Method and device for comprehensively utilizing organosilicon monomer azeotrope by utilizing alcoholysis process

A technology of azeotrope and organosilicon, applied in the direction of silicon organic compounds, etc., can solve the problems of complex components, long contact time, high ethanol consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

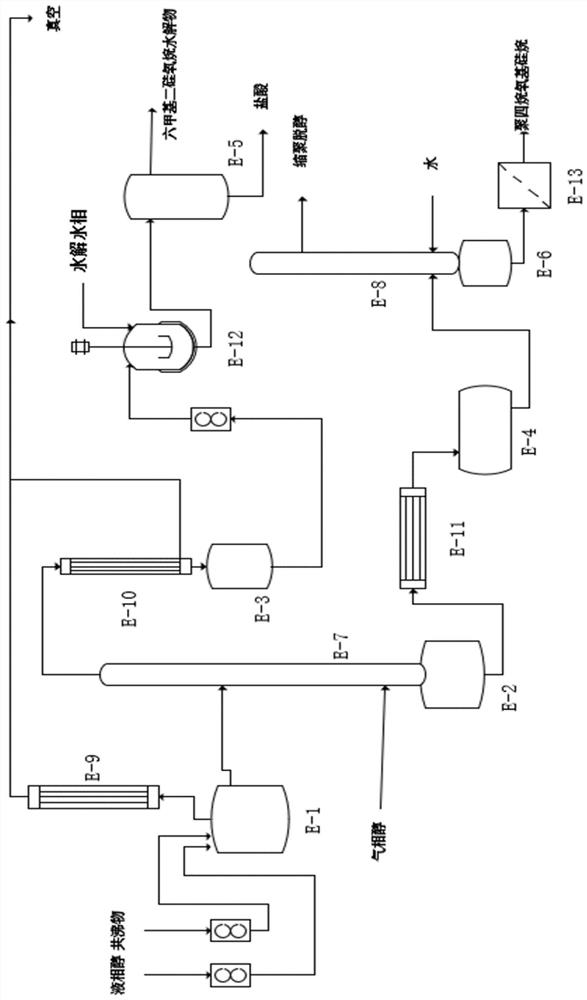

Image

Examples

Embodiment Construction

[0066] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0067] Unless otherwise stated, the raw materials and reagents used in the following examples are commercially available or can be prepared by known methods.

[0068] The azeotrope used in the embodiment consists of silicon tetrachloride content 30%, trimethylchlorosilane 65%, methyldichlorosilane 3.5%, tetramethylsilane 1.5% (synthesized by Jiangxi Lanxing Huo Silicone Co., Ltd. Provided by monomer fractionation unit).

[0069] The device used in the embodiment and its connection m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com