Preparation method of spirulina polysaccharide

A technology of spirulina polysaccharides and spirulina, which is applied in the direction of pharmaceutical formulas, medical preparations containing active ingredients, organic active ingredients, etc., can solve the problem of long extraction time of spirulina polysaccharides, the inability of spirulina to be self-sufficient, and the limitation of spirulina research, etc. problems, to achieve the effect of reducing the amount of alcohol, avoiding chemical residues, and being more practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

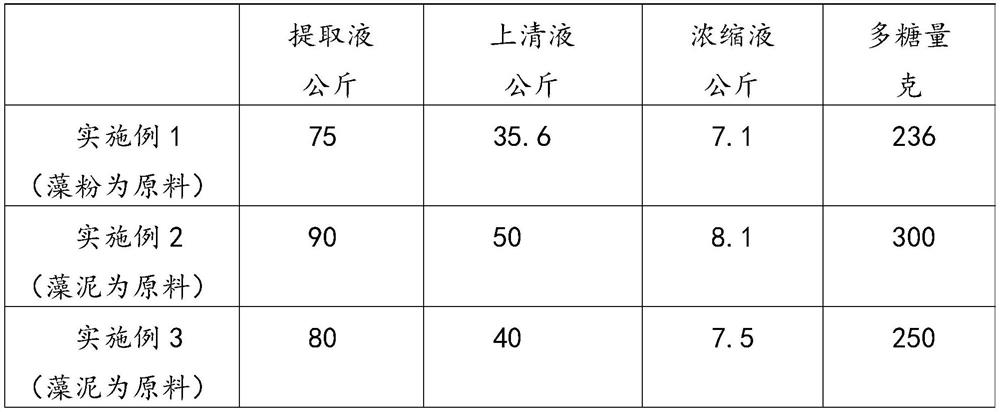

Examples

Embodiment 1

[0025] The invention provides a preparation method of spirulina polysaccharide, the specific steps of the preparation method of spirulina polysaccharide are as follows:

[0026] S1: Preparation of raw materials: 100 parts of spirulina, 10 parts of water, 100 parts of dimethyl sulfoxide, 50 parts of papain, 80 parts of trypsin, 0.2 part of powdered active polypeptide, the required auxiliary materials include: 95 parts by weight percentage 8 parts of ethanol, 10 parts of 95% phenolic formaldehyde and 5 parts of 95% acetone.

[0027] S2: Extraction of the mixture: Put the processed spirulina algae mud into the stainless steel heating pot, inject 100 parts of dimethyl sulfoxide and heat, dissolve the spirulina polysaccharide in dimethyl sulfoxide, heat to boiling, and extract 3-4h, the amount of the extract is three times that of the spirulina to obtain the presoak;

[0028] S3: Separation of the extract: inject the extracted mixture into 50 parts of papain, 80 parts of trypsin a...

Embodiment 2

[0036] The invention provides a preparation method of spirulina polysaccharide, the specific steps of the preparation method of spirulina polysaccharide are as follows:

[0037] S1: Preparation of raw materials: 200 parts of spirulina, 15 parts of water, 200 parts of dimethyl sulfoxide, 100 parts of papain, 90 parts of trypsin, 0.25 parts of powder active polypeptide, the required auxiliary materials include: 95 parts by weight percentage 9 parts of ethanol, 15 parts of 95% phenolic formaldehyde and 10 parts of 95% acetone.

[0038] S2: Extraction of the mixture: Put the processed spirulina algae mud into the stainless steel heating pot, inject 200 parts of dimethyl sulfoxide and heat, dissolve the spirulina polysaccharide in dimethyl sulfoxide, heat to boiling, and extract 3-4h, the amount of the extract is three times that of the spirulina to obtain the presoak;

[0039] S3: Separation of the extract: inject the extracted mixture into 100 parts of papain, 90 parts of trypsi...

experiment example 3

[0048] The invention provides a preparation method of spirulina polysaccharide, the specific steps of the preparation method of spirulina polysaccharide are as follows:

[0049] S1: Preparation of raw materials: 300 parts of spirulina, 20 parts of water, 300 parts of dimethyl sulfoxide, 150 parts of papain, 100 parts of trypsin and 0.3 part of powdered active polypeptide. The required auxiliary materials include: 95 parts by weight percentage 10 parts of ethanol and 20 parts of 95% phenolic aldehyde and 20 parts of 95% acetone;

[0050] S2: Extraction of the mixture: Put the processed spirulina algae mud into the stainless steel heating pot, inject 300 parts of dimethyl sulfoxide and heat, dissolve the spirulina polysaccharide in dimethyl sulfoxide, heat to boiling, and extract 3-4h, the amount of the extract is three times that of the spirulina to obtain the presoak;

[0051] S3: Separation of the extract: inject the extracted mixture into 150 parts of papain, 100 parts of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com