Method of preparing titanium and titanium alloy using titanium containing furnace clinker

A technology for titanium slag and titanium alloy, which is applied in the field of preparing titanium metal by using titanium-containing slag, can solve the problems of reducing the hydration strength of cement, cannot use cement active admixtures, etc., and achieves the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A method for preparing titanium and titanium alloys by utilizing titanium-containing slag, the composition of the titanium-containing slag used is: 24.62wt% CaO, 24.62wt% SiO 2 27.97wt%, Al 2 o 3 13.40wt%, MgO 7.68wt%, Fe 2 o 3 3.19wt%, TiO 2 It is 20.59wt%, and MnO<1wt%. It is mixed with 0-40% metal aluminum, 0-50% carbon, 0-40% iron, and 0-20% magnesium. After mixing evenly, it is melted in a plasma furnace and undergoes thermal reduction reaction to obtain titanium and titanium alloy.

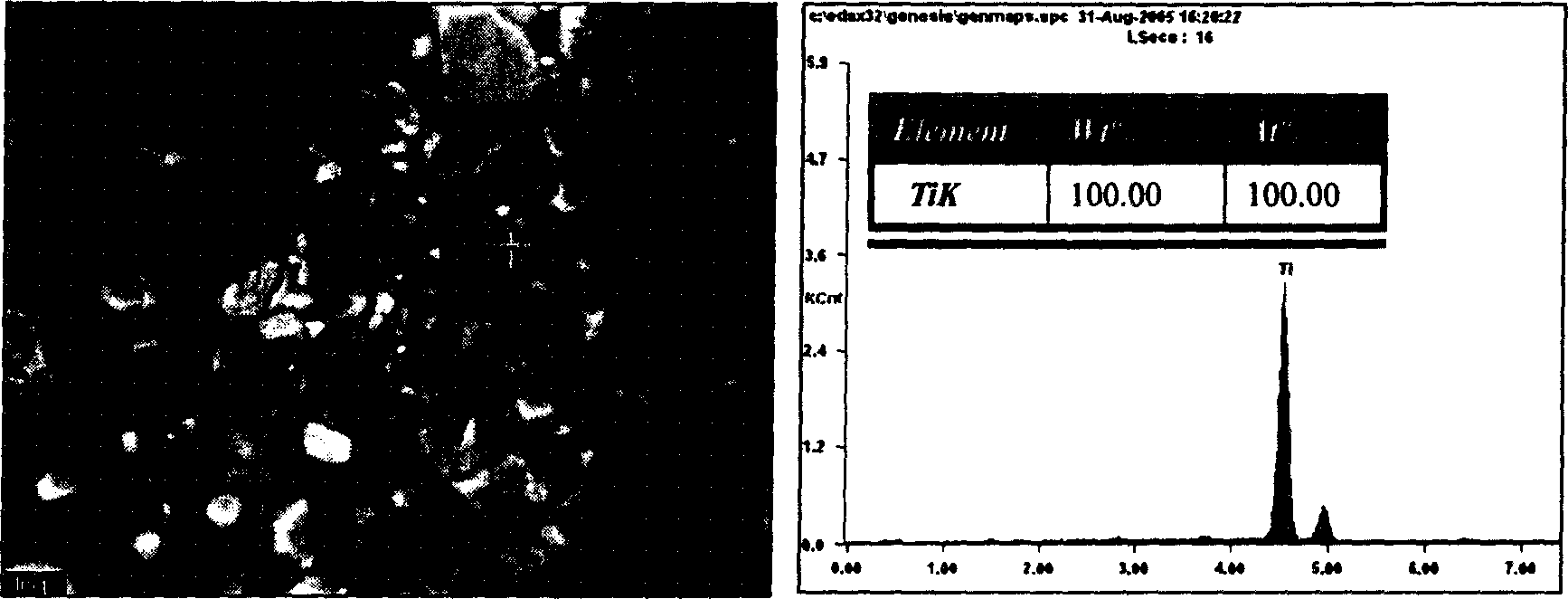

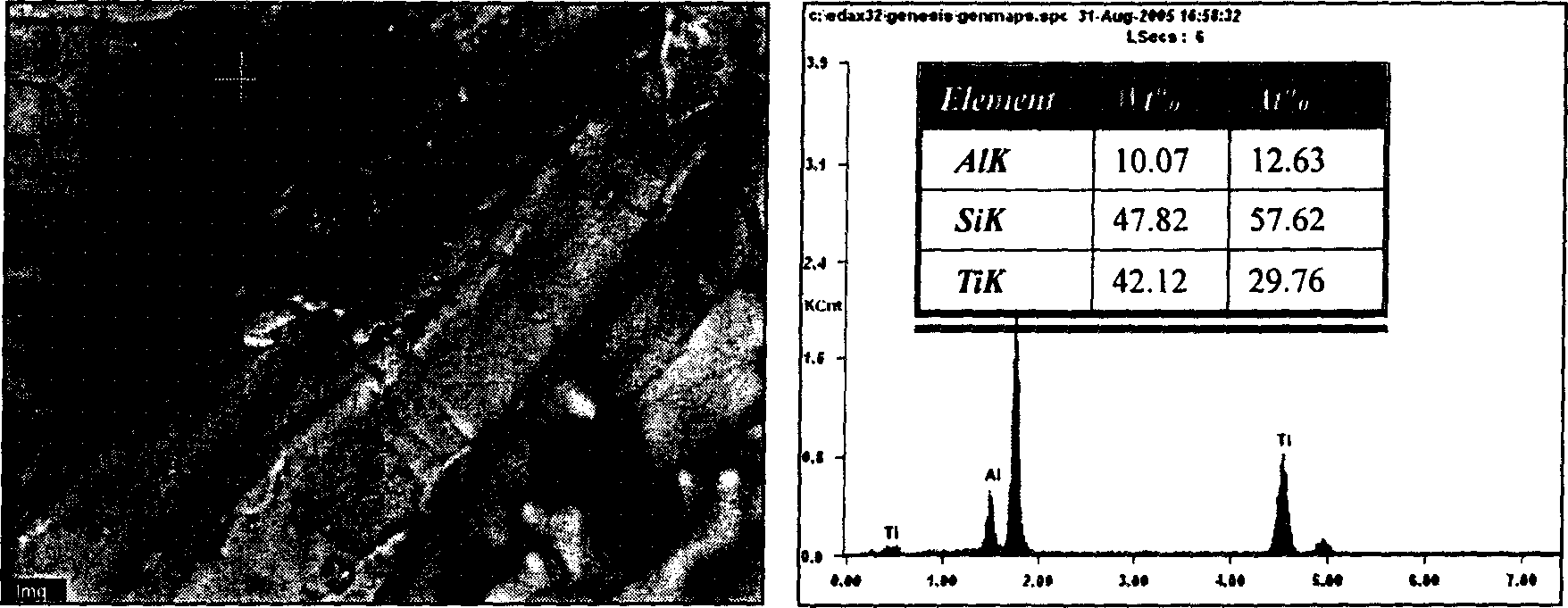

[0012] The prepared reduction product of the present embodiment-metal titanium such as figure 1 As shown, the prepared reduction product-Al-Si-Ti alloy is as follows figure 2 shown. The obtained product was analyzed by energy spectrometer for microstructure and microregion composition, and the analysis results were as follows: figure 1 , figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com