalwood essential oil microcapsules

A technology of sandalwood essential oil and microcapsules, which is applied in the field of preparation of sandalwood essential oil microcapsules, can solve the problems of expensive raw materials, large particle size, and high equipment requirements, and achieve improved slow-release performance, increased stability, and good solubility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

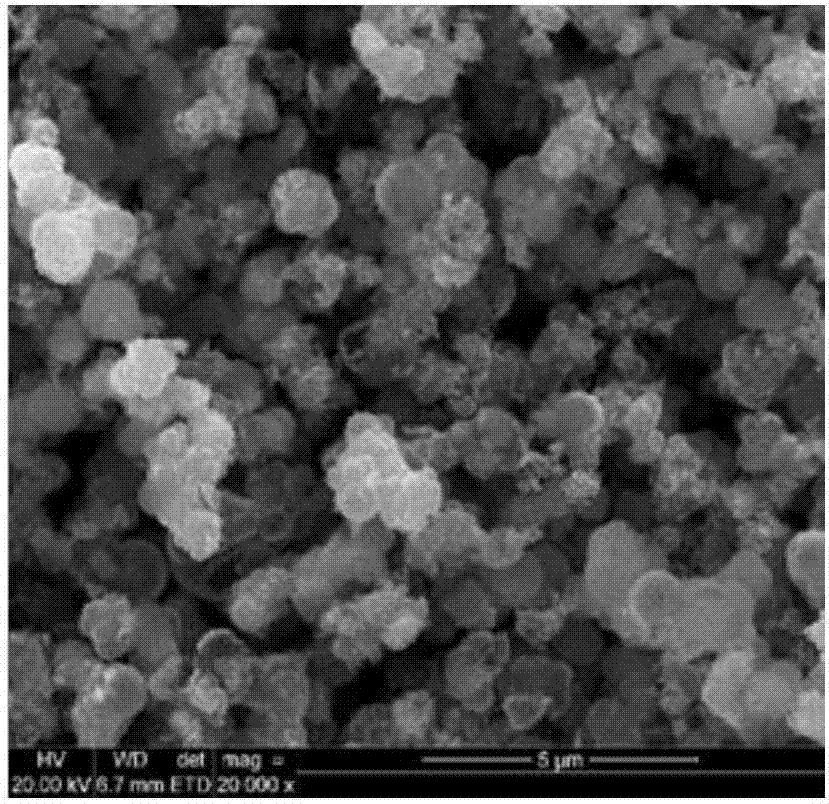

[0030] Embodiment 1: the preparation of sandalwood essential oil microcapsule

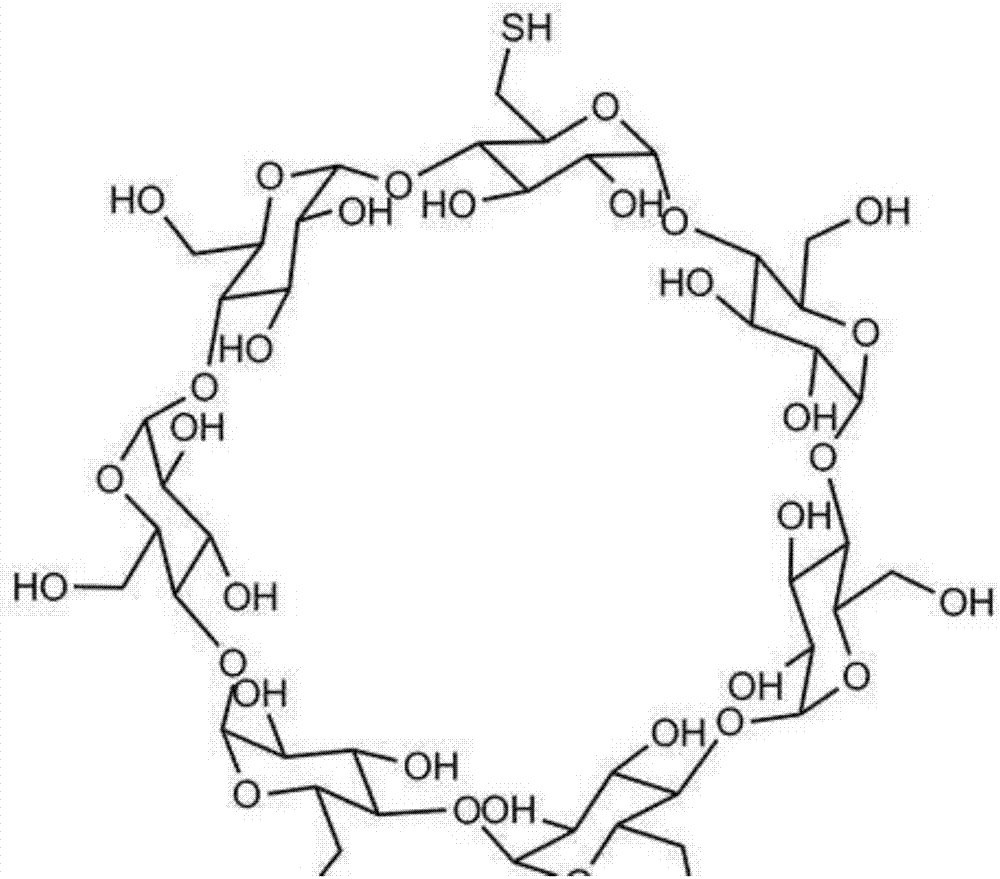

[0031] Sandalwood essential oil microcapsules were prepared by controlling the ratio of sandalwood essential oil and β-cyclodextrin, and the properties of the target microcapsules were studied.

[0032] Get a certain amount of ethanol solution (10%), take 1g sandalwood essential oil as a benchmark, prepare the essential oil solution that mass concentration is 5%, 10%, 15%, 20%. Weigh quantitative β-cyclodextrin and dissolve it in aqueous ethanol (ethanol / water=1 / 2, Volume ratio). Then the essential oil solution is slowly added dropwise to the β-cyclodextrin solution, so that the mass ratio of sandalwood essential oil to β-cyclodextrin is 4, 1, 1 / 2, 1 / 4, 1 / 6, 1 / 8, 1 / 10, 1 / 12, 1 / 14, 1 / 16, 1 / 18, 1 / 20, keep at 55°C and stir during the addition process, after the dropwise addition is completed, turn off the heating, cover and stir for a certain period of time Stand overnight at 4°C, then filter and r...

Embodiment 2

[0033] Embodiment 2: Determination of volatile oil content in sandalwood essential oil microcapsules

[0034] The oil content of sandalwood essential oil β-cyclodextrin inclusion complex is one of the indicators reflecting the inclusion effect, which reflects the proportion of the core material (ie sandalwood essential oil) in the inclusion compound, that is, sandalwood essential oil Effect of β-cyclodextrin inclusion complex on oil loading of sandalwood essential oil. Accurately weigh 1.50 g of sandalwood essential oil microcapsules prepared in Example 1, place in a conical flask, heat on a heating mantle (the temperature of the heating mantle is 220° C.), weigh and record the quality every half an hour, until the quality remains constant Unchanged, combined with the obtained blank rate, the content of sandalwood essential oil in the sample can be obtained. In order to obtain a more accurate oil content, add a group of blank tests, obtain the weight loss quality of the blank...

Embodiment 3

[0037] Embodiment 3: Research on the sustained release performance of sandalwood essential oil microcapsules

[0038]In this experiment, 37°C was selected as the research temperature, and the change law of the remaining mass of untreated essential oil and essential oil microcapsules was measured every hour to study the influence of microcapsules on the stability of essential oil. The volatilization curve of untreated essential oil and essential oil microcapsules with time is as follows: Figure 4 shown.

[0039] Depend on Figure 4 It can be seen that at 37 ° C, the volatilization of untreated sandalwood essential oil and essential oil microcapsules will increase linearly and slowly with time in the initial stage, and the volatilization of sandalwood essential oil microcapsules tends to a balanced state after 10 hours. On the whole, after placing the same time, the volatilization of sandalwood essential oil microcapsules is significantly lower than that of untreated sandalwo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com