Converter steelmaking technology for directly reducing-alloying manganese ore

A converter steelmaking and alloying technology, applied in the metallurgical industry, can solve the problems of inability to adjust in a large range, affect the dephosphorization effect, and reduce the yield of manganese, and achieve the effects of reducing the degree of fluorine pollution, reducing pollution and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

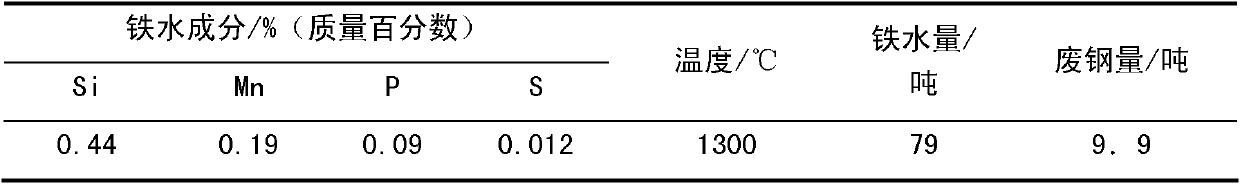

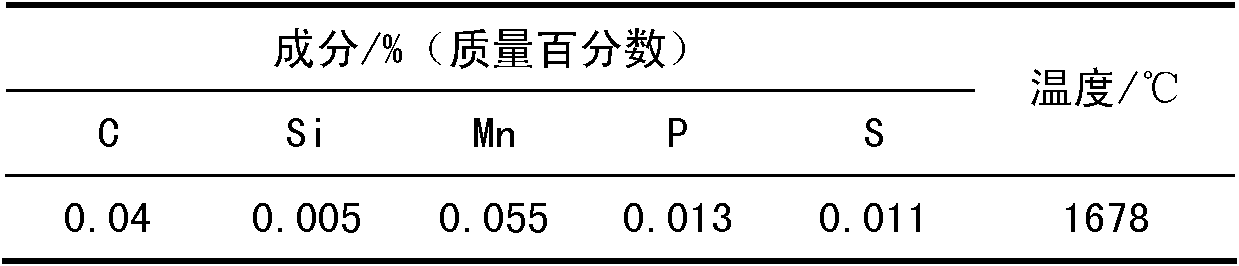

[0026] The converter double slag method steelmaking process (80 tons of converter) of the present invention adopts the direct reduction alloying of manganese ore to smelt the Q235B steel grade, and the specific molten iron conditions, technological processes and terminal conditions in Examples 1, 2 and 3 are as shown in Tables 4-7. Show.

[0027] Table 4 Molten Iron and Steel Scrap

[0028]

[0029] Table 5 Main components of manganese ore

[0030]

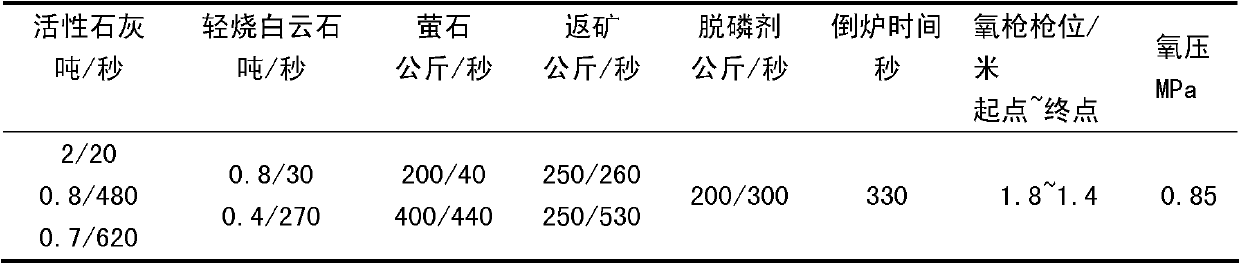

[0031] Table 6 Smelting process data

[0032]

[0033] Process method: see Table 6, pour molten iron into the converter, add steel scrap (111-91 kg / ton molten iron); control the oxygen lance (the height of the starting point of the oxygen lance is 2.2-2.0 meters, and the height of the end point is 1.4 meters) and oxygen pressure (0.8-0.85MPa before the furnace is turned down, and 0.85MPa after the furnace is turned down) Perform soft blowing operation at high gun position, add the first batch of slag (including dephosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com