Method for producing white spirit by utilizing waste spent grains

A liquor and waste disposal technology, which is applied in the field of wine making, can solve the problems of wasting resources, environmental pollution, and high recycling costs, and achieve the effects of improving liquor yield, broad application prospects, and reducing grain consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

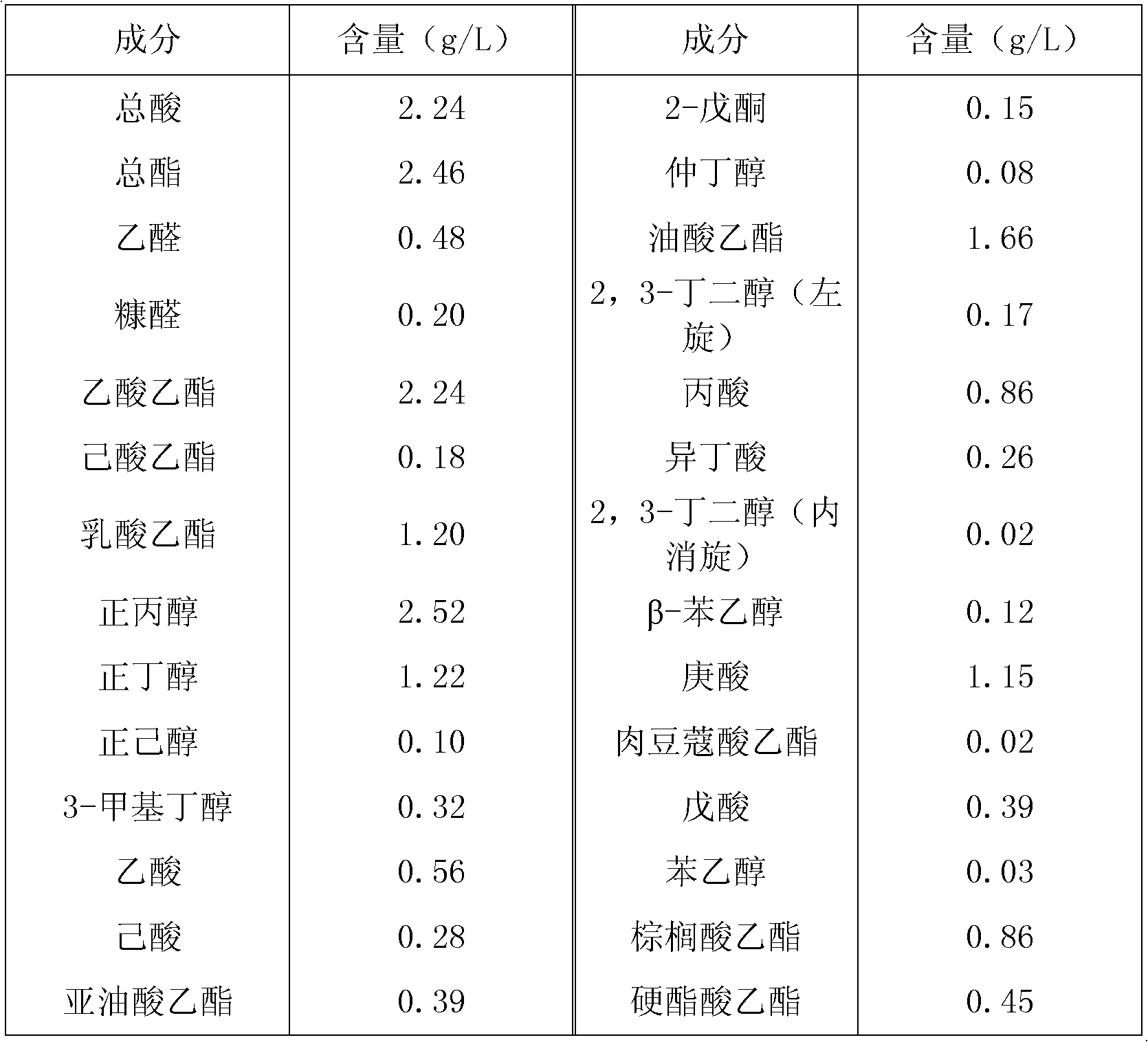

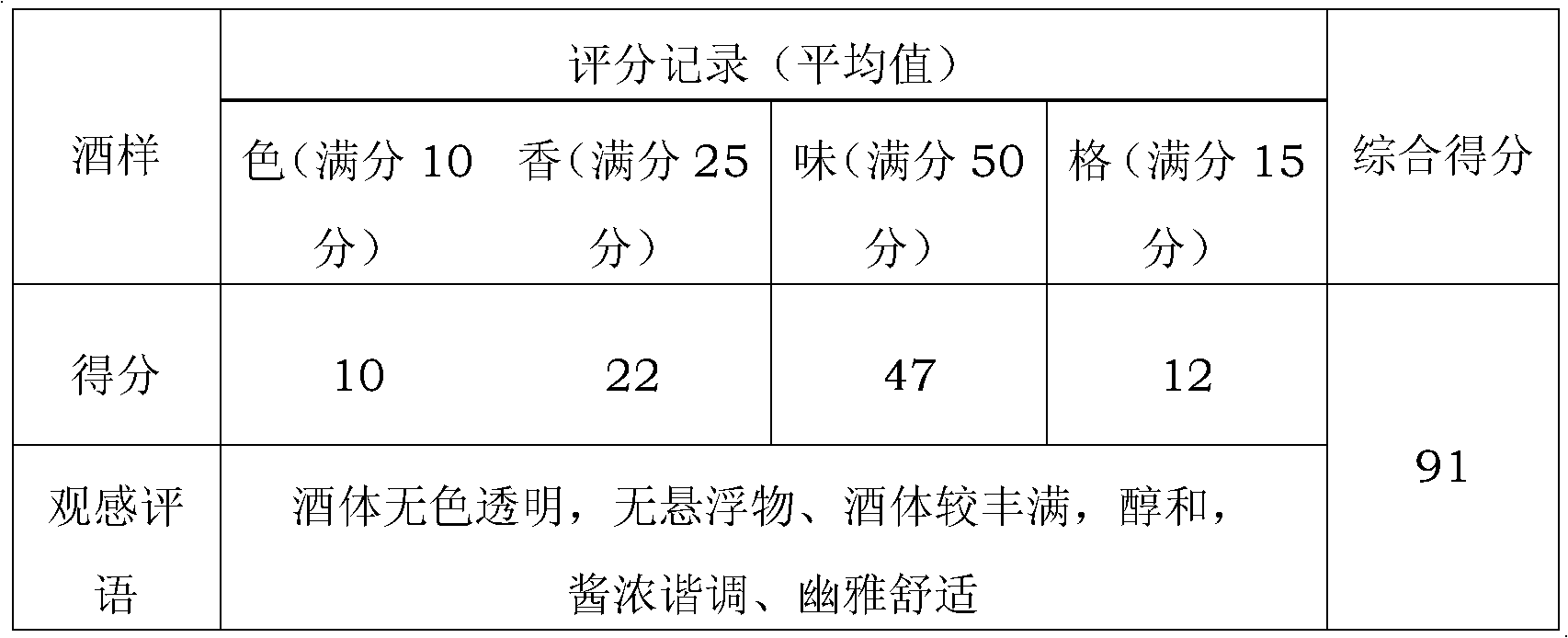

[0030] Example 1 adopts the inventive method to produce liquor

[0031] Spread out 8000kg of grains from the retort and let it cool down to 35°C, then start to sprinkle high-temperature Daqu, the amount of koji used is 400kg, mix evenly, so that the waste is evenly adhered to high-temperature Daqu powder, and control the stacking temperature at 28°C to 32°C . The piled fermented grains are piled up from the center outward, covering one layer after another, and start to pile up. The diameter of the pile is 4m and the height is 1.4m.

[0032] After the temperature at 20cm from the surface of the heap reaches 55°C, the pile is broken, and the broken grains are spread to cool to 32°C. Before the grains are put into the cellar, the wall of the cellar is sprayed with hot water higher than 85°C, and each layer of the pile is broken. After the unstrained spirits are mixed evenly, they are fermented in a stone wall and mud bottom cellar. After the accumulation of bad grains is finis...

example 2

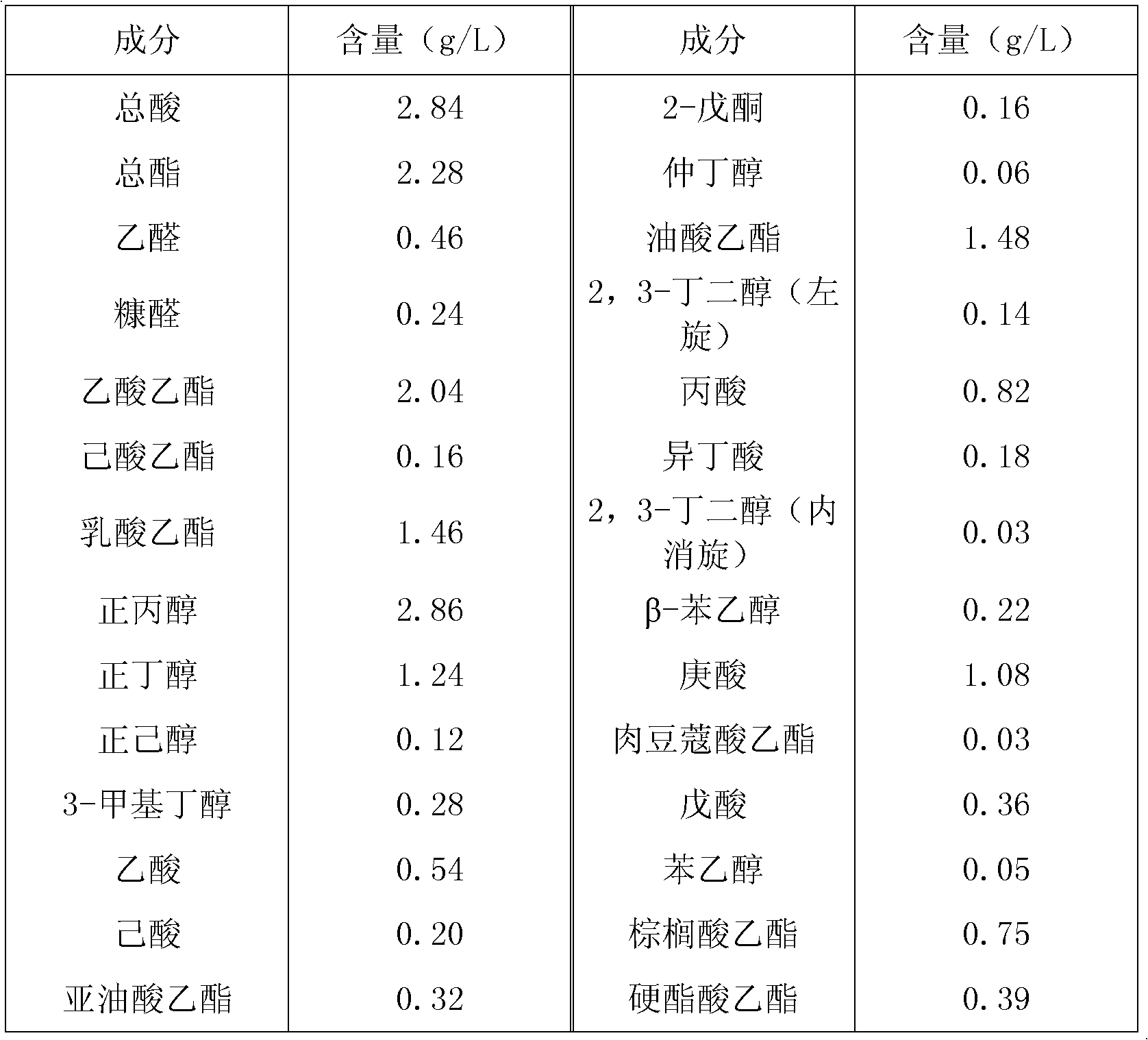

[0039] Example 2 adopts the inventive method to produce liquor

[0040] Spread out 8000kg of grains from the retort and let it cool down to 32°C, then start spreading high-temperature Daqu, the amount of koji used is 100kg, mix evenly, so that the waste is evenly adhered to high-temperature Daqu powder, and control the stacking temperature at 28°C to 32°C . The piled fermented grains are piled up from the center outward, covering one layer after another, and start to pile up. The diameter of the pile is 5m and the height is 1.2m.

[0041]After the temperature at 20cm from the surface of the heap reaches 50°C, the pile is broken, and the broken grains are spread to cool to 25°C. Before the grains are put into the cellar, the wall of the cellar is sprayed with hot water higher than 85°C, and each layer of the pile is broken. After the unstrained spirits are mixed evenly, they are fermented in a stone wall and mud bottom cellar. After the accumulation of bad grains is finished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com