Deposit preform injection moulding device with additional magnetic filed

A technology of spray forming and external magnetic field, applied in the field of metal billet processing, can solve the problems of low yield of atomized molten metal and large conical expansion angle, so as to improve the quality of forming, save manufacturing costs and improve economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

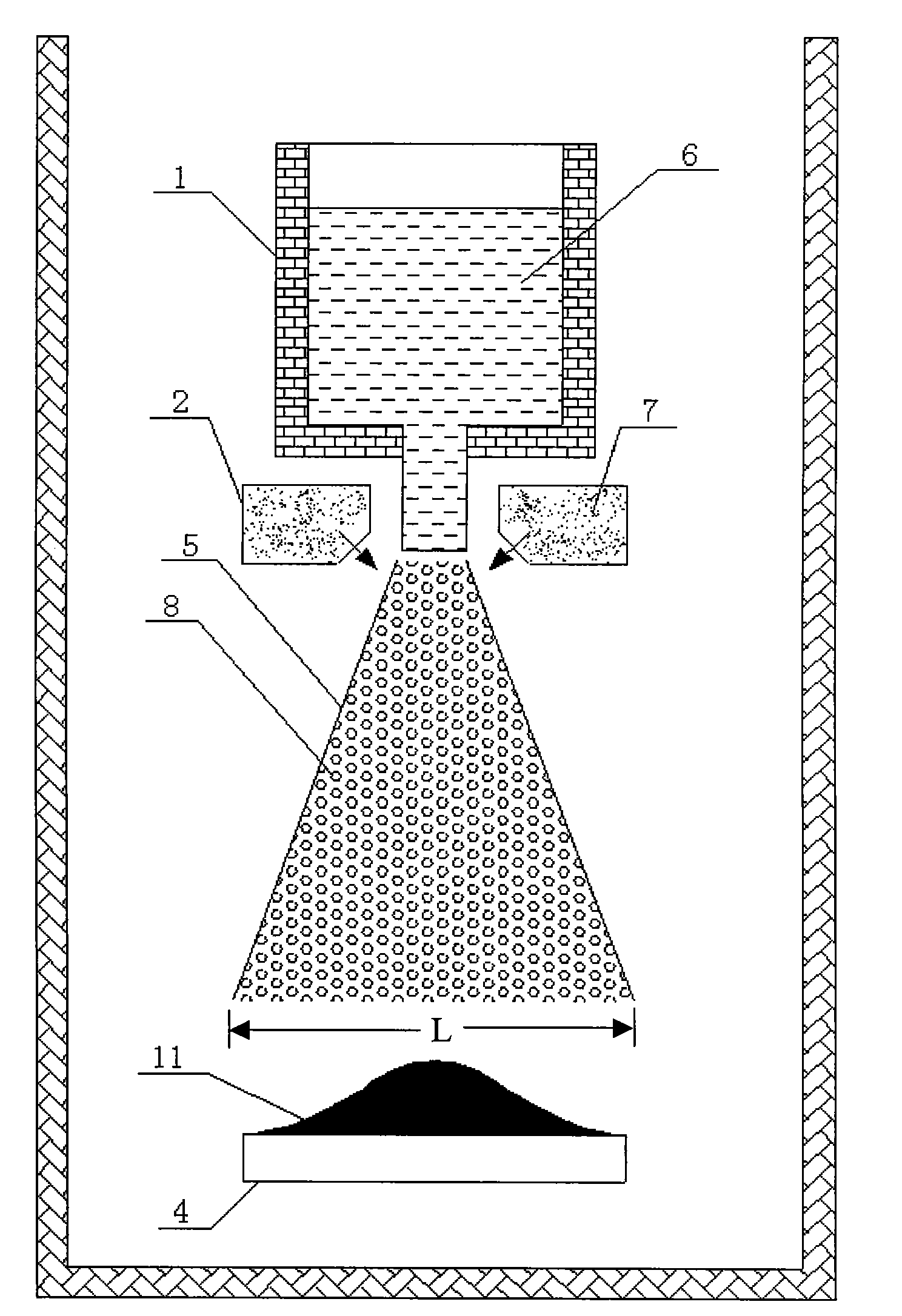

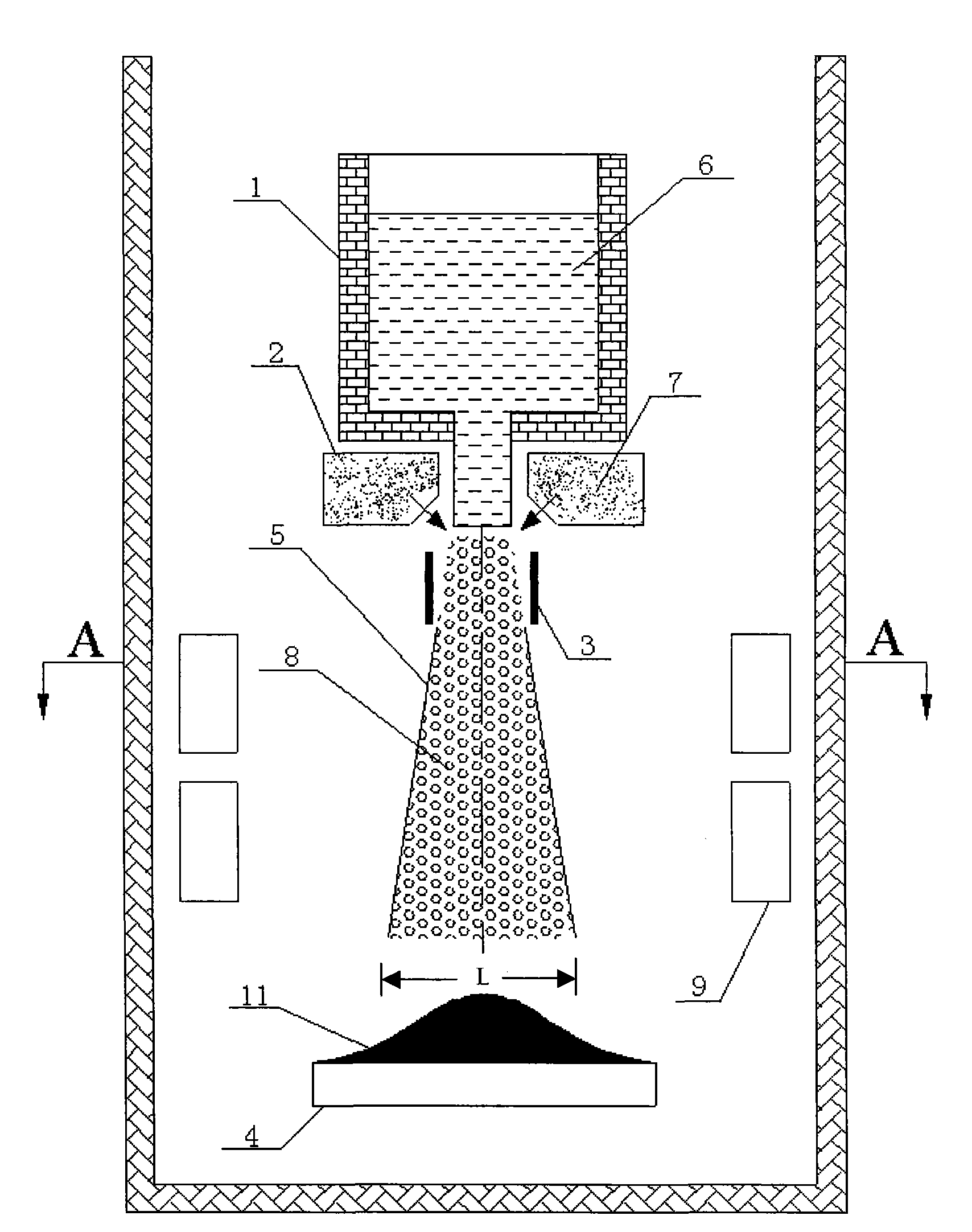

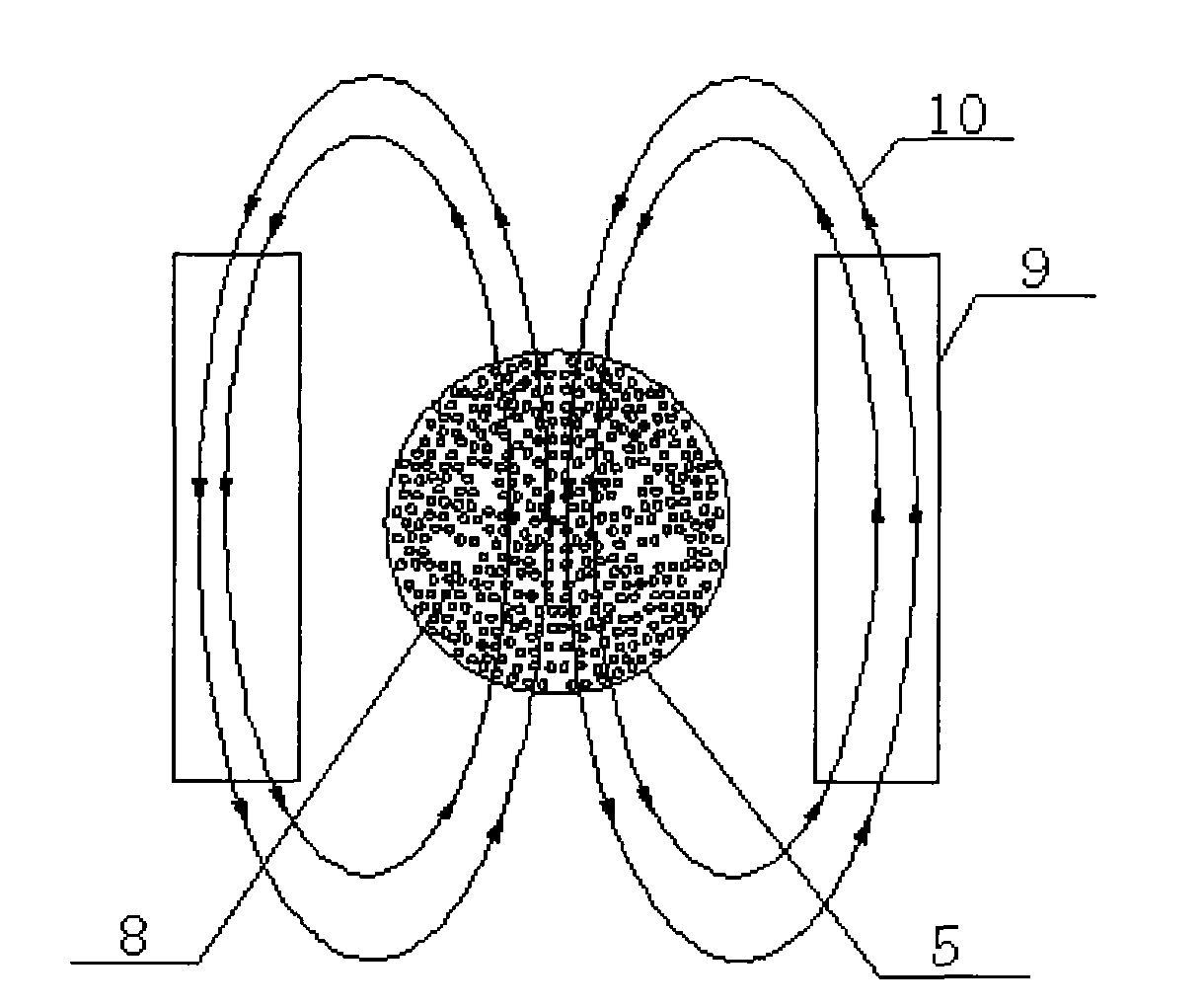

[0024] Such as figure 2 As shown, a deposition blank spray forming device with an external magnetic field includes a crucible 1, an atomizer 2, a charging electrode 3 and a depositor 4, and the crucible 1 and the atomizer 2 are communicated by a guide tube, The depositor 4 is located below the outlet of the atomizer nozzle, the atomized particle flight area 5 is between the atomizer nozzle and the depositor, the molten metal 6 is installed in the crucible 1, and the atomizer 2 is filled with high-pressure nitrogen gas 7, so The charging electrode 3 is located at the breaking point where the molten metal 6 is separated into atomized particles 8, and a magnetic field generating device 9 is installed around the atomized particle flying area 5, and the magnetic field generating device is located below the charging electrode. Described magnetic field generating device 9 is two energized electromagnetic coils symmetrically arranged on both sides of the atomized particle flying area...

Embodiment 2

[0030] A spray-forming device for deposited blanks with an external magnetic field, comprising a crucible 1, an atomizer 2, a charging electrode 3 and a depositor 4, the crucible 1 and the atomizer 2 are connected by a guide tube, and the depositor 4 Located below the outlet of the atomizer nozzle, between the atomizer nozzle and the depositor 4 is the atomized particle flight area 5, the molten metal 6 is installed in the crucible 1, and the atomizer 2 is filled with high-pressure helium gas 7, said The charging electrode 3 is located at the breaking point where the molten metal 6 is separated into atomized particles 8, and the atomized particle flying area 5 is externally provided with a circular magnetic field, and the axis of the magnetic field is the same as that of the atomized particle flying area. see Figure 5 . When the charging electrode 3 is a positive electrode, the atomized particles 8 are negatively charged, and the direction of the annular magnetic field is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com