Vacuum glass with photoelectric conversion layer

A technology of photoelectric conversion and vacuum glass, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as photoelectric conversion function problems, achieve the effects of reduced oxidation and damage, good heat insulation, and increased thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

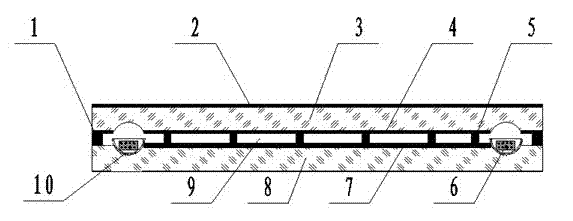

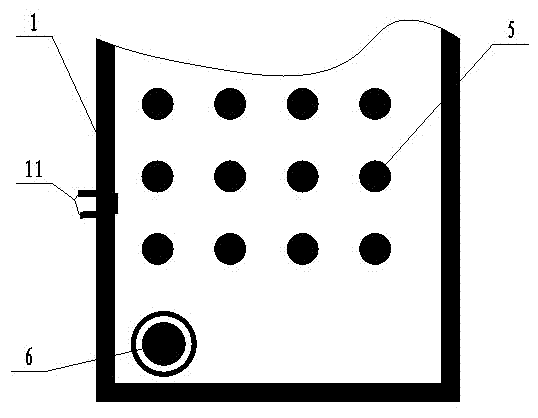

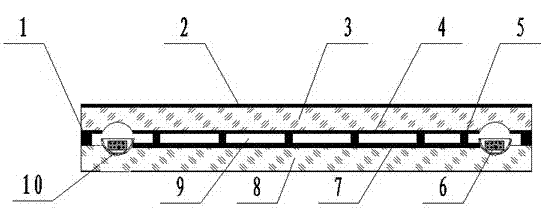

[0022] In order to express the present invention more clearly, the present invention will be further described in conjunction with the accompanying drawings.

[0023] Such as figure 1 and figure 2 As shown, the vacuum glass with a photoelectric conversion layer provided by the present invention mainly includes an upper glass plate 3, a lower glass plate 8, a support column 5, a sealing solder 1, a photoelectric conversion layer 7, a getter 6, and the like. In the vacuum chamber of the vacuum glass, the surface of the lower glass plate 6 on one side is coated with a photoelectric conversion layer 7. The material of the photoelectric conversion layer can be selected according to the needs. On both sides of the photoelectric conversion layer, there are wires connected to the vacuum sealing flux to set a fixed electrode 11. The lower glass plate 6 whose surface is coated with the photoelectric conversion layer 7 is made of non-light-transmitting materials such as ceramics and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com