Carbon-coated aluminum material, and method for production thereof

A technology of carbon coating and aluminum materials, applied in the direction of electrode manufacturing, chemical instruments and methods, and plating of superimposed layers, can solve the problems of internal resistance increase, surface conductivity decrease, and insulation, etc., to maintain adhesion , increase the amount of production, improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

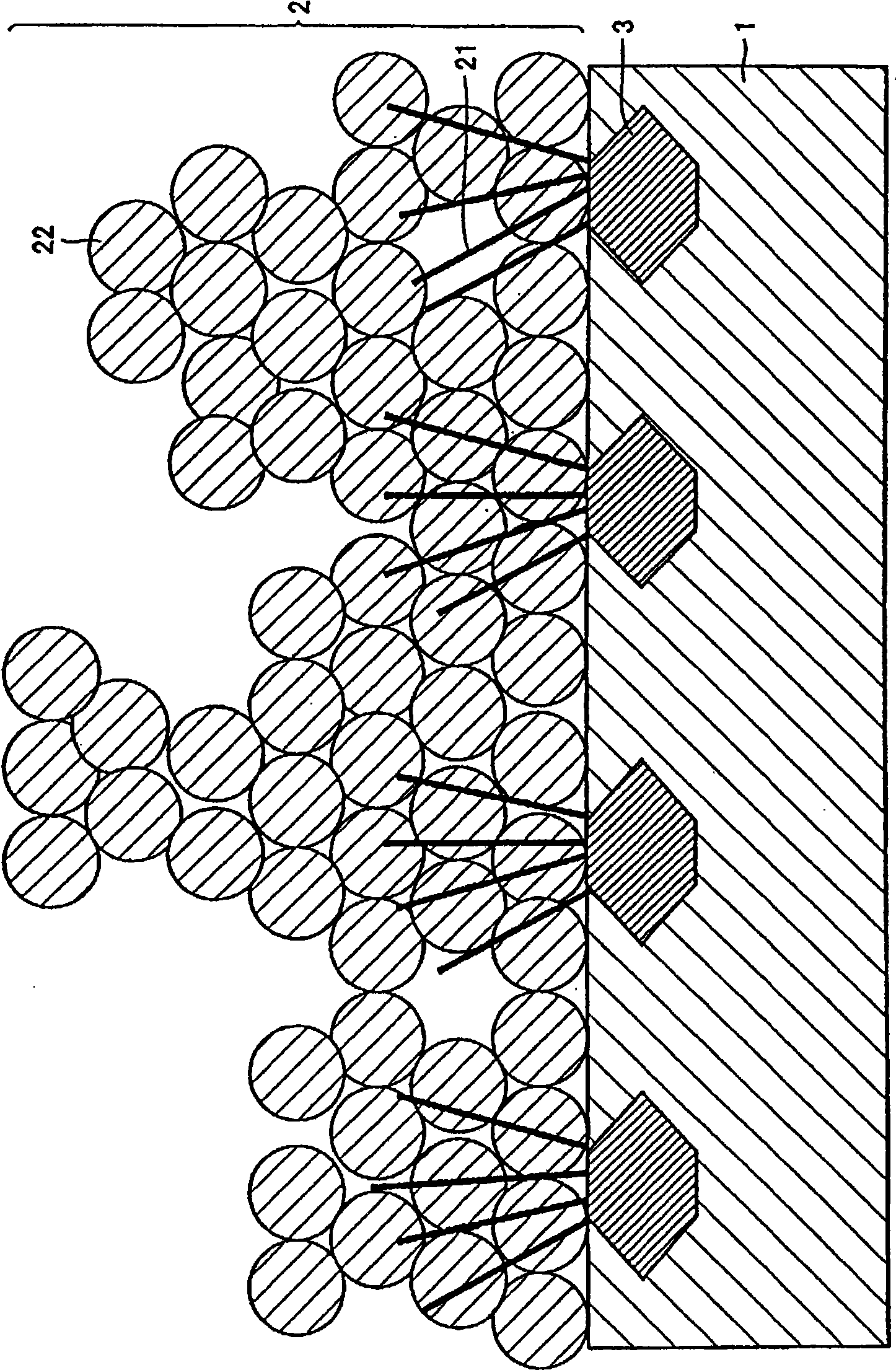

Method used

Image

Examples

example 1

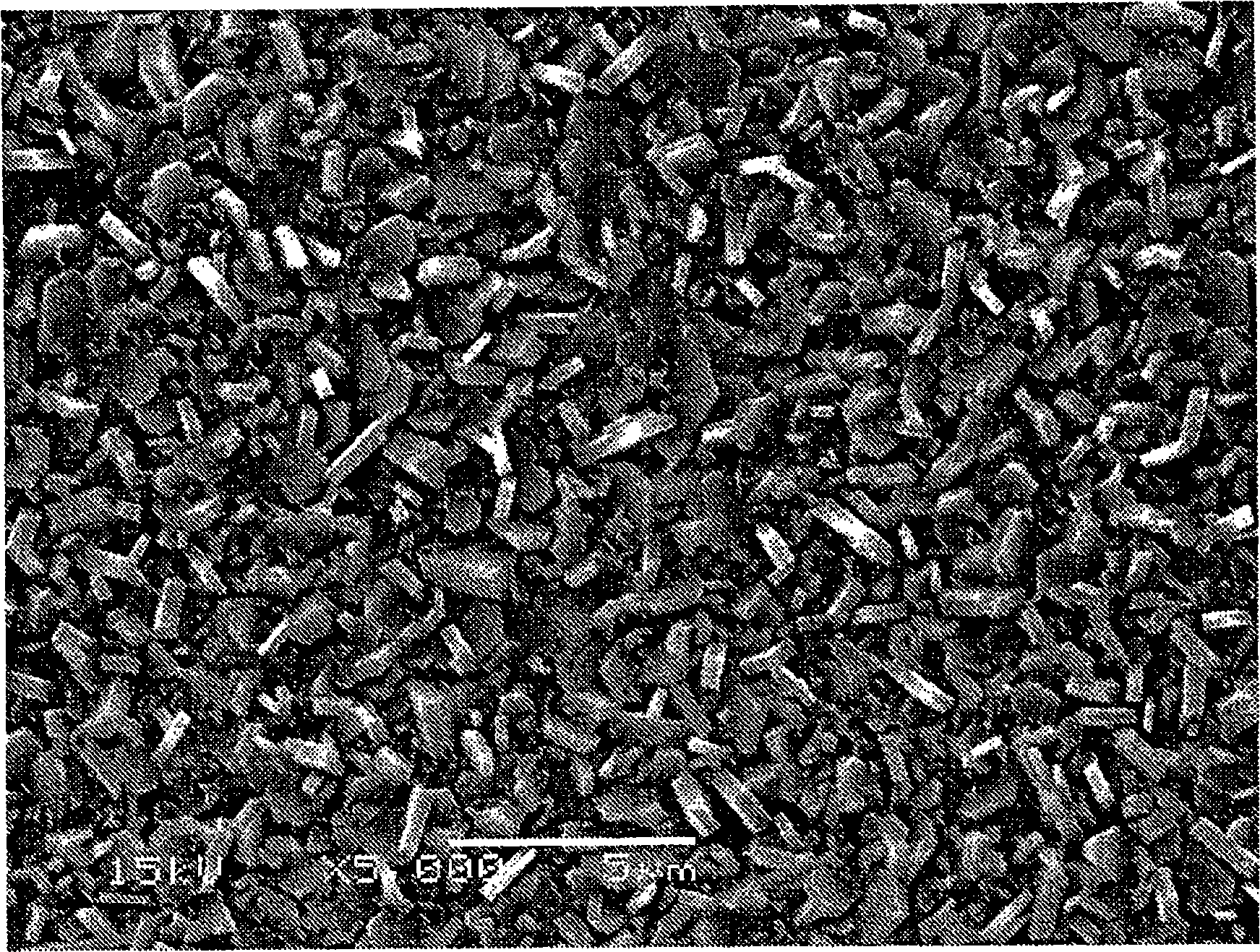

[0083] A carbonaceous substance was coated on both sides of an aluminum foil (JIS A-1050) having a thickness of 50 μm and a composition shown in Table 1, and was dried at 100° C. for 10 minutes to attach the carbonaceous substance. The composition of the carbonaceous material was such that 1 part by weight of butanol was added to 1 part by weight of carbon black (#50 manufactured by Mitsubishi Chemical Corporation) with an average particle diameter of 30 nm. In addition, the adhesion of the carbonaceous substance at this time was adjusted so that the thickness after drying was 1 μm per surface. Then, the aluminum foil to which the carbonaceous substance was adhered was kept at a temperature of 550° C. in a methane gas atmosphere for 10 hours to prepare a sample.

[0084] The surface of the obtained sample was observed with a scanning electron microscope (5000 times magnification). The scanning electron microscope photo is as figure 2 shown.

[0085] (existing example 2)

...

Embodiment 1-3、 comparative example 1-3

[0088] Except having used the aluminum foil of the composition shown in Table 1, it carried out similarly to the conventional example 1, and produced the sample.

[0089] The obtained sample surface of Example 2 was observed with a scanning electron microscope (5000 times magnification). The scanning electron microscope photo is as image 3 shown.

[0090] Table 1 shows the adhesion between the carbon-containing layer and the aluminum foil of the carbon-coated aluminum material obtained in Conventional Examples 1-2, Examples 1-3, and Comparative Examples 1-3, the reliability test over time, and the formed aluminum Carbide Al 4 C 3 analysis results. Evaluation conditions are as follows.

[0091] [closeness]

[0092] The adhesiveness was evaluated by the tape method. A rectangular sample with a width of 10 mm and a length of 100 mm was prepared, and an adhesive tape having an adhesive surface of 15 mm in width and 120 mm in length (manufactured by Sumitomo 3M Co., Ltd., t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com