Patents

Literature

39results about How to "Reduce alcohol consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Serotonin transporter gene and treament of alcoholism

ActiveUS20110112159A1Physical improvementImproving psychological sequelaOrganic active ingredientsBiocideDiseaseAlcoholisms

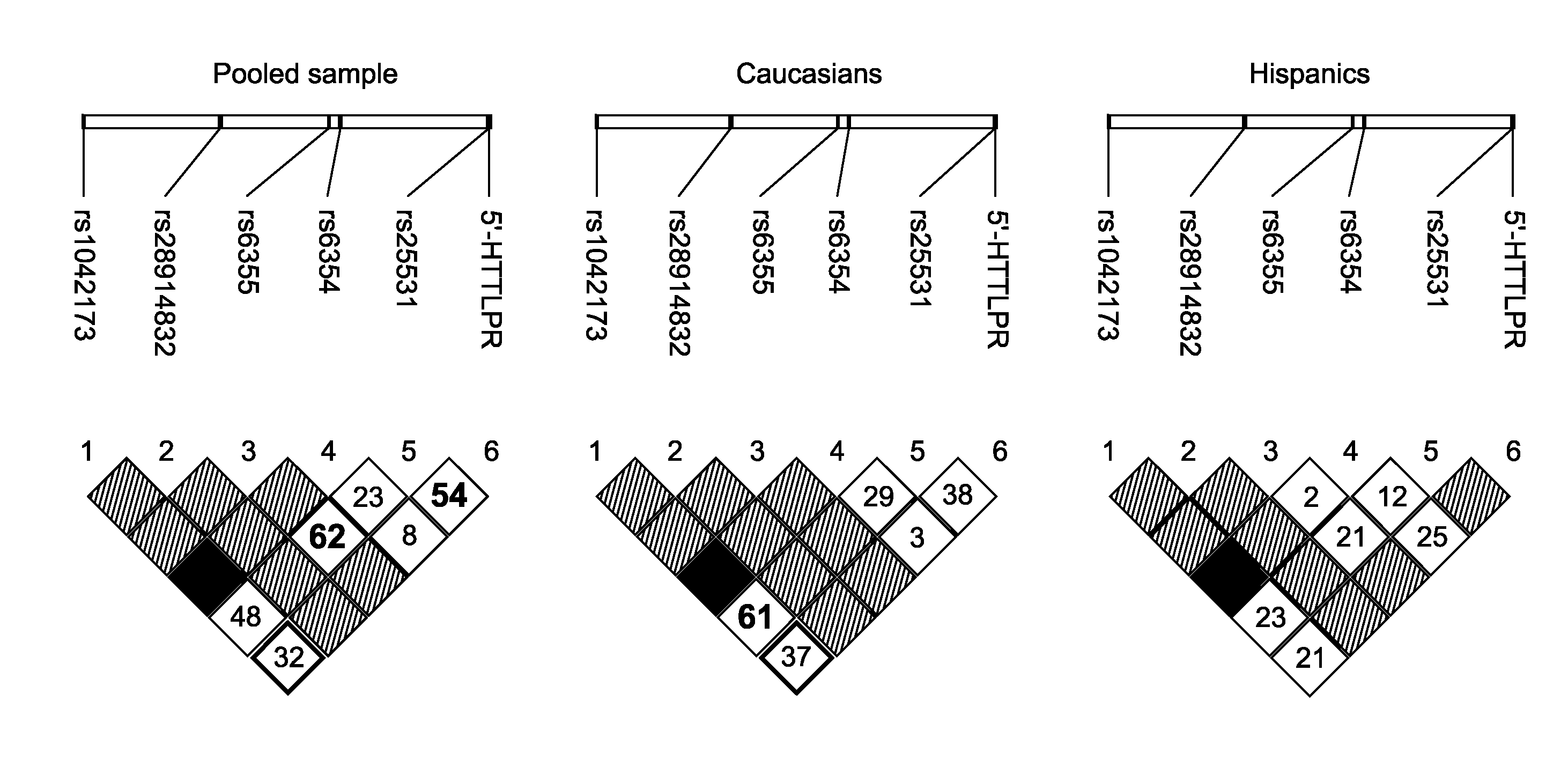

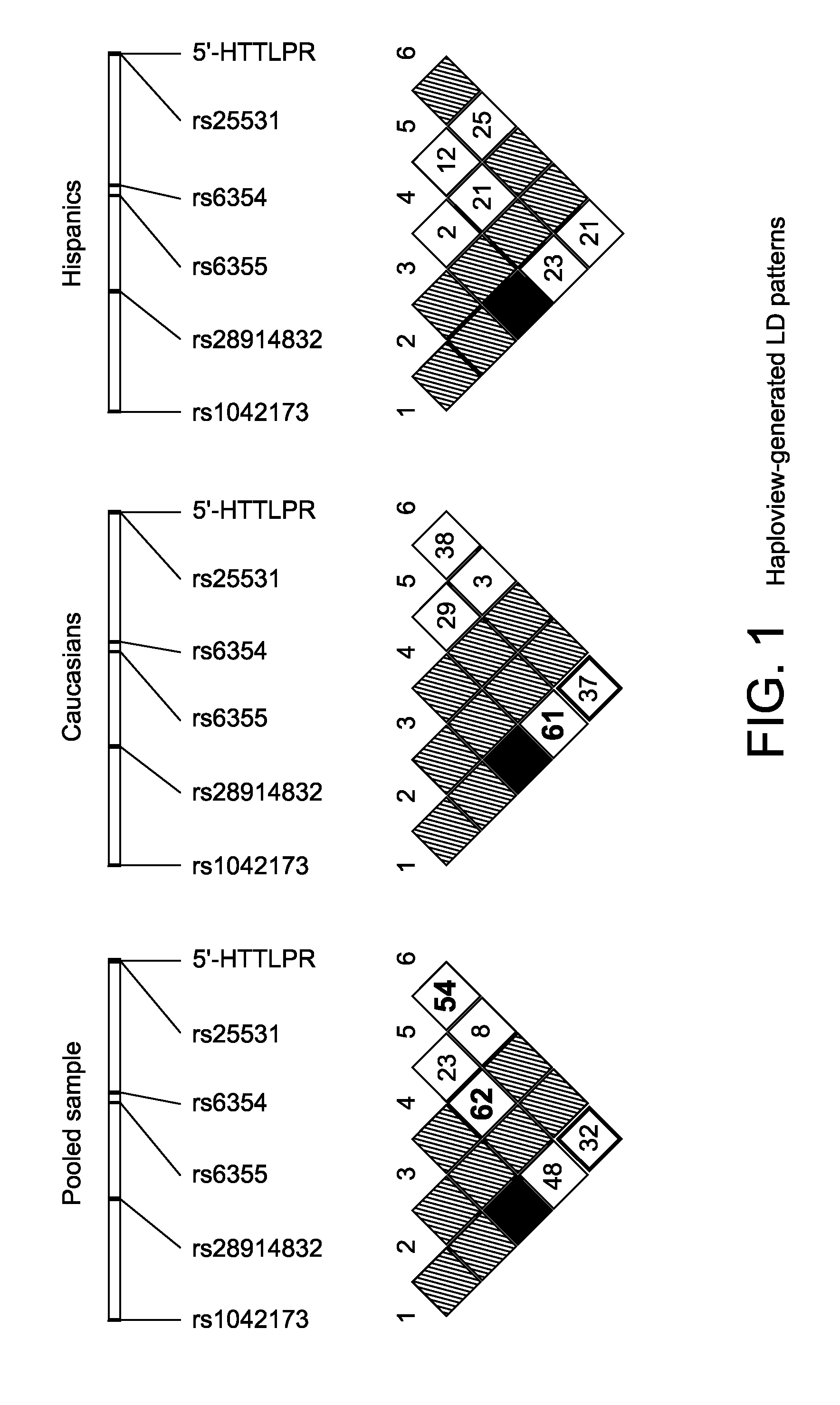

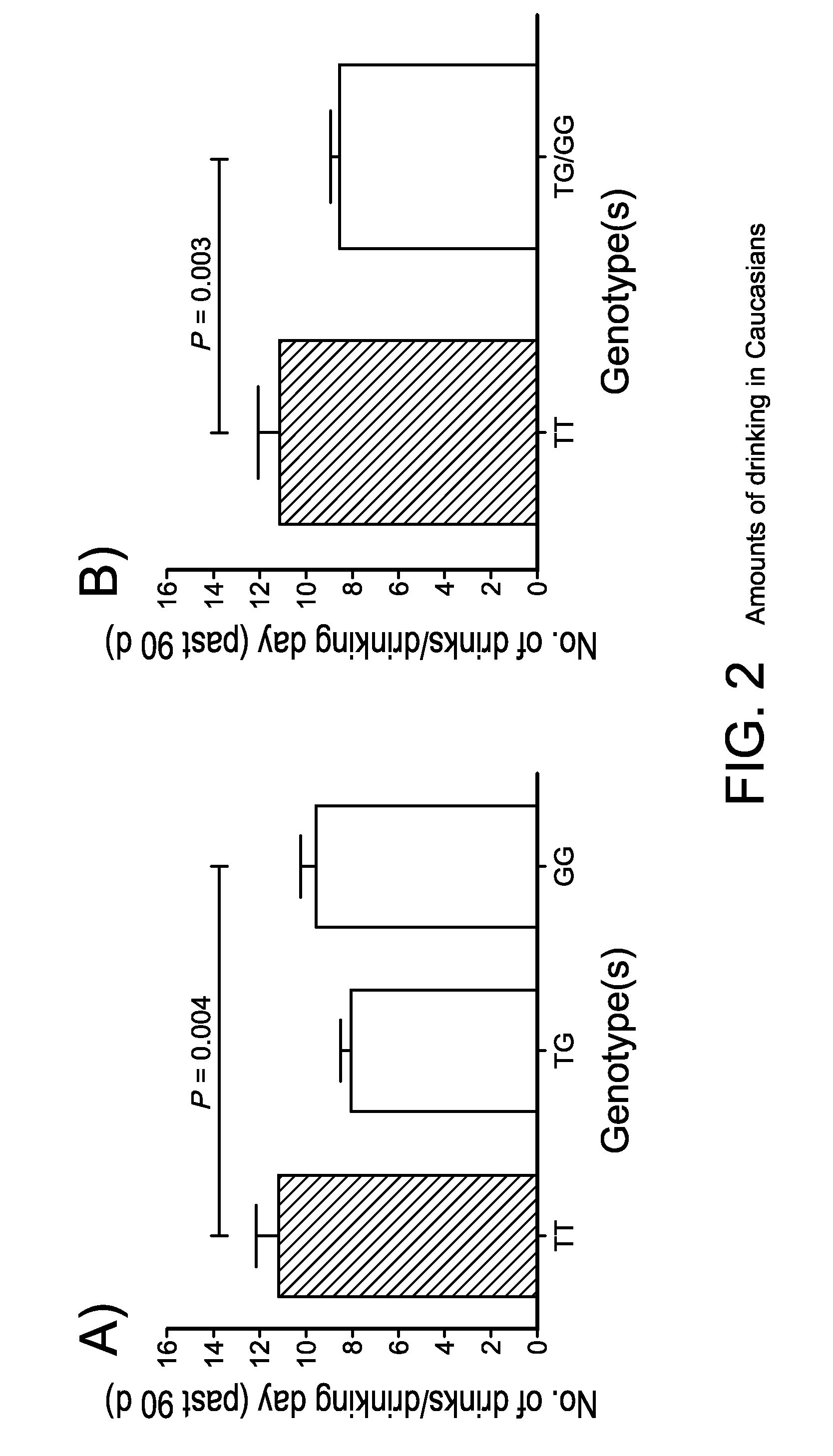

The gene responsible for encoding SERT has a functional polymorphism at the 5′-regulatory promoter region, which results in two forms, long (L) and short (S). The LL-genotype is hypothesized to play a key role in the early onset of alcohol use. The present invention discloses the differences in treatment and diagnosis based on the L or short genotypes as well as on a single nucleotide polymorphism of the SERT gene, the 3′ UTR SNP rs 1042173. The present invention demonstrates the efficacy of using the drug ondansetron and similar drugs for treatment based on variations in the polymorphisms of the SERT gene as well as methods for diagnosing susceptibility to abuse of alcohol and other addiction-related diseases and disorders.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Methods and compositions for the treatment of alcoholism and alcohol dependence

InactiveUS20120282255A1Physical improvementImproving psychological sequelaBiocideNervous disorderAlcoholismsDisease

The present invention provides for compositions and methods for treating or preventing addictive and compulsive diseases and disorders, particular alcohol-related diseases and disorders, disclosed herein. The GLP activators of the present invention are effective against various alcohol and drug dependency diseases. In accordance with the invention, the present compositions and methods can be used to intercede upstream or downstream in the signal transduction cascade involved in GLP action to treat various alcohol and drug dependency diseases. In one embodiment, the synthesis or release of endogenous GLP can be stimulated. In another embodiment, the endogenous synthesis or release of another molecule active in the cascade downstream from GLP, (e.g., a molecule produced in response to GLP binding to a receptor), can be stimulated. Accordingly, the methods and compositions of the invention are useful for preventing, treating, diagnosing, or monitoring the progression various alcohol and drug dependency diseases disclosed herein.

Owner:SUMMIT BIOSCI

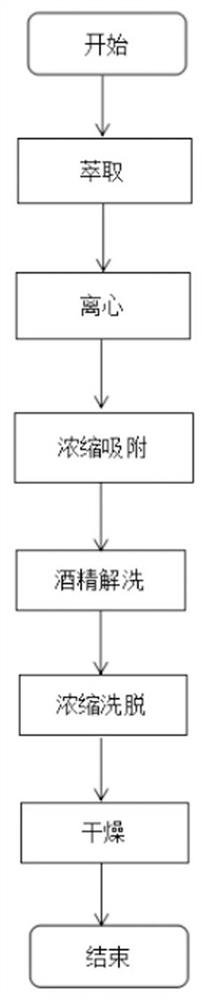

Preparation process of pine bark proanthocyanidin

The invention discloses a manufacturing method to extract pine cyanin, which comprises the following steps: lixiviating, centrifuging, columning; condensing; drying; adopting one pattern of PN700, CAD40, YWD04B1 or YWD09D to adsorb cyanin selectively; washing resin through purified water or deionized water; recycling alcohol through decompressing and distilling; obtaining the dried powder through spraying drying tower.

Owner:浙江瑞康生物技术有限公司

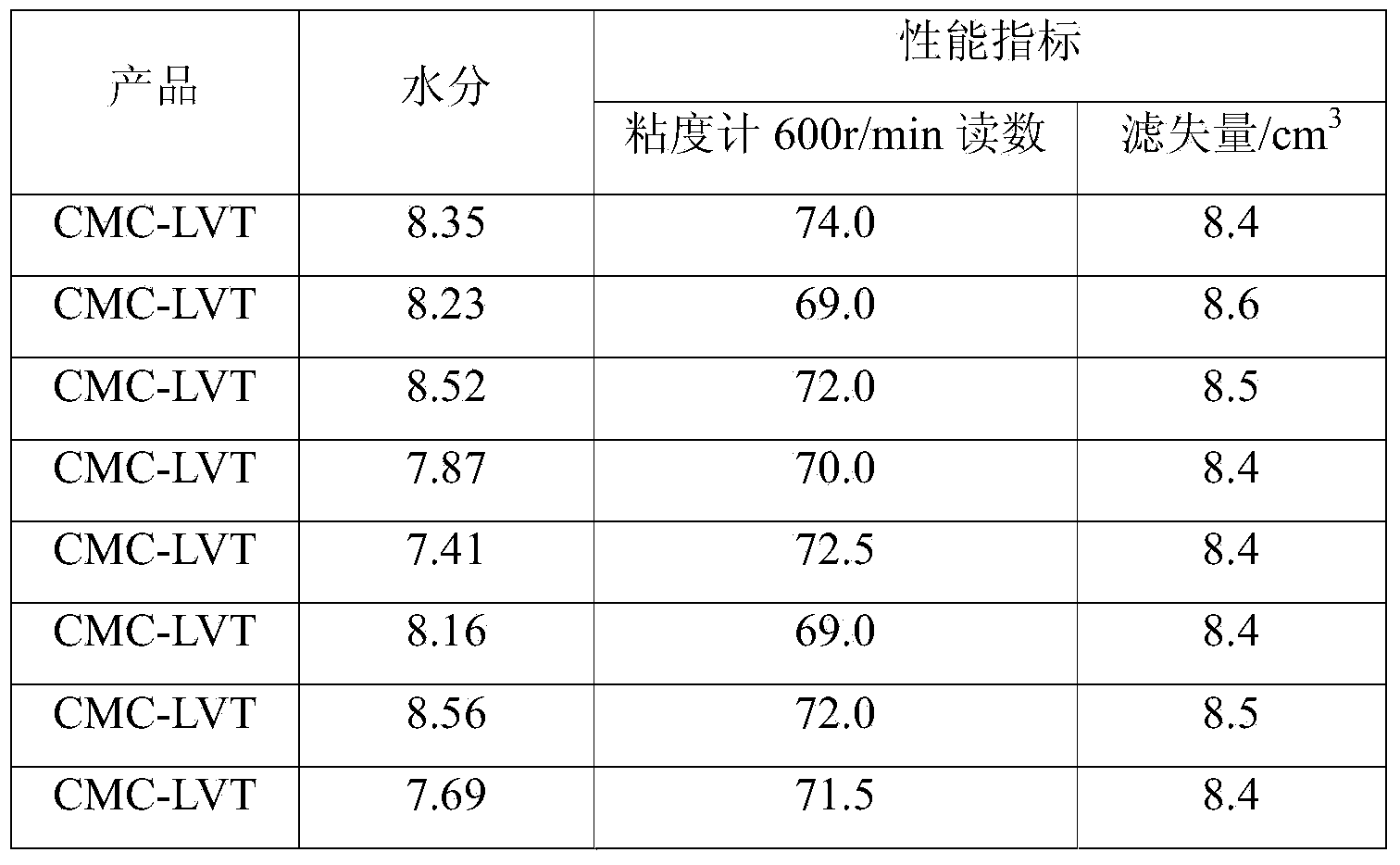

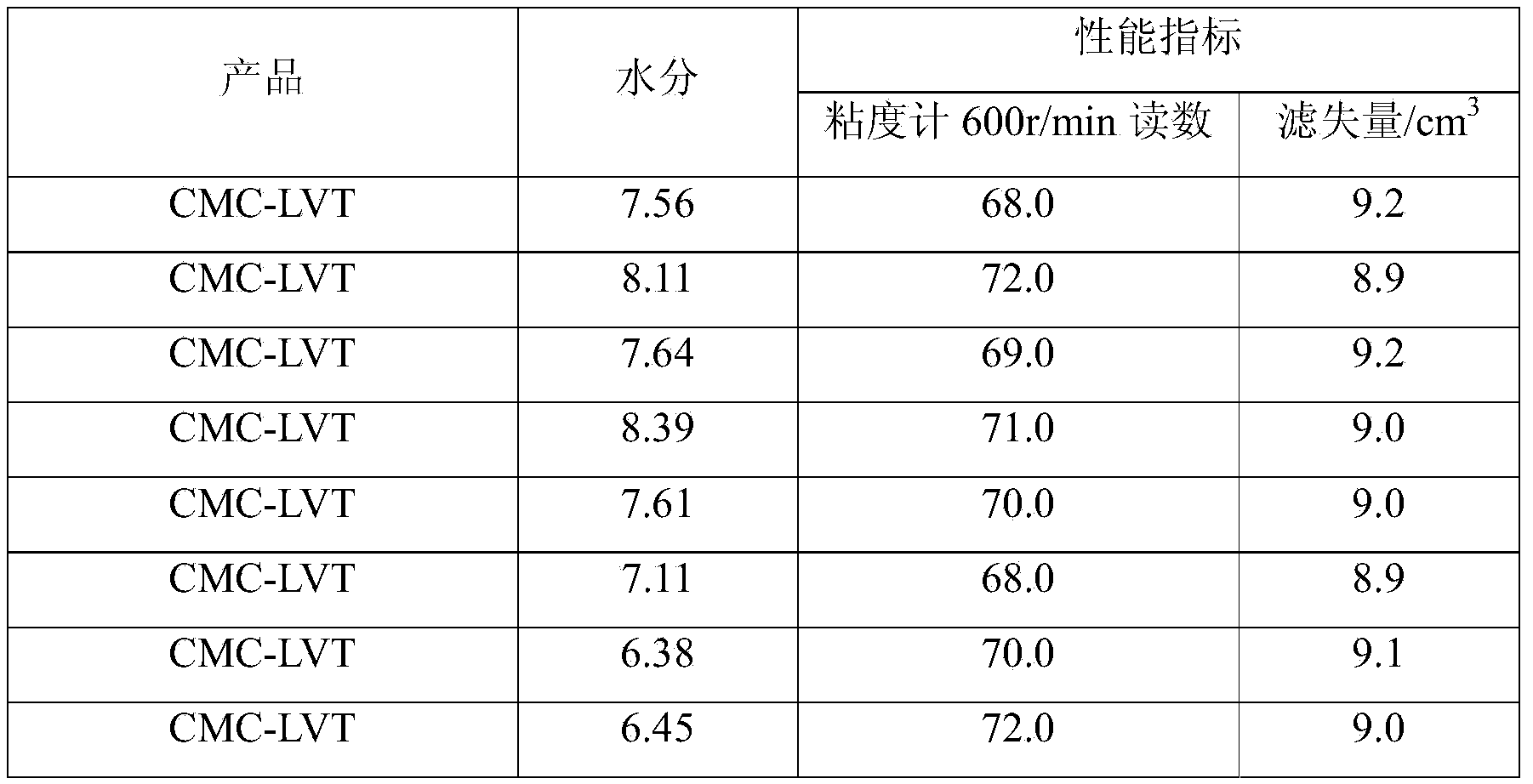

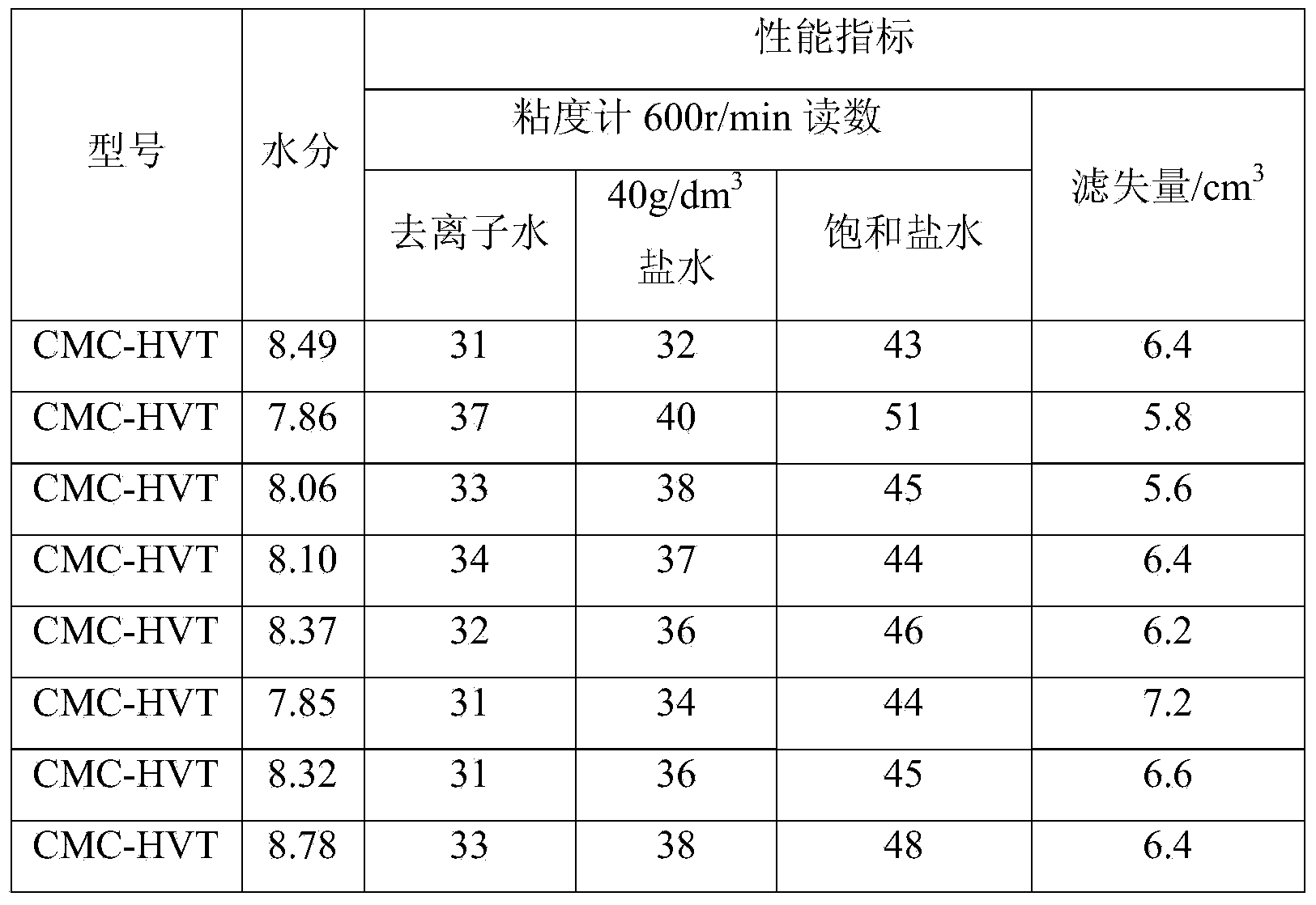

Production method of technical-grade sodium carboxymethylcellulose

The invention belongs to the field of production of sodium carboxymethylcellulose, and specifically relates to a production method of technical-grade sodium carboxymethylcellulose, wherein the method is low in production cost and can be carried out on a solvent method production line. The method comprises the following steps: a, preparation of liquor; b, alkalization reaction; c, acidification and etherification. The purpose of production on the original solvent method production line is realized by adopting a method of increasing the water content of a reaction system and reducing the use level of alcohol of the reaction system by means of adjusting and controlling parameters of the reaction system; the cost of producing technical-grade sodium carboxymethylcellulose [CMC-LVT (Carboxymethylcellulose-Low Viscosity Technical) and CMC-HVT (Carboxymethylcellulose-How Viscosity Technical)] by the original solvent method is lowered.

Owner:泸州北方纤维素有限公司

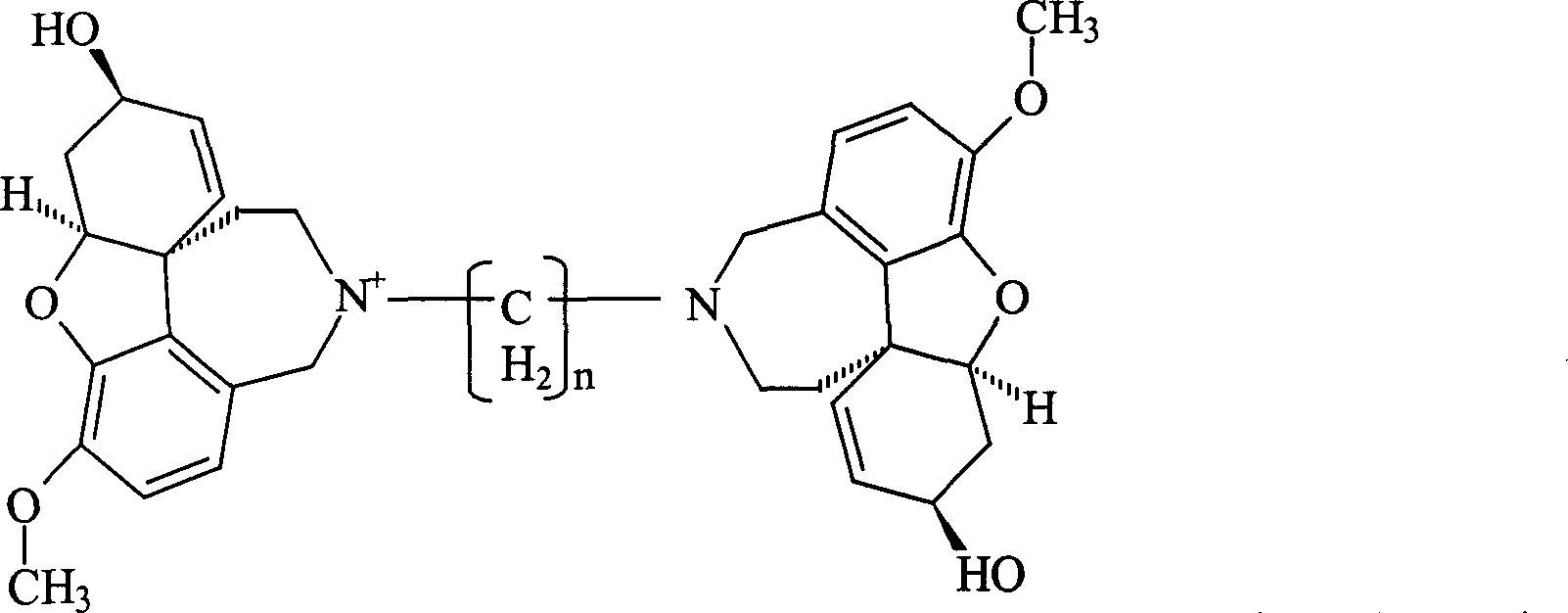

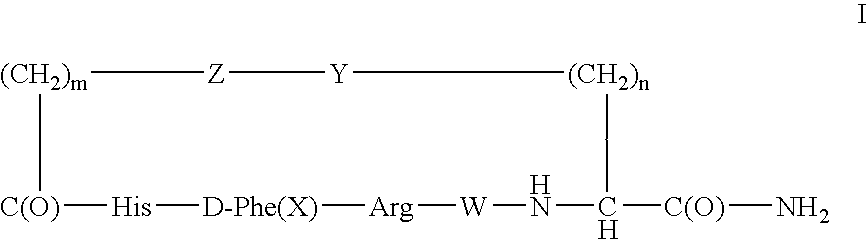

Cyclic peptide melanocortin receptor ligands

InactiveUS20100173834A1Reduce alcohol consumptionWeight increaseMetabolism disorderAntipyreticCyclic peptideStereochemistry

The present invention is directed to compounds according to formula, (R2R3)-A0A1-c(A2-A3-A4-A5-A6-A7-A8-A9)-A10-R1, wherein the definitions of A1 to A10 and R1 to R3 are provided in the application, and pharmaceutically-acceptable salts thereof, that act as ligands for one or more of the melanocortin receptors, to methods of using such compounds to treat mammals, and to pharmaceutical compositions comprising said compounds.

Owner:IPSEN PHARMA SAS +1

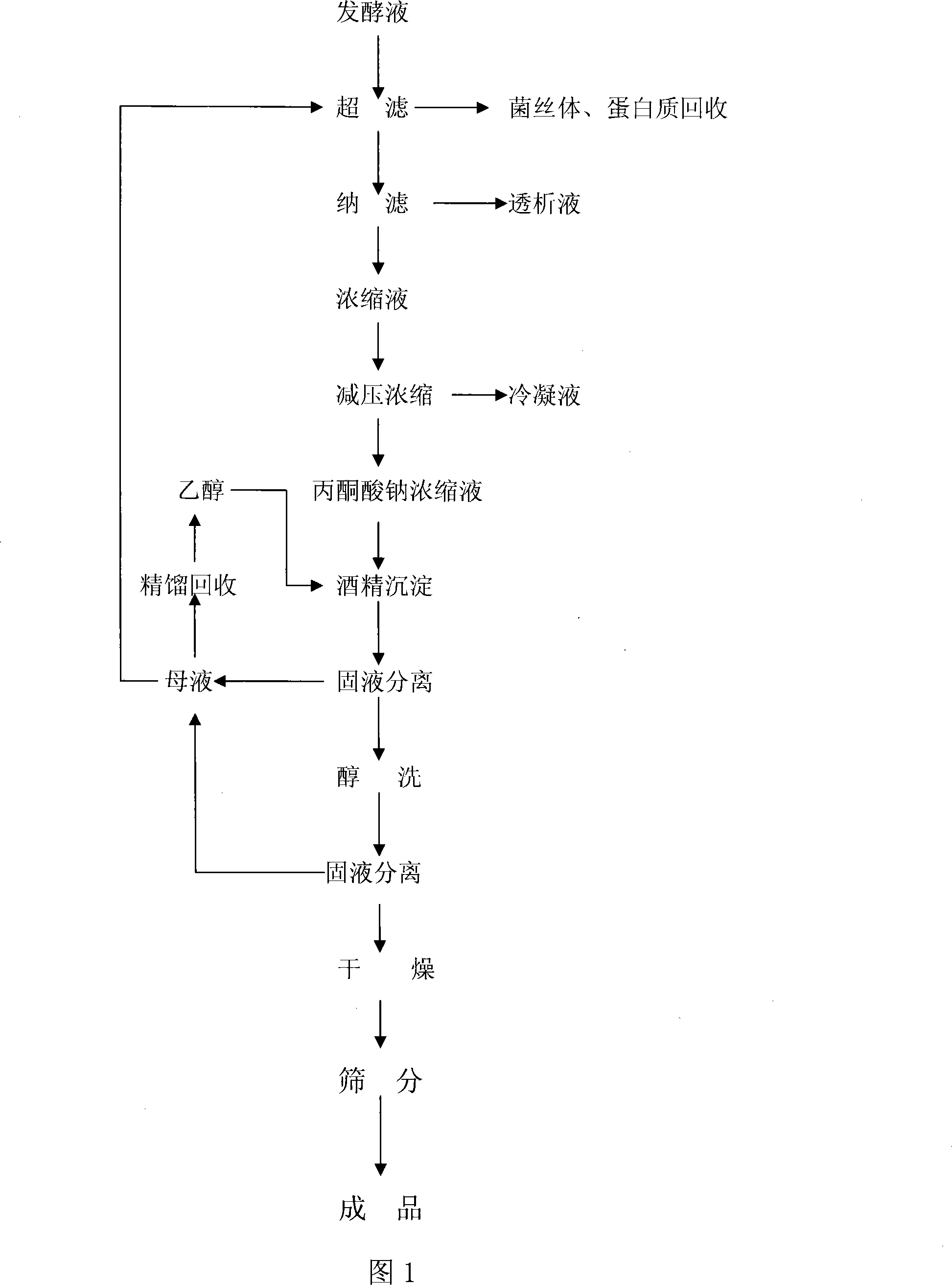

Method for extracting and separating sodium ketopropionate from acetonic acid fermentation liquid by double membrane two-step process

InactiveCN101205181ASimple stepsLow yieldCarboxylic compound separation/purificationEthanol precipitationSodium pyruvate

A method for extracting and separating the sodium pyruvate from the pyruvate fermentation broth by adopting the double membrane two-step process comprises the following steps: 1. the sodium pyruvate concentrated solution is extracted and separated through the double membrane process; 2. the sodium pyruvate concentrated solution is used for preparing the sodium pyruvate solids: the sodium pyruvate concentrated solution goes through the production steps such as the ethanol precipitation, separation of the precipitates from the mother liquors, drying, grinding, screening, inspection, finished product packaging, etc. so as to obtain the qualified sodium pyruvate solids. The invention has the advantages of short production process, high product purity, high utilization ratio, high automation degree, few contamination caused to the environment, low production cost, etc., and is especially suitable for the industrialized large-scale production of the sodium pyruvate.

Owner:NANCHANG UNIV +1

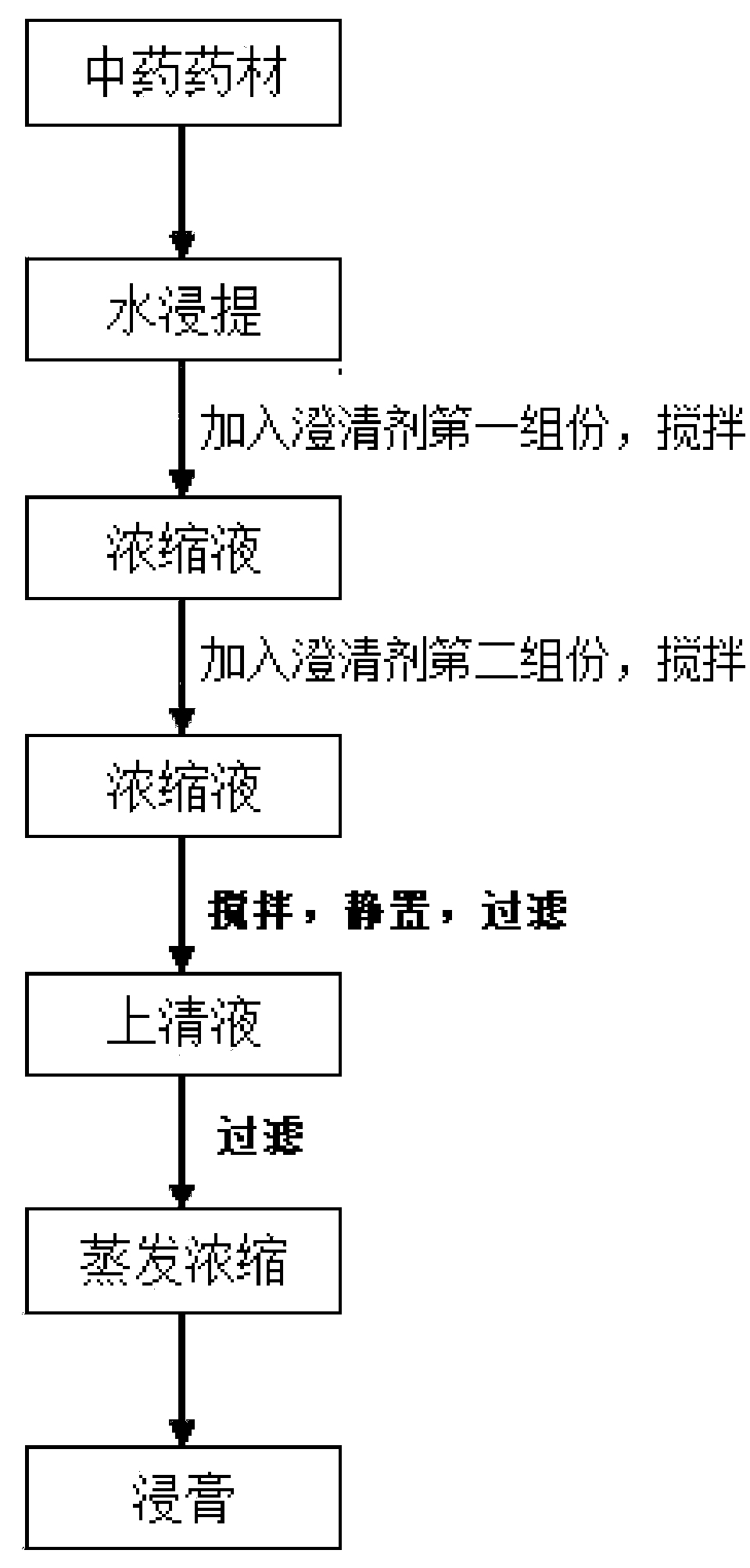

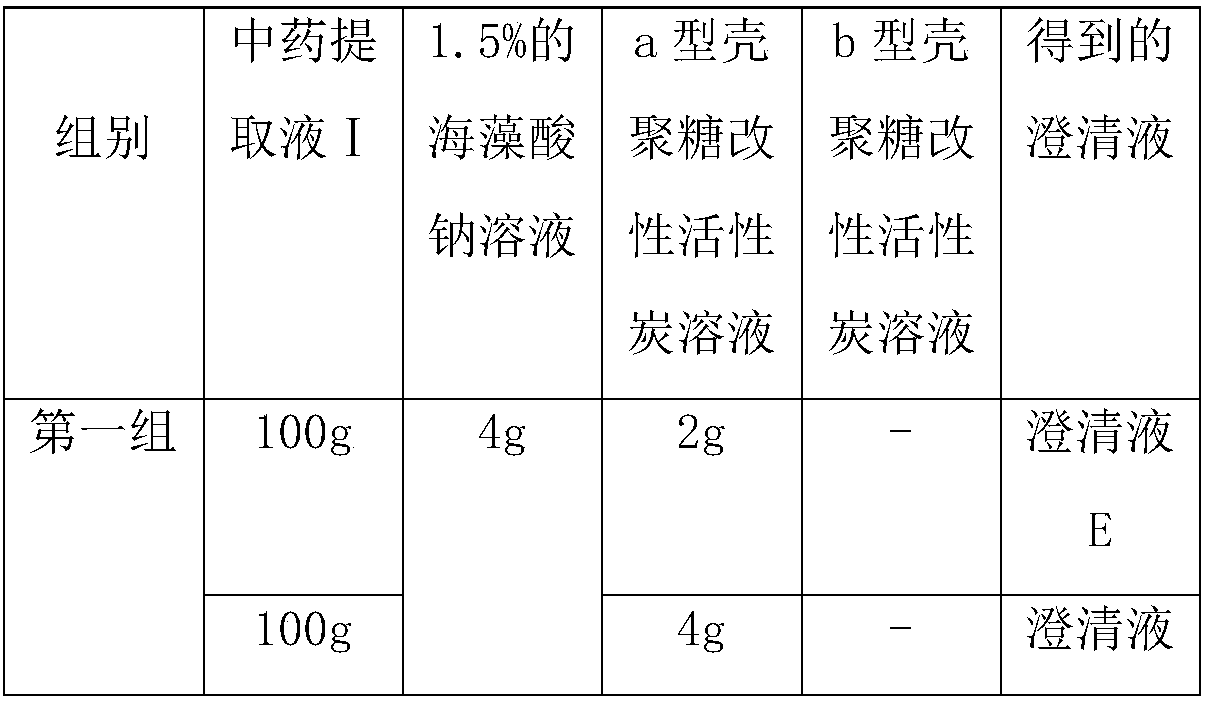

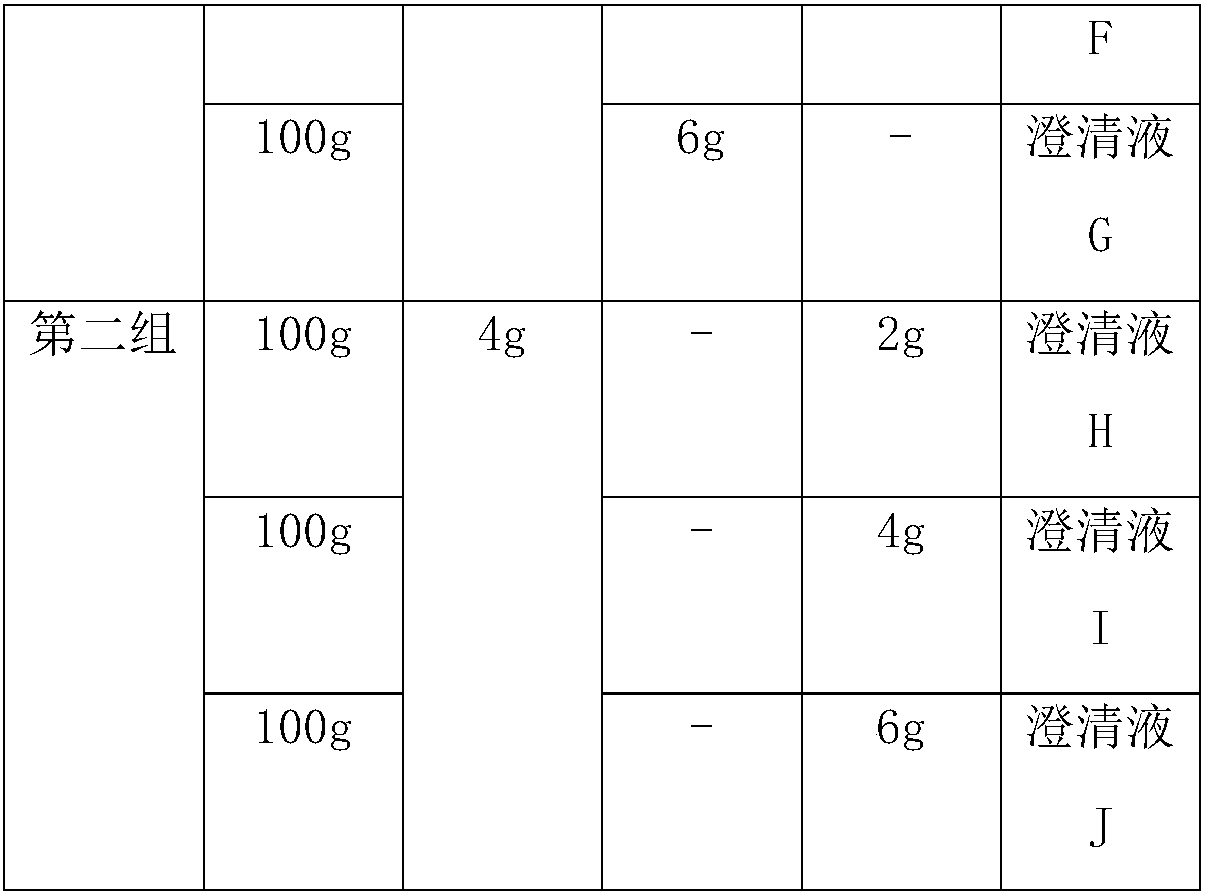

1+1 clarification method

ActiveCN108273291AReduce alcohol consumptionGood adsorption effectSedimentation separationActivated carbonTannin

The invention discloses a 1+1 clarification method. Coarse particles as well as macromolecular impurities such as starch, tannin, phlegmatic temperament and protein in traditional Chinese medicine extracting liquid are adsorbed and removed by utilizing the agglomeration and flocculation effects of a 1+1 clarifying agent, and the stability of a water extract is destroyed, so that the aims of refining and improving the quality of a finished product preparation are fulfilled. The 1+1 clarifying agent comprises a component A and a component B, wherein the component A is a sodium alginate solution;the component B is a chitosan modified activated carbon solution; the adding sequence of the component A and the component B is changed according to the pH value of clarifying liquid; after the firstcomponent is added, bridging connection is conducted among macromolecules with different solubility, the molecules are enlarged rapidly, and the second component performs bridging on the basis of a composite formed by the first component to enable floccules to be formed rapidly on the original basis; due to the use of a chitosan-sodium alginate copolymer, the flocculation effect is enhanced; furthermore, compared with alcohol precipitation, the 1+1 clarification method has the characteristics of low production cost, simple operation process, short production cycle and the like in the aspect of traditional Chinese medicine purification and impurity removal.

Owner:武汉正天成生物科技有限公司

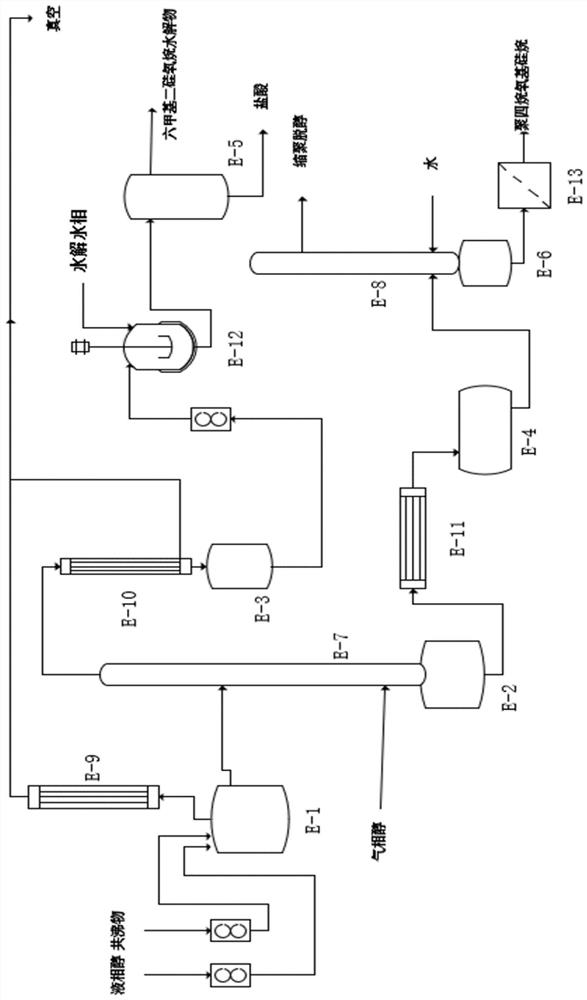

Method and device for comprehensively utilizing organosilicon monomer azeotrope by utilizing alcoholysis process

The invention provides an alcoholysis process of an organosilicon monomer azeotrope and a method for comprehensively utilizing the organosilicon monomer azeotrope based on the alcoholysis process. According to the alcoholysis process, under the vacuum condition, azeotrope is sequentially subjected to a liquid-phase alcoholysis reaction and a gas-phase alcoholysis reaction with liquid-phase alcoholand gas-phase alcohol, the process does not need to carry out low-boiling-point substance removal treatment on the azeotrope in advance, process steps and equipment investment are reduced, and energyconsumption and cost are reduced; meanwhile, the alcoholysis efficiency is high, generated hydrogen chloride can be removed in time, side reactions are avoided, and the alcohol consumption is obviously reduced. A process for preparing polysiloxane from tetraalkoxysilane and a process for preparing hexamethyldisiloxane by hydrolyzing trimethylchlorosilane are added at the downstream of an alcoholysis process, so that the aim of comprehensively utilizing azeotrope is fulfilled.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Condensation type floral water and preparation method thereof

InactiveCN101268990APromotes rapid-release onset of actionReduce alcohol consumptionCosmetic preparationsToilet preparationsBorneolAlkalizing agent

The invention discloses a condensation type toilet water and a preparation method thereof; the condensation type toilet water mainly consists of the ingredients with the shares by weight: 0.1 to 1 share of menthol, 0.2 to 2 shares of borneol, 20 to 30 shares of alcohol, 0.5 to 5 shares of skin care ingredient, 0.03 to 2 shares of macromolecule resin, 0.1 to 1 share of acidifying or alkalizing agent and 59 to 79.07 shares of water. The preparation method is that the menthol and the borneol which are matched according to the proportion are dissolved in the alcohol, and the macromolecule resin is dispersed in water, after being evenly stirred at high speed, the mixture is added with the skin care ingredient to be stirred evenly and at last is added with the acidifying or alkalizing agent; the pH of the preparation is adjusted to be 6.5 to 7.5; finally, the mixture is mixed into the alcohol that is dissolved with the menthol and the borneol, so as to obtain the finished product. The finished product of the condensation type toilet water is of semisolid condensation form, which is immediately transformed into liquid form when being smeared on the skin, thereby promoting the active ingredient to be released rapidly to take effect; after condensation type toilet water is smeared on the skin, no residue is left on the skin; the condensation type toilet water also can greatly reduce the using quantity of the alcohol, and dose not stimulate the skin, can be directly smeared on the skin without being diluted and is convenient for use.

Owner:佛山拜澳生物科技有限公司

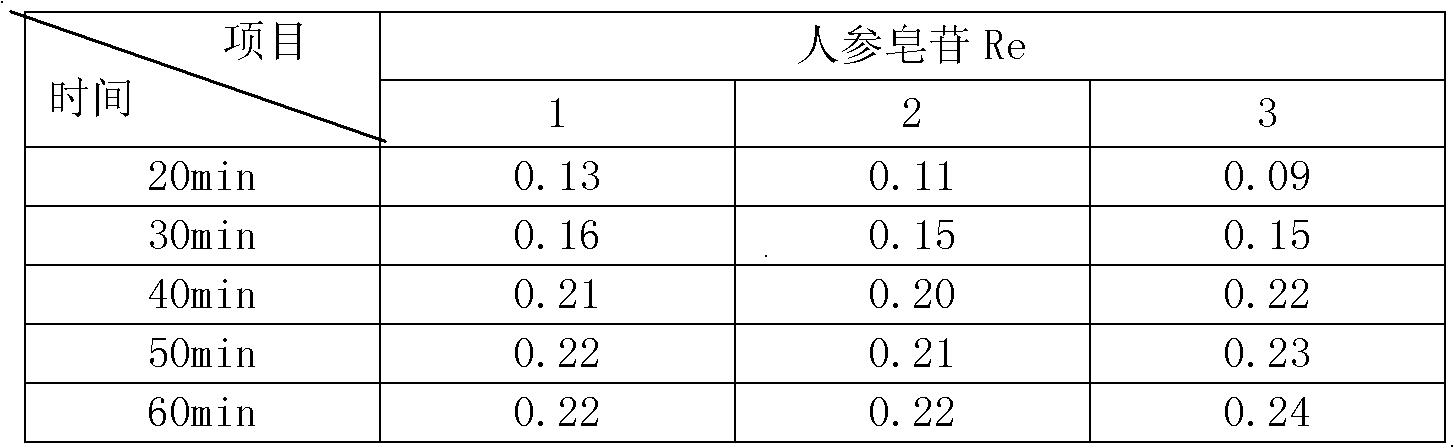

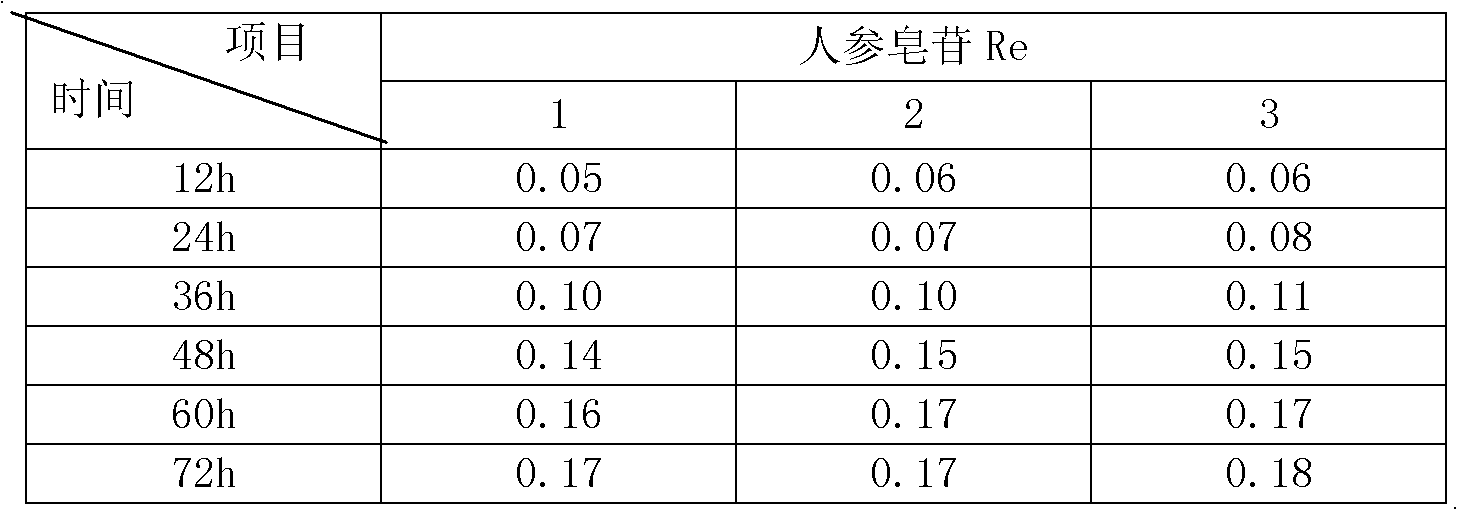

Method for preparing ultrasonic extracted Chinese medicinal preparation for treating qi deficiency

InactiveCN102119945AImprove clinical outcomesQuality improvementDigestive systemPlant ingredientsMedicineAdditive ingredient

The invention discloses a method for preparing an ultrasonic extracted Chinese medicinal preparation for treating qi deficiency, which belongs to the technical field of traditional Chinese medicaments. The method comprises the following steps of: crushing ginseng into coarse powder, putting the coarse powder into an ultrasonic extractor, adding 30 percent ethanol in an amount which is 3 times weight of the coarse powder, starting ultrasonic equipment at a temperature of between 20 and 25 DEG C, performing ultrasonic treatment for 40 minutes, filtering, reclaiming the ethanol, concentrating the filtrate to original amount, adding the ethanol in an amount which is 3 times weight of the concentrate, stirring, standing, taking the supernate, reclaiming the ethanol, and concentrating the supernate to 100ml; and adding sodium benzoate, stirring the solution uniformly, regulating the ethanol content to be 20 to 30 percent, standing at a temperature of between 5 and 10 DEG C, taking the supernate, filtering the supernate, adding water till 1,000ml, standing for 7 days at a temperature of between 5 and 10 DEG C, taking the supernate, filtering the supernate, and packing the supernate to obtain the preparation. By adopting the advanced ultrasonic extraction technology, the effective ingredients based on ginsenoside in the preparation are obviously improved, the quality and the curative effect of the medicament are improved, the clinical effect of the preparation is improved, the yield and the purity of the product are improved, the cost is saved, and the method is suitable for large-scale production operation.

Owner:TONGHUA YUSHENG PHARMA

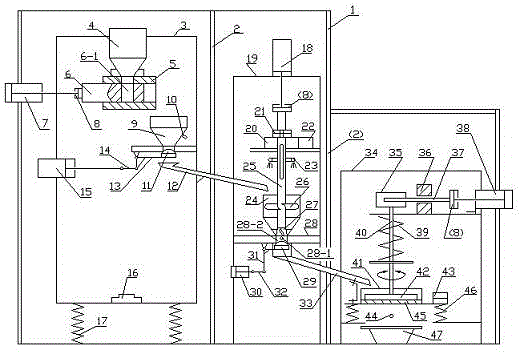

Gunpowder ethyl alcohol blending unit

InactiveCN104949583AImprove the mixing effectSmall granularityRotary stirring mixersFireworksProduction rateAlcohol

The invention discloses a gunpowder ethyl alcohol blending unit. The inner portion of a hood is divided into three zones through partitioning plates. A quantifying grouping machine frame, an ethyl alcohol blending machine frame and an aggregate-removing machine frame are arranged respectively. A material groove penetrates through the partitioning plates and is connected with the three parts. The gunpowder ethyl alcohol blending unit mainly comprises a large hopper, a quantifying shaft, a material receiving hopper, a vertical blending barrel, a speed reducer, an anti-explosion motor, an ethyl alcohol spraying pipe, a vibration screen, a scraping plate and a hot air opening. The four functions of quantifying grouping, ethyl alcohol blending, aggregate removing and drying are integrated, using is safe and sanitary, productivity is high, and ethyl alcohol and manpower are saved.

Owner:陈锐

Preparation method for health-care liquor

InactiveCN109432346ADelicious wineNo dizzinessDigestive systemAntinoxious agentsSide effectHeadaches

The invention discloses a preparation method for health-care liquor, which is characterized in that the needed materials are: 15 percent of common aucklandia roots, 15 percent of flos caryophylli, 15percent of sandalwood, 10 percent of India madder roots, 5 percent of villous amomum fruits, 10 percent of fermented red rice, 5 percent of radix ginseng, 8 percent of hairy antlers, 7 percent of deersinew and 15 percent of whitish honey. The specific operation steps are as follows: the materials are weighed according to the contents, then the common aucklandia root, flos caryophylli, sandalwood,India madder root, villous amomum fruit and fermented red rice are beaten into powder, which is then mixed with whitish honey and soaked into liquor, the liquor is loaded into a bottle, then thee radix ginseng, hairy antlers and deer sinew are loaded into the bottle, and the bottle is stored. According to the invention, the Chinese medicinal materials are medicinal and edible medicinal materials,and cooperate with the unique production process, so that the medicinal liquor is safe and does not have any toxic and side effects after being drunk for a long time; by soaking with whitish honey, the health-care liquor turns red, tastes good, smells fragrant, and is slightly sweet and not hot for the throat, the health-care liquor does not impair the stomach and the liver, people do not feel dizziness and headache after sobering up after drinking, and do not have a bad feeling and reaction after drinking, and the health-care liquor can decrease drinking capacity and benefit health, is sweetand delicious for men and women to drink, and has a nourishing effect.

Owner:宋宪宗 +1

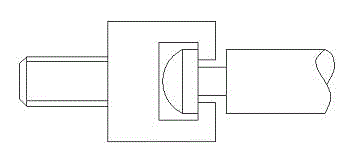

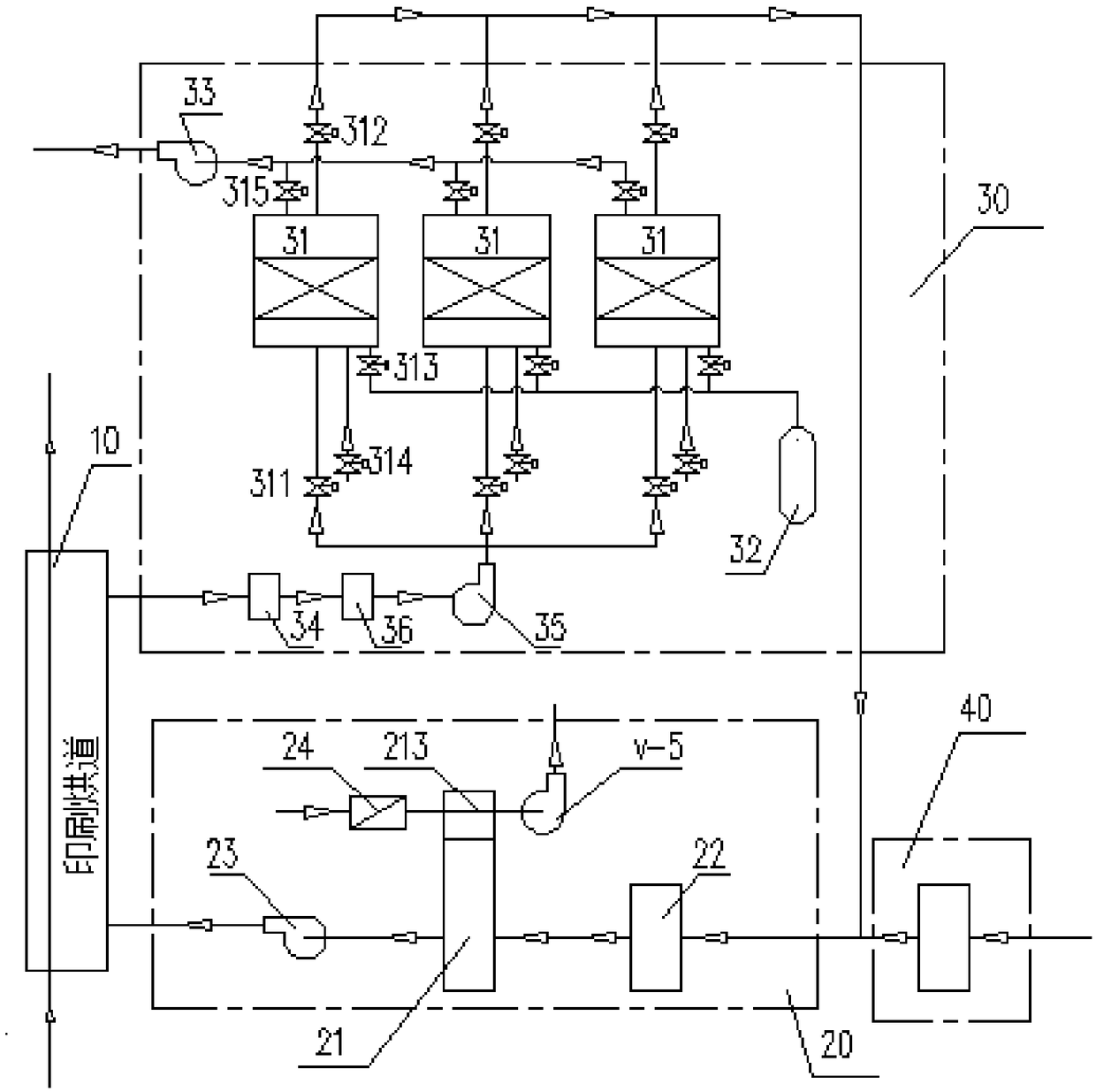

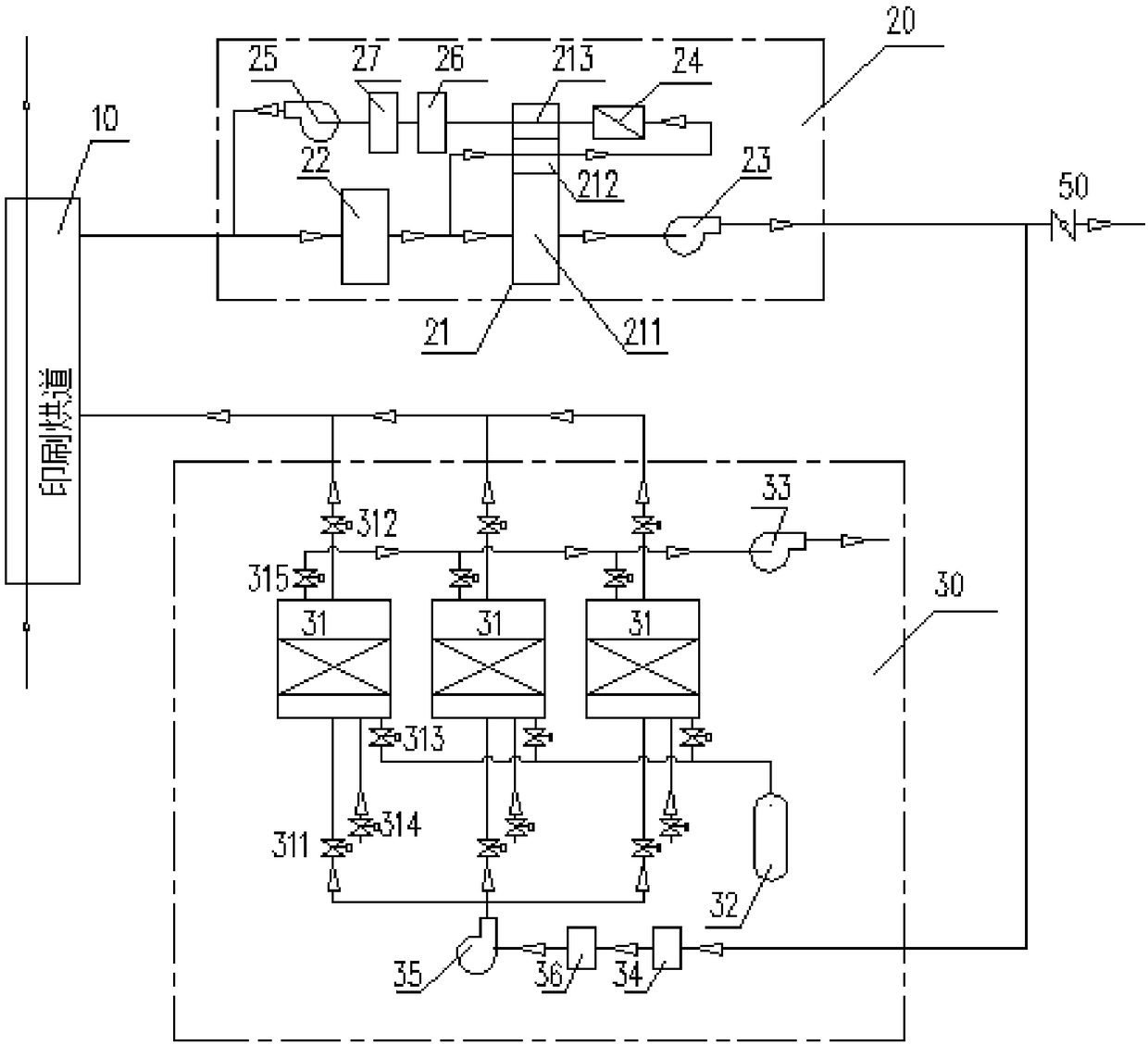

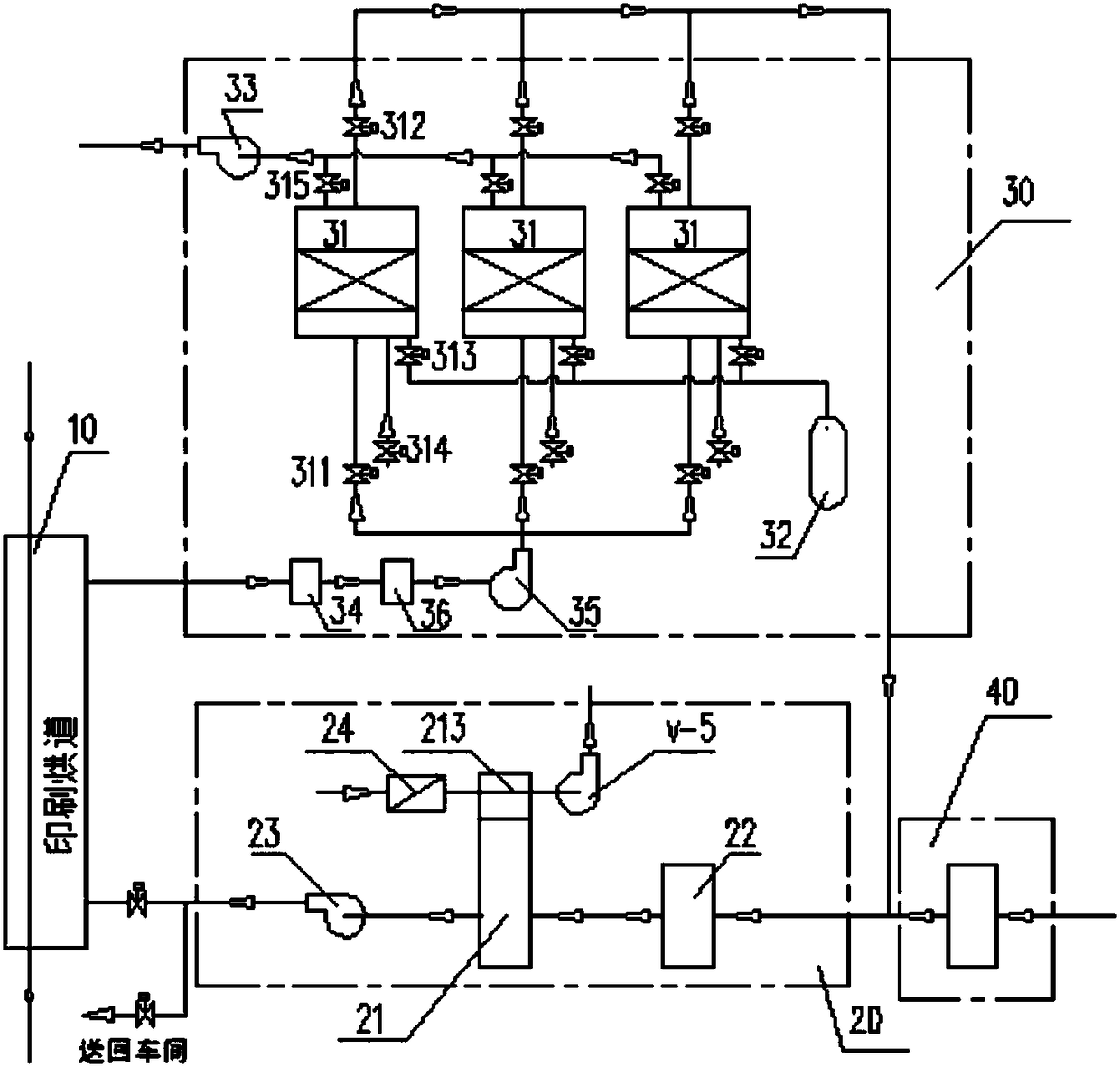

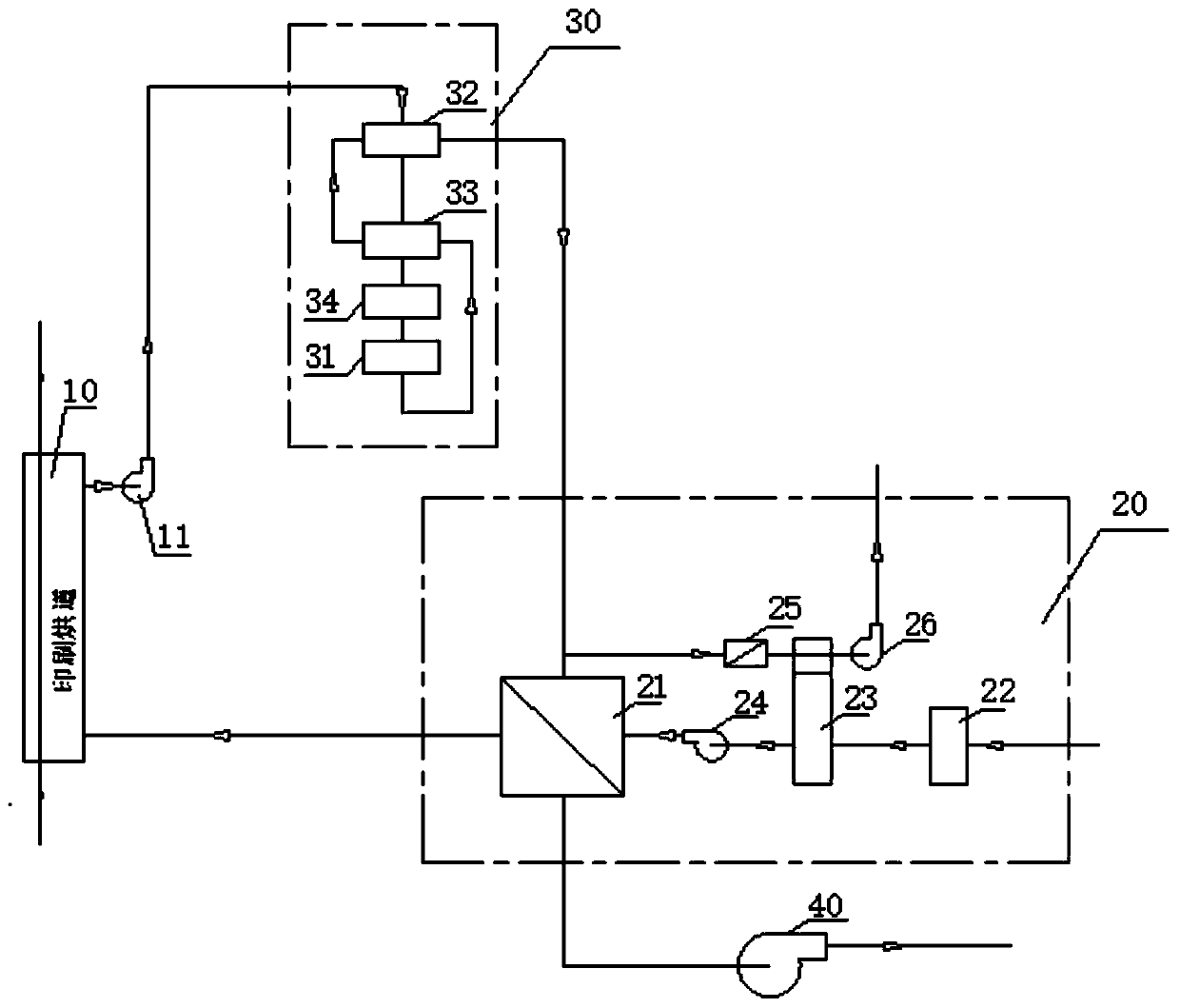

Printing ink drying and exhaust gas treatment system

ActiveCN108528027AGood for volatilizationLow drying temperatureDispersed particle separationIncinerator apparatusDiluentPulp and paper industry

The invention discloses a printing ink drying and exhaust gas treatment system. The printing ink drying and exhaust gas treatment system is applied to a printing drying tunnel, and comprises a dehumidifying unit and a catalytic combustion unit; an outlet of the dehumidifying unit communicates with an air inlet of the printing drying tunnel; an air exhaust port of the printing drying tunnel communicates with an air inlet of the catalytic combustion unit; the dehumidifying unit comprises a dehumidifying device and a heat exchanger; an inlet of the dehumidifying device communicates with the outside; the outlet of the dehumidifying device communicates with a first inlet of the heat exchanger; a first outlet of the heat exchanger communicates with the outlet of the dehumidifying unit; the catalytic combustion unit comprises a catalytic bed; and air entering the air inlet of the catalytic combustion unit passes through the catalytic bed, a second inlet of the heat exchanger, and a second outlet of the heat exchanger sequentially, and communicates with the outside. According to the printing ink drying and exhaust gas treatment system, dry air provided by the dehumidifying unit can increase the water consumption of a diluent, reduce the amount of alcohol usage, and save costs; heat generated by the exhaust gas treatment system is used for drying, so that the energy consumption for drying is reduced, and the exhaust pollution is reduced.

Owner:广州黑马科技有限公司

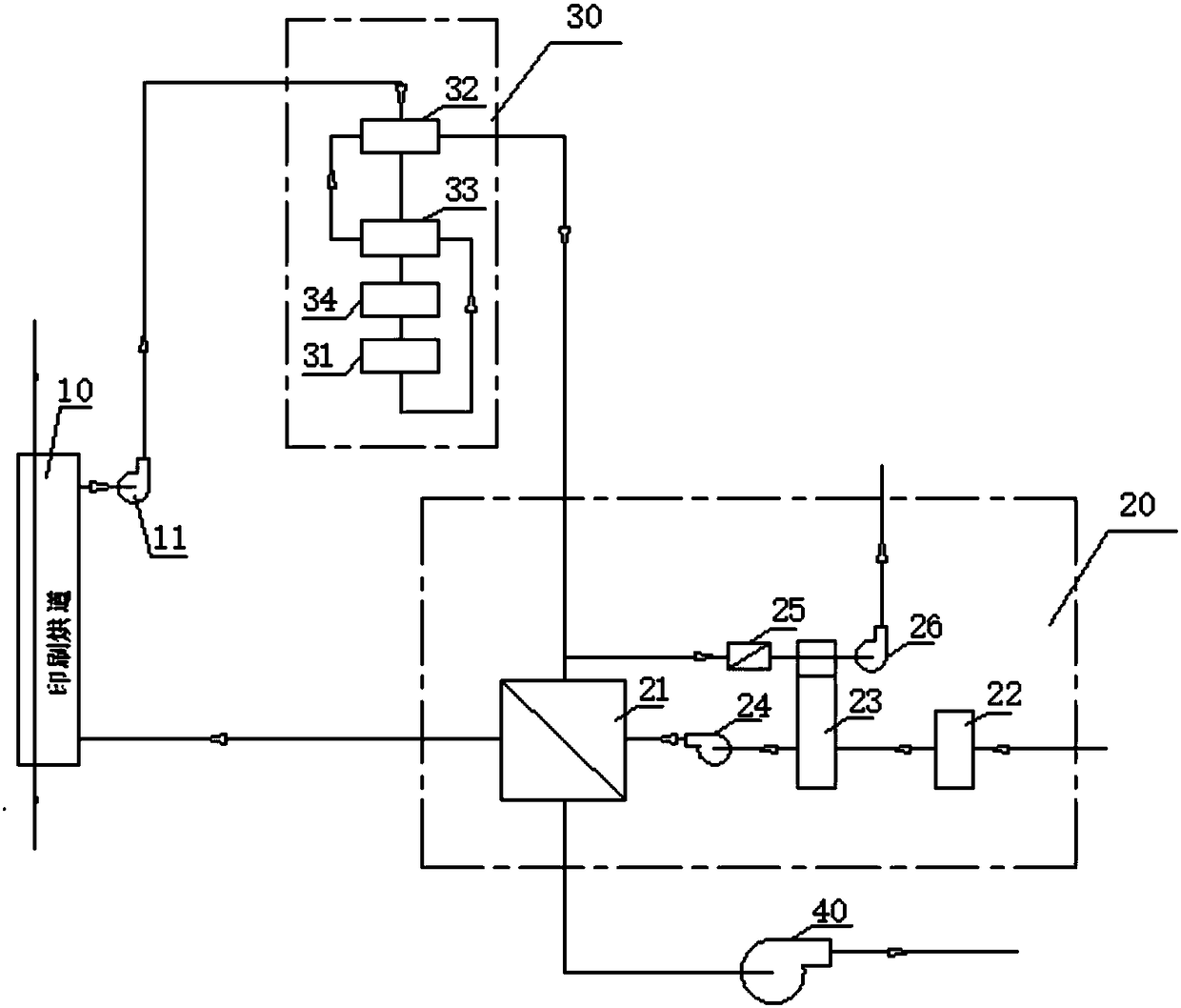

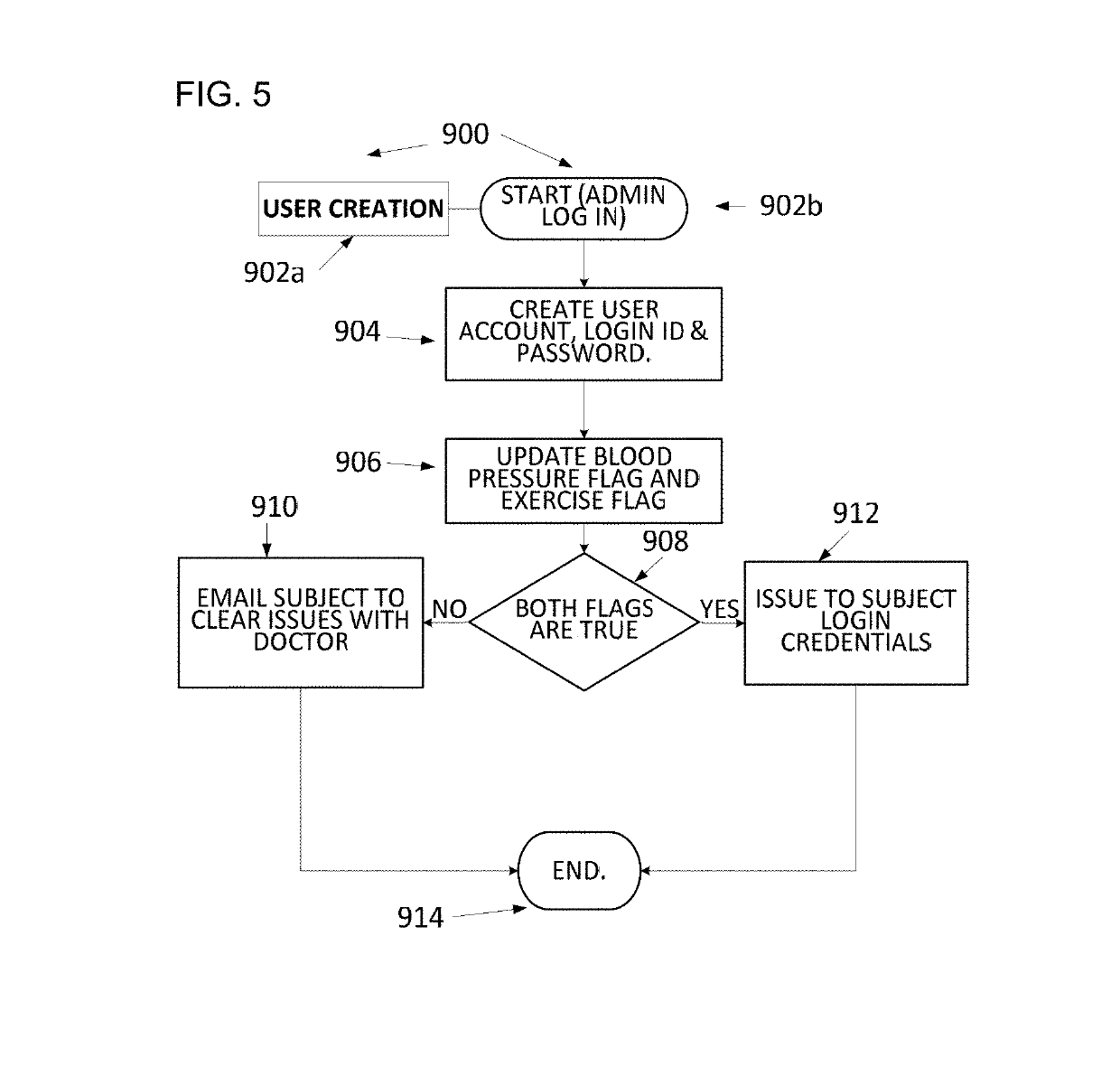

Hypertension prevention app and web based tools

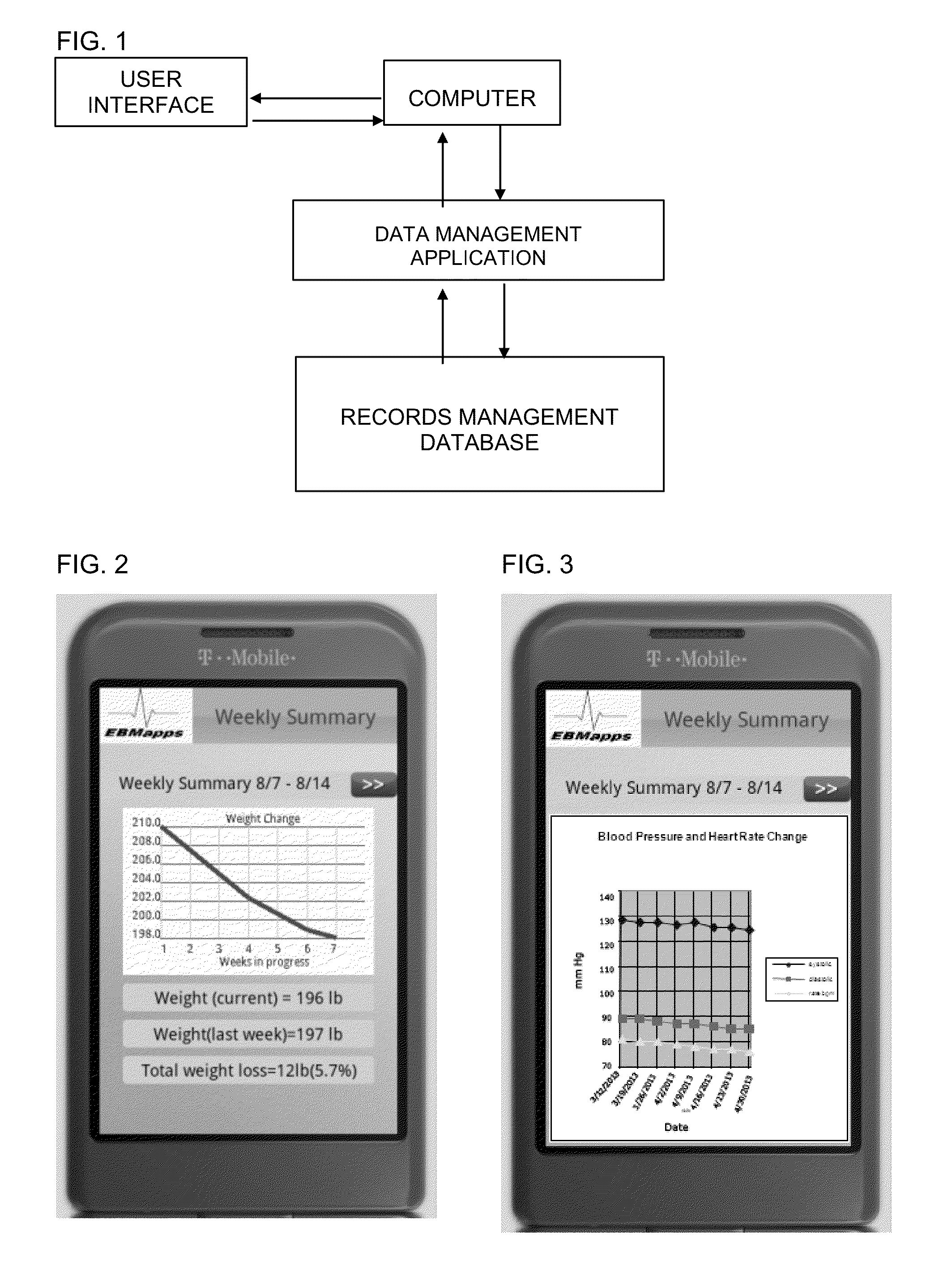

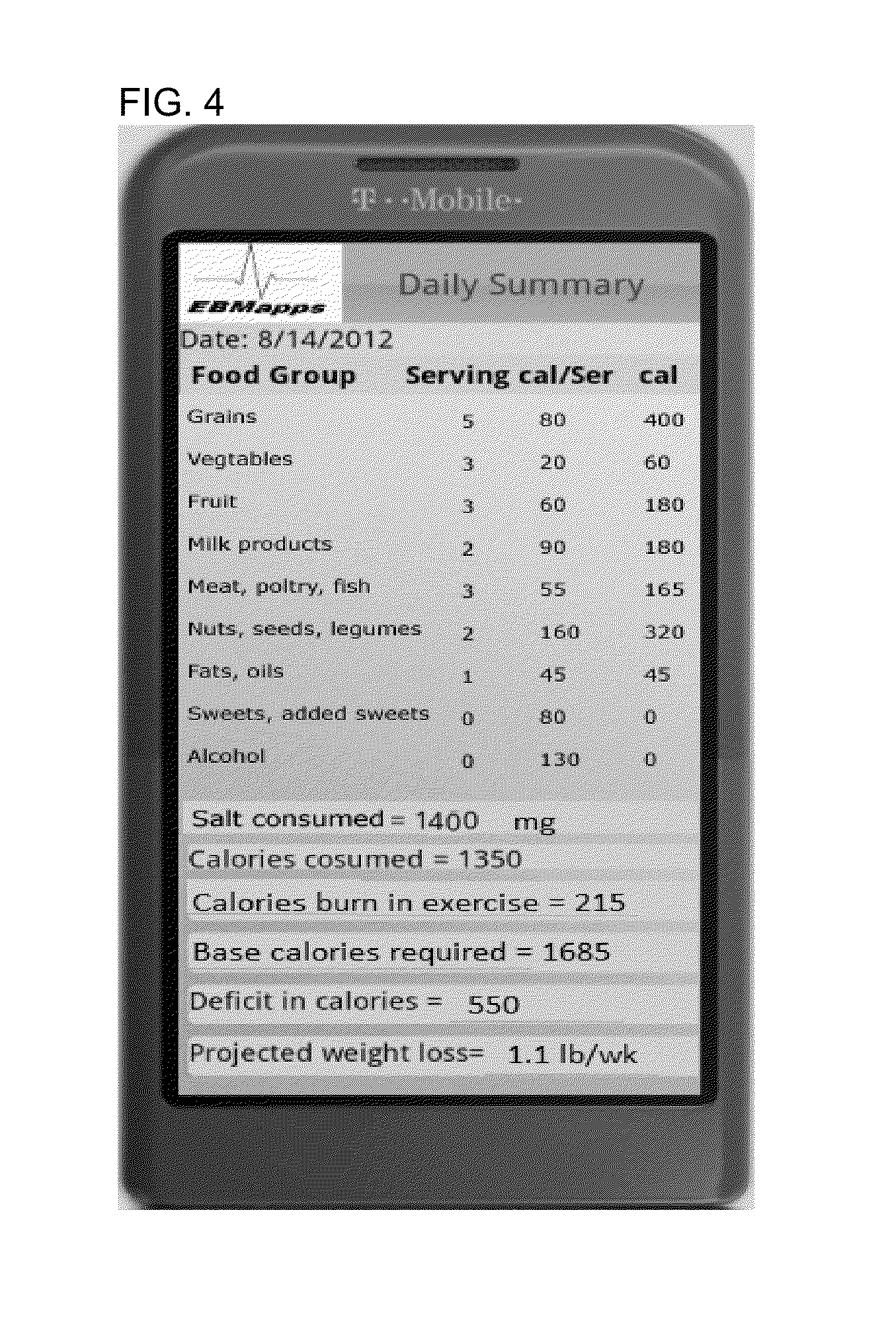

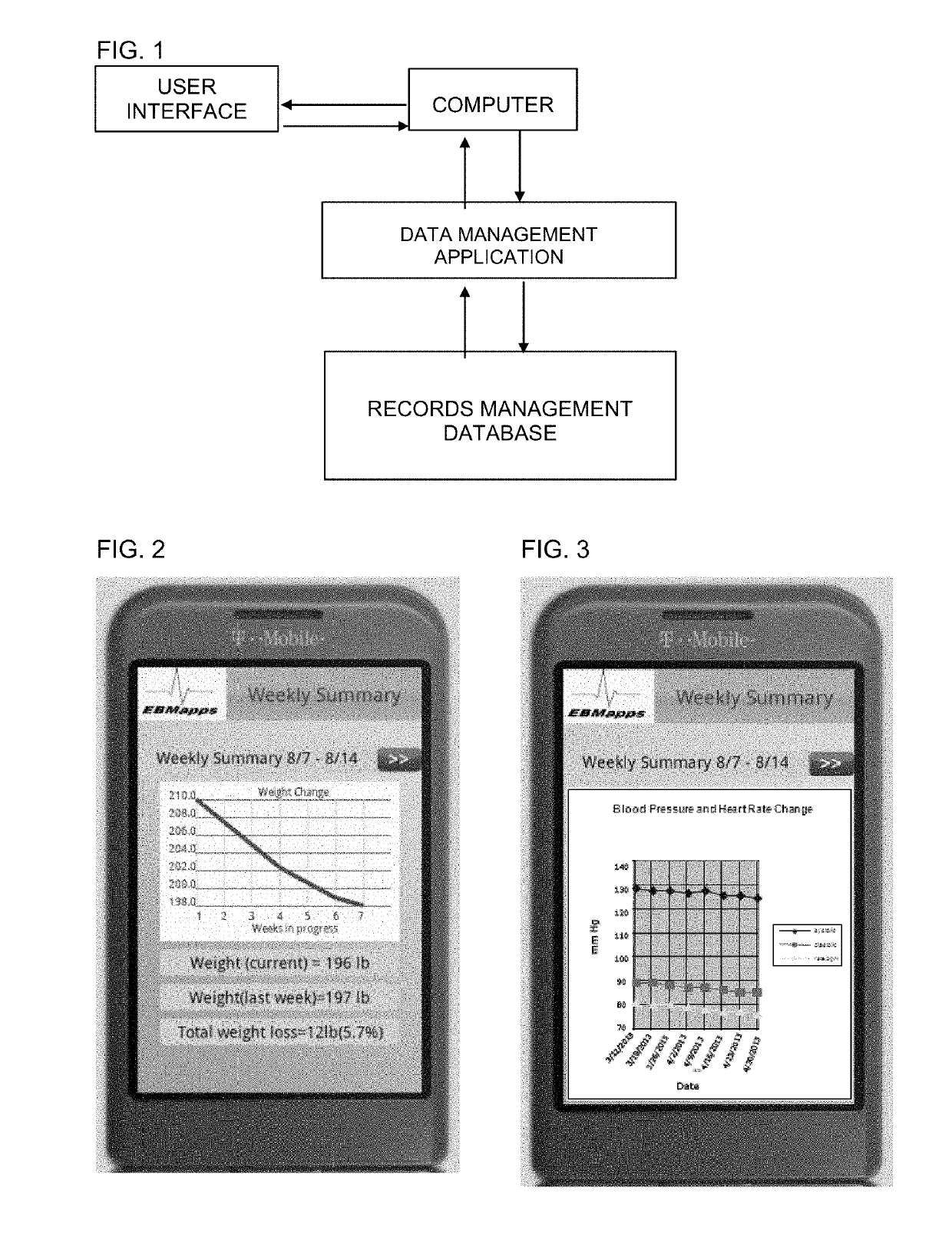

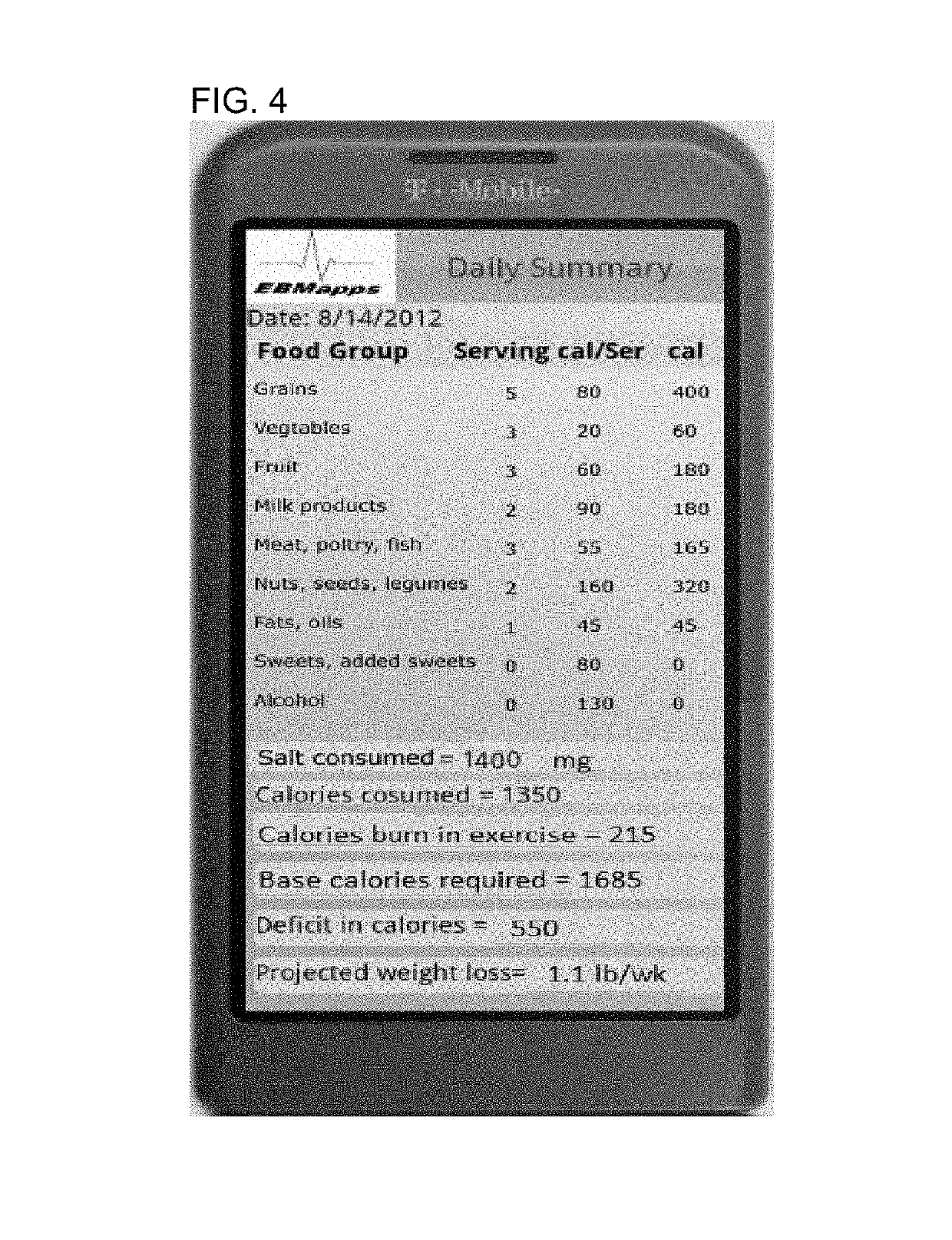

InactiveUS20160089077A1Reduce consumptionAdequate exercisePhysical therapies and activitiesComputer-assisted medical data acquisitionWeb serviceApplication software

A computer system and method is disclosed as a support structure for patients with hypertension or prehypertension to encourage life style changes leading to dietary control, increase exercise and blood pressure control. The method includes automated messages and responses delivered in real time to encourage appropriate actions by the patient. A diary feature is provided for user input of various relevant parameters, such as foods consumed, exercise activities, body weight, blood pressure, and heart rate. The computer system and method may be implemented on a mobile computing device, such as a smart phone or wearable, a conventional personal computer, or a web service. Most functions will be provided on the mobile device, but some housekeeping and data visualization functions may be limited to the personal computer or web service implementations.

Owner:GERONIMO BUTTON CHRISTINE TINIO +2

Hypertension prevention app and web based tools

InactiveUS20190159720A1Reduce consumptionAdequate exercisePhysical therapies and activitiesNutrition controlWeb serviceFood consumption

A computer system and method is disclosed as a support structure for patients with hypertension or prehypertension to encourage life style changes leading to dietary control, increase exercise and blood pressure control. The method includes automated messages and responses delivered in real time to encourage appropriate actions by the patient. A diary feature is provided for user input of various relevant parameters, such as foods consumed, exercise activities, body weight, blood pressure, and heart rate. The computer system and method may be implemented on a mobile computing device, such as a smart phone or wearable, a conventional personal computer, or a web service. Most functions will be provided on the mobile device, but some housekeeping and data visualization functions may be limited to the personal computer or web service implementations.

Owner:GERONIMO BUTTON CHRISTINE TINIO +2

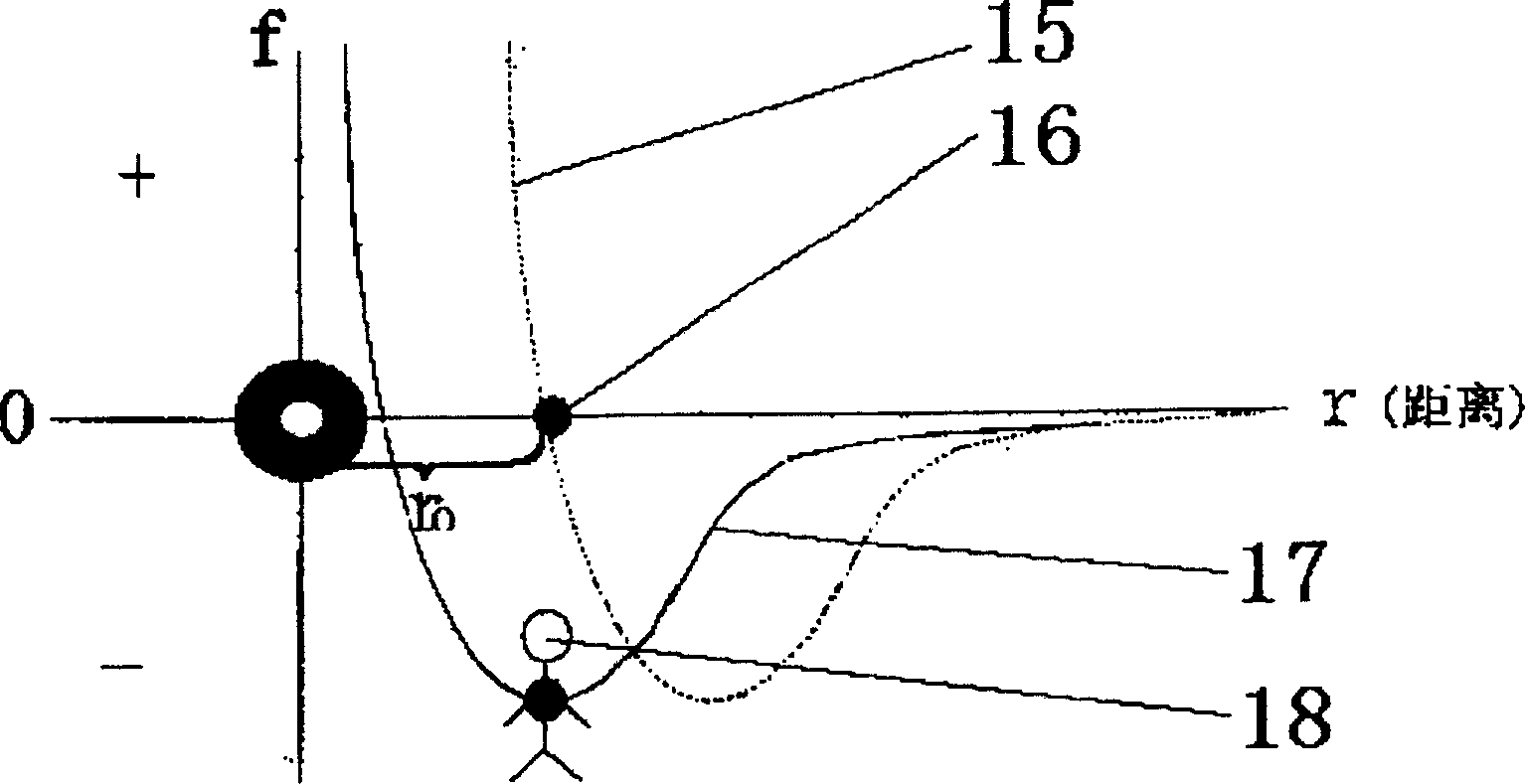

Stimulation-free multifunctional high-energy safety buoyancy field

InactiveCN1488327ABest charge strength valueAvoid enteringWater/sewage treatmentBathing devicesHuman bodySurface ocean

The invention refers to an unexciting multifunctional high-energy safe buoyancy field, adopting the condensed liquid of regulating and controlling agent extracted from clinical sea mine as main buoyancy liquid component. The agent contains trace metal ions with different radius and different ion valence. These high-energy metal ions and linear catenarian collective water molecules make the actions of cutting and coupling to develop the nano agglomerate structure with positive charge, which leads the buoyancy liquid into the buoyancy field to make human body reach the lowest energy position state. The cell of human body on the magnetized surface change the motion of micro magnetic torque in it, to regulate the gene in the nucleus, so as to eliminate fatigue, enhance immunity of human body and increase body energy.

Owner:金日光

Preparation process of pine bark proanthocyanidin

The invention discloses a manufacturing method to extract pine cyanin, which comprises the following steps: lixiviating, centrifuging, columning; condensing; drying; adopting one pattern of PN700, CAD40, YWD04B1 or YWD09D to adsorb cyanin selectively; washing resin through purified water or deionized water; recycling alcohol through decompressing and distilling; obtaining the dried powder throughspraying drying tower.

Owner:浙江瑞康生物技术有限公司

Active substance combination for medicamentous therapy of habituation of or habitual material or narcotics

InactiveCN1527711AReduce alcohol consumptionNervous disorderAmide active ingredientsNarcoticBULK ACTIVE INGREDIENT

The invention relates to an active ingredient combination of at least one modulator of the cholinergic system and at least one substance with an anti-excitatory action for treating a dependence on addictive substances or narcotics, in particular for treating alcoholism.

Owner:HF ARZNEIMITTELFORSCHUNG

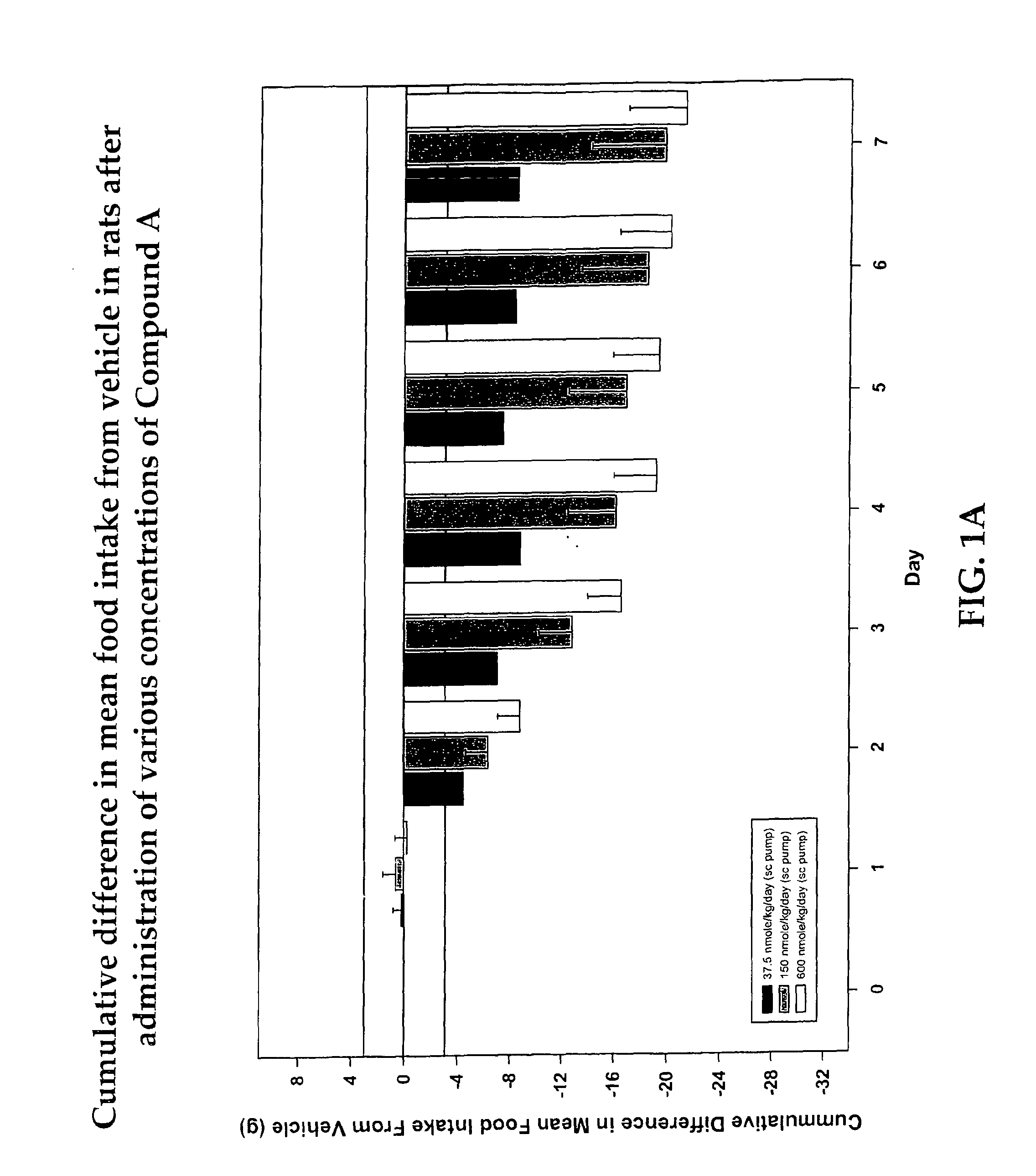

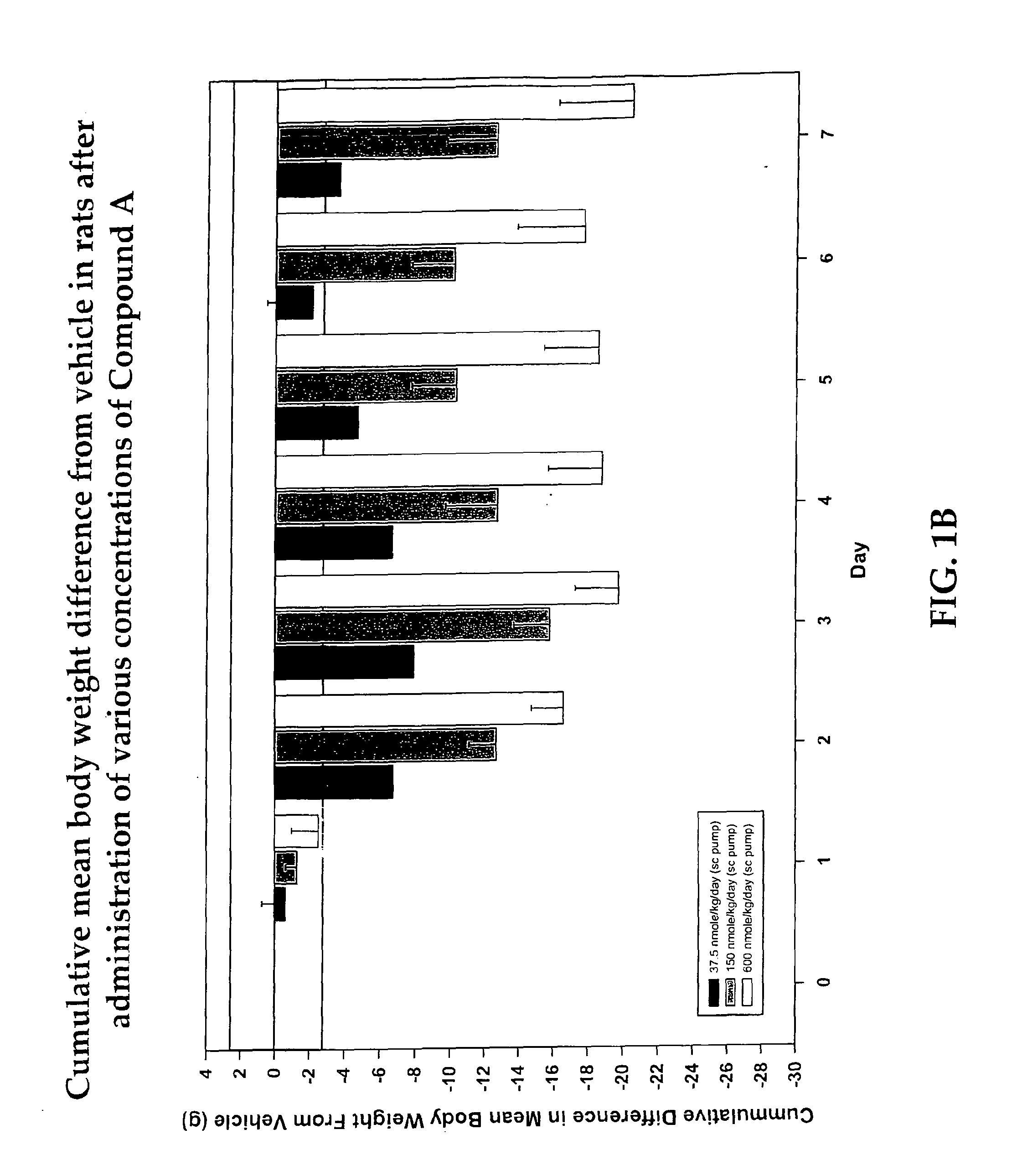

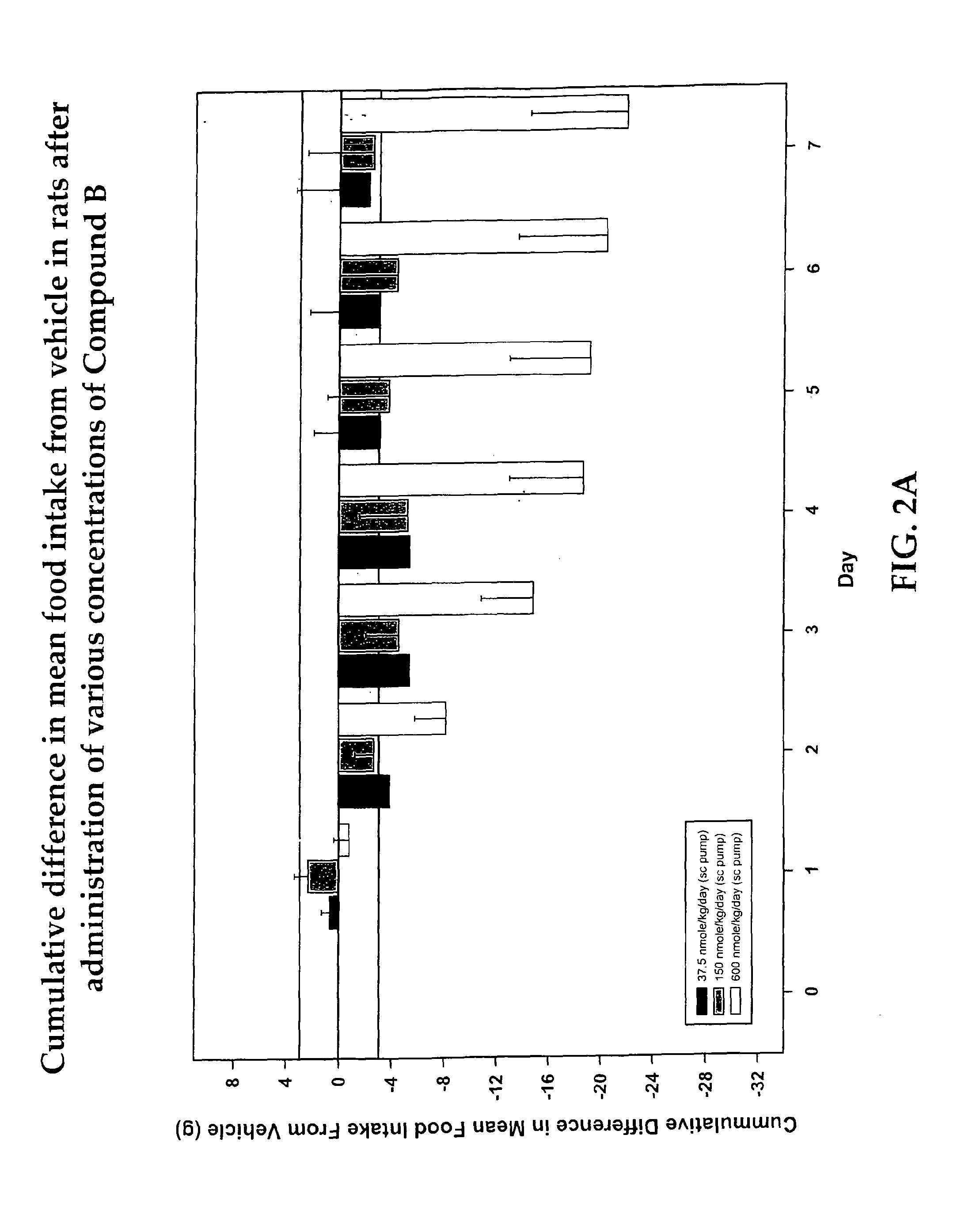

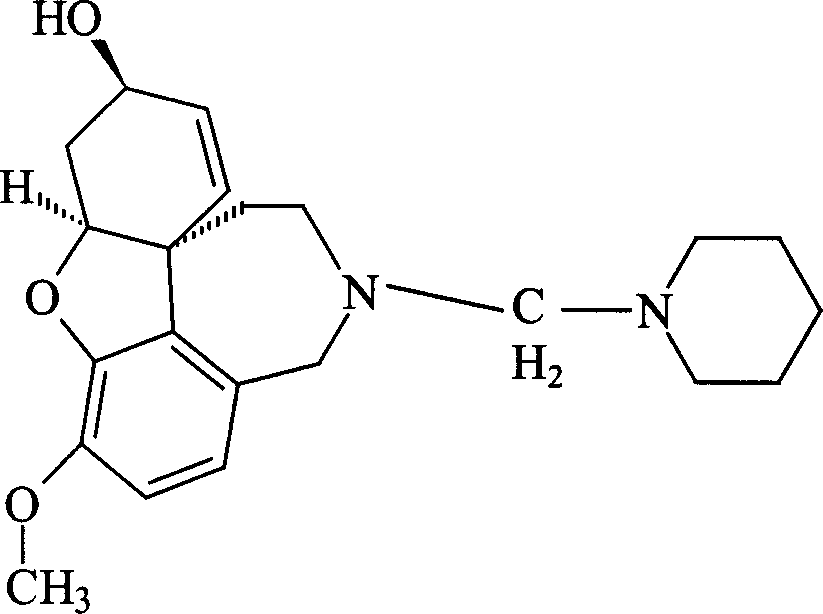

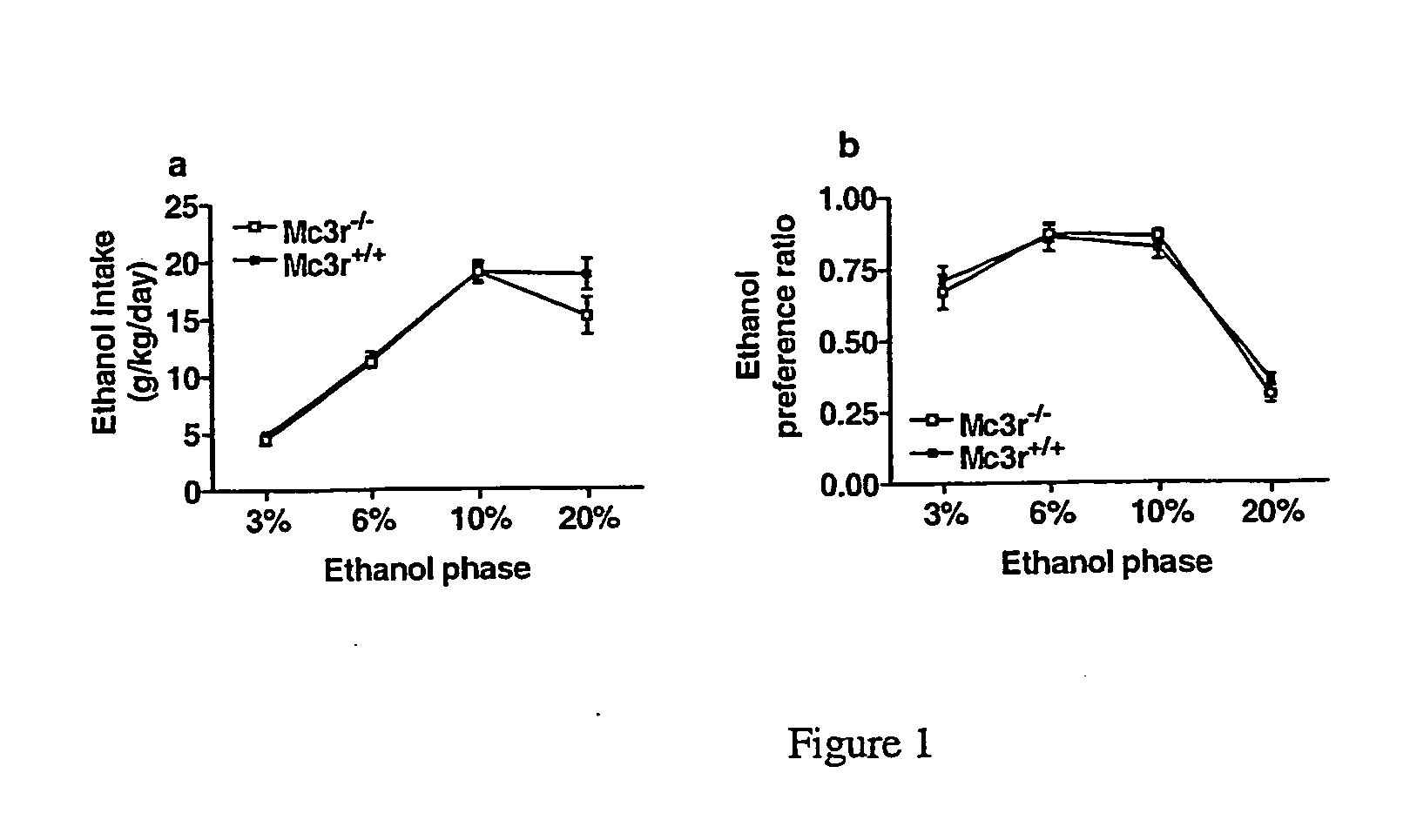

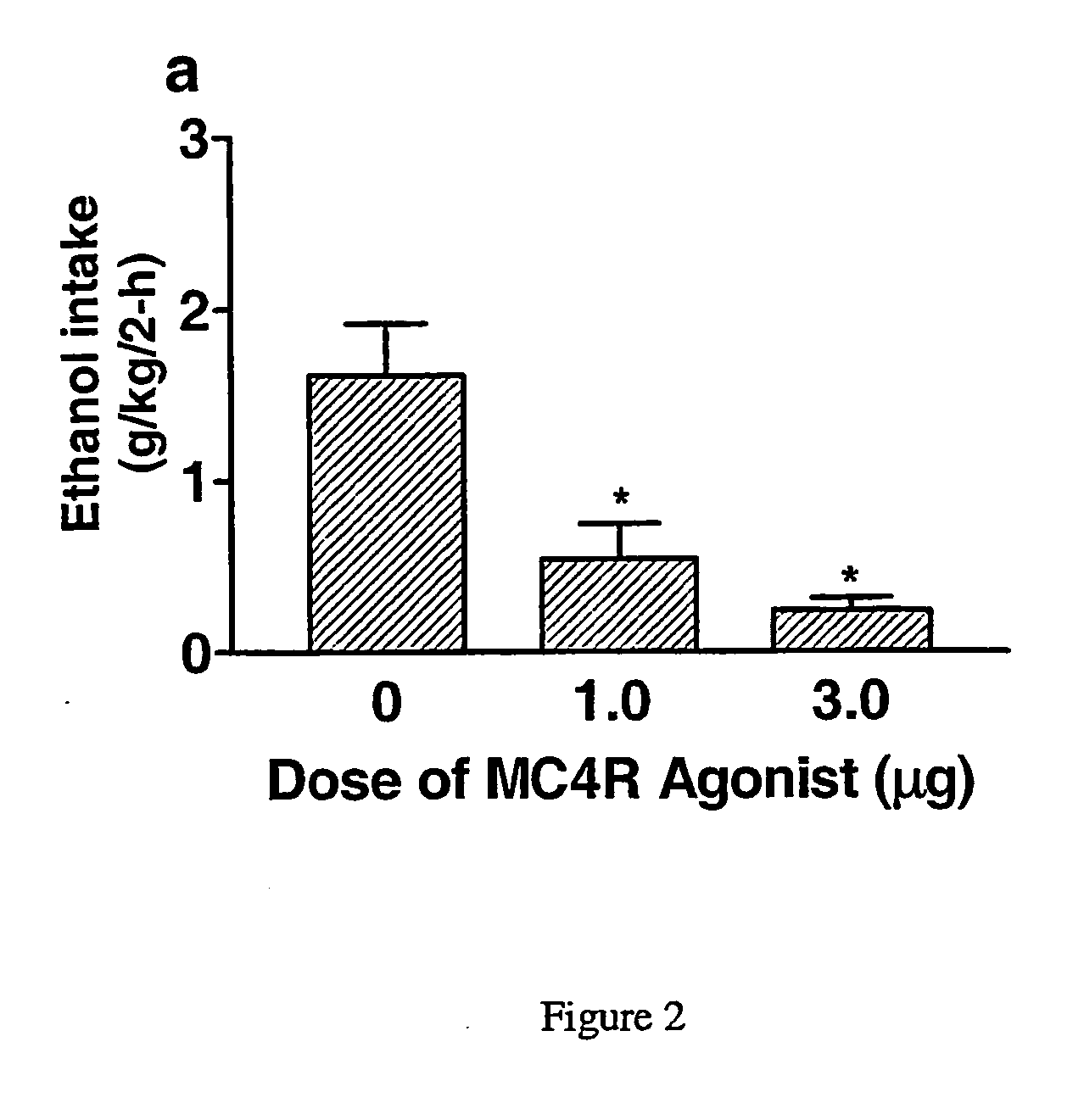

Inhibition of voluntary ethanol consumption with selective melanocortin 4-receptor agonists

InactiveUS20070155660A1Reduce alcohol consumptionPrevent drinkingNervous disorderMetabolism disorderAlcoholismsAlcohol-related disorders

The present invention relates to methods of inhibiting or reducing voluntary alcohol consumption in a subject comprising administering a selective melanocortin 4 receptor agonist to said subject. The present invention further relates to methods of treating or preventing alcoholism, alcohol abuse, and alcohol related disorders in a subject comprising administering a selective melanocortin 4 receptor agonist to said subject. The present invention further provides for pharmaceutical compositions and medicaments useful in carrying out these methods.

Owner:MERCK SHARP & DOHME CORP +1

Stimulation-free multifunctional high-energy safety buoyancy field

InactiveCN1226027CBest charge strength valueAvoid enteringWater/sewage treatmentBathing devicesHuman bodySurface ocean

The invention refers to an unexciting multifunctional high-energy safe buoyancy field, adopting the condensed liquid of regulating and controlling agent extracted from clinical sea mine as main buoyancy liquid component. The agent contains trace metal ions with different radius and different ion valence. These high-energy metal ions and linear catenarian collective water molecules make the actions of cutting and coupling to develop the nano agglomerate structure with positive charge, which leads the buoyancy liquid into the buoyancy field to make human body reach the lowest energy position state. The cell of human body on the magnetized surface change the motion of micro magnetic torque in it, to regulate the gene in the nucleus, so as to eliminate fatigue, enhance immunity of human body and increase body energy.

Owner:金日光

Fractional extraction method of aloe polysaccharide

This invention provides a fractional extraction method of aloe polysaccharides, it adds 8-10 times of 95% alcohol into concentrated aloe product, standing and precipitating after mixing, then filtering, reclaiming alcohol, collecting aloes crude polysaccharide, after adding water and mixing to dissolve, gradually passing the ultrafiltration membrane whose molecular cut off is 200000-4000, then passing nano-filter membrane to concentrate, getting aloes polysaccharides of different molecular weight.

Owner:云南万绿生物股份有限公司

Condensation type floral water and preparation method thereof

InactiveCN101268990BOvercoming defects in releasing active ingredientsQuick release onsetCosmetic preparationsToilet preparationsMentholAlcohol

Owner:佛山拜澳生物科技有限公司

Biodiesel preparing method

InactiveCN105602632ASolve the disadvantages of productionMild reaction conditionsFatty acid esterificationBiofuelsBiodieselEvaporation

The invention belongs to the technical field of biodiesel preparation and particularly relates to a biodiesel preparing method. Waste grease is used for preparing biodiesel through an acid-base two-step synthesizing method. The biodiesel preparing method comprises the following steps that firstly, the waste grease is subjected to acid washing with water, activated carbon adsorption and centrifugal separation treatment; secondly, methyl alcohol or ethyl alcohol, carbonic ester and an acid catalyst are added and heated for reflux esterification; thirdly, an esterified product is added with alkali to regulate pH, and methyl alcohol or ethyl alcohol and an alkali catalyst are added and heated for reflux esterification exchange; fourthly, after a reaction is finished, methyl alcohol or ethyl alcohol is steamed out through reduced pressure, washing, centrifugal layering and film evaporation drying are carried out, and biodiesel is obtained. The biodiesel preparing method has the advantages of being high in yield and reaction speed, low in energy consumption and production cost and the like, and is suitable for commercialized production.

Owner:SHANDONG TAIDE NEW ENERGY

Printing ink drying system

ActiveCN108528028AGood for volatilizationLow drying temperaturePrinting press partsEvaporationDiluent

The invention discloses a printing ink drying system. The printing ink drying system is applied to a printing drying tunnel, and comprises a dehumidifying unit and a recycling unit; the dehumidifyingunit comprises a dehumidifying rotating wheel; an inlet of the dehumidifying rotating wheel is connected with an inlet of the dehumidifying unit; a drying gas outlet of the dehumidifying wheel is connected with an outlet of the dehumidifying unit; the recycling unit comprises at least one adsorption tank, a condenser and a drying fan; a first port of the adsorption tank is connected with the inletof the recycling unit; a second port of the adsorption tank is connected with an outlet of the recycling unit; a third port of the adsorption tank is connected with the condenser; a fourth port of the adsorption tank is connected with the outside; and a fifth port of the adsorption tank is connected with the inlet of the drying fan. By adopting the system, air is dried through the dehumidifying unit, and then enters the printing drying tunnel for drying; when used for drying, the dehumidified air can reduce drying temperature, save energy, and also facilitate the evaporation of moisture during a drying process; and the water consumption of a diluent is increased and the amount of alcohol usage is reduced. The recycling unit can be adopted to recycle the discharged alcohol and ammonia gas.

Owner:广州黑马科技有限公司

Method for extracting procyanidine by using pine bark

The invention discloses a method for extracting procyanidine by using pine bark, which comprises the following steps: taking the endodermis of pine bark as a raw material, and adding water which is 10-20 times of the weight of the raw material for extraction to obtain an extracting solution; keeping the extracting solution at the temperature of 50 DEG C to 70 DEG C for 1-2 hours, centrifuging theextracting solution, and removing fine particles and residues to obtain centrifugate; standing the centrifugate for 2-4h to obtain a clarified extracting solution; slowly feeding the clarified extracting solution into a macroporous resin column, carrying out selective adsorption, flushing the resin with purified water or deionized water, discharging impurities, and carrying out hydrolytic washingwith 30-50% alcohol for 2-3 times, so as to obtain an alcohol eluent of procyanidine; further concentrating the eluent to obtain a concentrated solution with the percentage concentration of 11-18%; and drying the concentrated solution at 210-220 DEG C to obtain powdery procyanidine, and packaging the procyanidine after the procyanidine is inspected to be qualified. The process is simple and easy to operate, the raw material is the pine bark which is rich in resource and low in price, and the high additional value of the pine bark is fully developed while the production cost is reduced.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

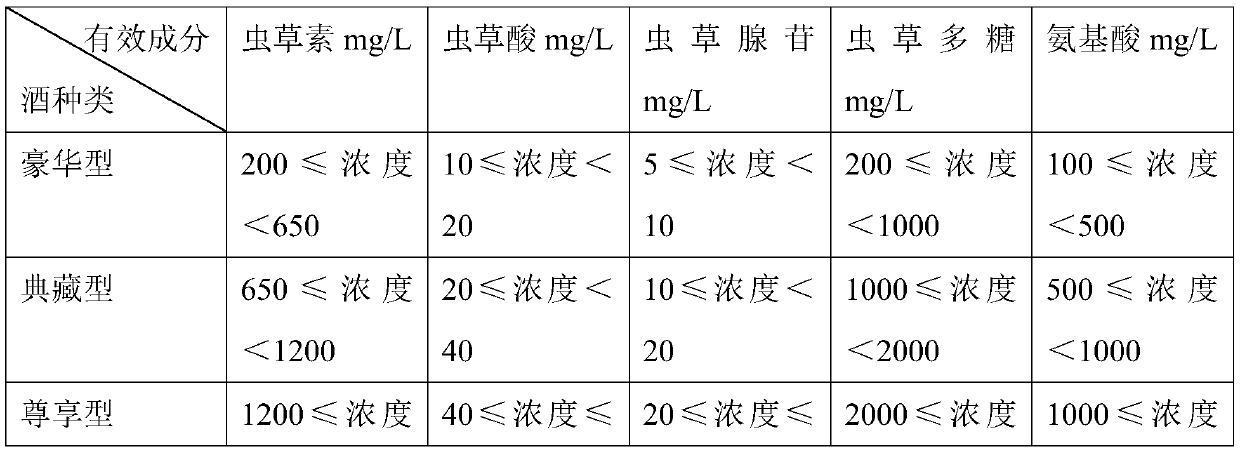

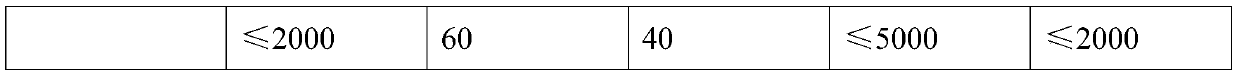

Cordyceps militaris health-care wine and preparation method and application thereof

PendingCN111073785AReduce alcohol consumptionImprove immunityAlcoholic beverage preparationSexual functioningAdenosine

The invention discloses cordyceps militaris health-care wine and a preparation method and application thereof. The health-care wine is mainly prepared by blending cordyceps militaris water extract andChinese liquor with different flavors, and main active components of the health-care wine comprise cordycepin, cordycepic acid, cordyceps adenosine and cordyceps polysaccharide. The health-care winehas the effects of resisting fatigue, protecting liver and heart, moistening lung to tonify qi, improving immunity, enhancing memory, delaying senescence, preventing and treating cardiovascular diseases and the like, and particularly has a remarkable regulating effect on sexual function decline. The content of effective components in the health-care wine is far higher than that of current commercially available products, and the health-care wine is high in quality and suitable for large-scale production.

Owner:LUZHOU PINCHUANG TECH +1

Preparation process of natural extract

PendingCN113318083AAvoid security issuesSolve efficiency problemsOrganic active ingredientsHydrolysed protein ingredientsBiotechnologyComposite film

The invention relates to the field of pharmaceutical preparations, in particular to a preparation process for single components or compositions of polypeptides, polysaccharides and natural Chinese herbal medicine extracts, which comprises the following steps of: mixing at a high speed, atomizing and adding alcohol, fully and uniformly mixing, and dry granulating. The granulated particles can be used for tabletting, filling capsules or filling composite film bags. Compared with a traditional dry granulating process, the granulating process of the invention can solve the problem of single components or compositions of polypeptides, polysaccharides and natural Chinese herbal medicine extracts which are not suitable for dry granulating, and compared with a traditional wet granulating process, the processing steps can be simplified, soft materials are not needed, heating and drying are not needed, the cost is reduced, the productivity is improved, the materials can be effectively prevented from being agglomerated in the granulating process, and therefore the granulating process has the advantages of low cost, high productivity and high efficiency.

Owner:正当年医药科技(广州)有限公司

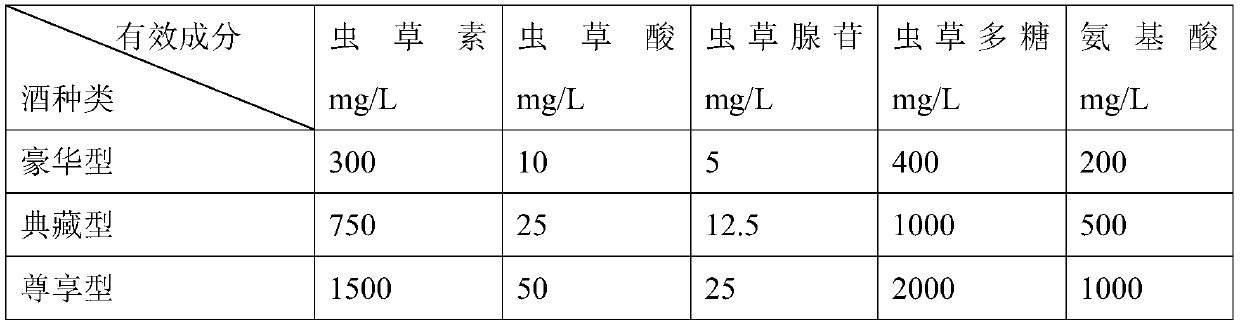

Preparation method of spirulina polysaccharide

InactiveCN111732671AReduce consumptionLow efficiencyOrganic active ingredientsAntineoplastic agentsBiotechnologyEngineering

The invention discloses a preparation method of spirulina polysaccharide. The method comprises the following specific steps: preparing raw materials, extracting a mixture, separating an extract, carrying out cooling, carrying out purifying and precipitating, washing a precipitate, carrying out solid-liquid separation, and carrying out crushing and sieving. According to the invention, damage of spirulina to a polysaccharide structure in a high-temperature drying process is avoided, the yield and the quality of the polysaccharide are improved, the alcohol consumption required by decoloration isreduced, cost is saved, and the method is more practical. The extraction amount of spirulina polysaccharide is increased, the extracted polysaccharide is used for adjuvant therapy drugs on the market,and the effects of resisting tumors, resisting radiation, promoting DNA synthesis and enhancing immunity are achieved. The yield and the quality of the polysaccharide are improved, the alcohol consumption required by decoloration is reduced, the production cost can be greatly reduced, and the quality is improved. The polysaccharide is prepared by taking fresh spirulina as a raw material, any chemical reagent is not required to be added for treatment, chemical residues are avoided, and an experimental result is closer to a required result.

Owner:王志忠

Method for extracting polysaccharides from fishbone of hairtail

The invention discloses a method for extracting polysaccharides from the fishbone of hairtail, comprising the following steps: pretreating the fishbone; adding water and alkali into the fishbone so as to perform alkali treatment; adding protease and a zymoexciter to perform enzymolysis; filtering to obtain filter liquor; adding hydrogen peroxide so as to carry out oxidation treatment on the filter liquor; adding Ca3(PO4)2 so as to decontaminate the filter liquor by adsorption; and performing filtering, alcohol precipitation, dehydration and arefaction to prepare the polysaccharides. The method of the invention has the advantages of simple and practical process, easy operation, low energy consumption, less usage of enzyme, short enzymolysis time, saved alcohol usage, lowered production cost, and good quality and high purity of obtained products.

Owner:SHANDONG MEIJIA GROUP

A printing ink drying and waste gas treatment system

ActiveCN108528027BGood for volatilizationLow drying temperatureDispersed particle separationIncinerator apparatusExhaust fumesProcess engineering

The invention discloses a printing ink drying and exhaust gas treatment system. The printing ink drying and exhaust gas treatment system is applied to a printing drying tunnel, and comprises a dehumidifying unit and a catalytic combustion unit; an outlet of the dehumidifying unit communicates with an air inlet of the printing drying tunnel; an air exhaust port of the printing drying tunnel communicates with an air inlet of the catalytic combustion unit; the dehumidifying unit comprises a dehumidifying device and a heat exchanger; an inlet of the dehumidifying device communicates with the outside; the outlet of the dehumidifying device communicates with a first inlet of the heat exchanger; a first outlet of the heat exchanger communicates with the outlet of the dehumidifying unit; the catalytic combustion unit comprises a catalytic bed; and air entering the air inlet of the catalytic combustion unit passes through the catalytic bed, a second inlet of the heat exchanger, and a second outlet of the heat exchanger sequentially, and communicates with the outside. According to the printing ink drying and exhaust gas treatment system, dry air provided by the dehumidifying unit can increase the water consumption of a diluent, reduce the amount of alcohol usage, and save costs; heat generated by the exhaust gas treatment system is used for drying, so that the energy consumption for drying is reduced, and the exhaust pollution is reduced.

Owner:广州黑马科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com