Method for determining head and tail positions and length of mixed cast blank based on continuous molten steel temperature measurement

A technology for mixing billet and molten steel is applied in the field of testing, which can solve problems such as large workload and reduce metal yield, and achieve the effects of improving mixed casting efficiency, improving economic benefits, and improving yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

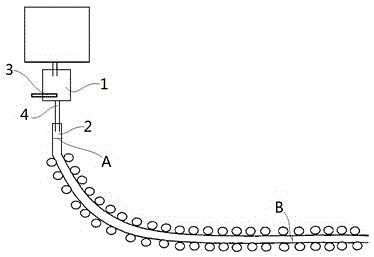

[0019] Example 1: Such as figure 1 As shown, a method for determining the position and length of the head and tail of the mixed billet based on continuous temperature measurement of molten steel takes the following steps:

[0020] When mixing Q345 and IF steel, the casting temperature of Q345 is 1530°C, the casting temperature of IF steel is 1560°C, and the casting speed is 1.2m / min.

[0021] 1) At the end of Q345 steel casting, when the remaining molten steel in tundish 1 is 10% of the total, the nozzle is closed, the continuous casting machine is stopped, and tundish 1 is raised, so that the submerged nozzle is exposed 60mm above the billet shell;

[0022] 2) Add molten steel splitting agent into the crystallizer 2, the molten steel splitting agent is composed of iron powder and rolled steel sheet, and the mass percentage of the composition of the molten steel splitting agent is: iron powder: 100%, rolled steel sheet: 0%, and the average particle size of iron powder and r...

Embodiment 2

[0027] The basic process of a new method of determining the position and length of the head and tail of the mixed cast slab based on the continuous temperature measurement technology of molten steel in this embodiment is the same as that in embodiment 1, except that the continuous temperature measurement device is installed at the upper part of the nozzle 4 of the tundish 200mm, The average particle size of iron powder and rolled steel sheet is: 300-500μm.

[0028] 60Si 2 Mn steel and 45 # Steel, of which 60Si 2 Mn steel casting temperature is 1480℃, 45 # The steel casting temperature is 1530°C.

[0029] A method of determining the position and length of the head and tail of the mixed cast slab based on continuous temperature measurement of molten steel in this embodiment takes the following steps:

[0030] 1) In 60Si 2 At the end of Mn steel casting, when the remaining molten steel in the tundish 1 is 15% of the total amount, close the nozzle, stop the continuous casting...

Embodiment 3

[0036] The basic process of a new method of determining the position and length of the head and tail of the mixed cast slab based on the continuous temperature measurement technology of molten steel in this embodiment is the same as that in embodiment 1, except that the continuous temperature measurement device is installed on the nozzle 4 of the tundish 300mm away.

[0037] 60Si 2 Mn steel and 45 # Steel, of which 60Si 2 Mn steel casting temperature is 1480℃, 45 # The steel casting temperature is 1530°C.

[0038] A method of determining the position and length of the head and tail of the mixed cast slab based on continuous temperature measurement of molten steel in this embodiment takes the following steps:

[0039] 1) In 60Si 2 At the end of Mn steel casting, when the remaining molten steel in the tundish 1 is 20% of the total amount, the nozzle is closed, the continuous casting machine is stopped, and the tundish 1 is raised so that the submerged nozzle is exposed 130mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com