Method for generating nitrogenous ferrovanadium alloy through utilizing ferrovanadium electric-arc furnace

An electric arc furnace and ferroalloy technology, applied in the field of ferroalloy production, can solve the problems of high production energy consumption, high production technology threshold, low production efficiency and output, etc. Effect

Active Publication Date: 2013-06-26

UNIV OF SCI & TECH BEIJING +1

View PDF4 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing production technology threshold of vanadium nitride or ferrovanadium nitride is relatively high, and a large number of solid-state nitriding methods are used, the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

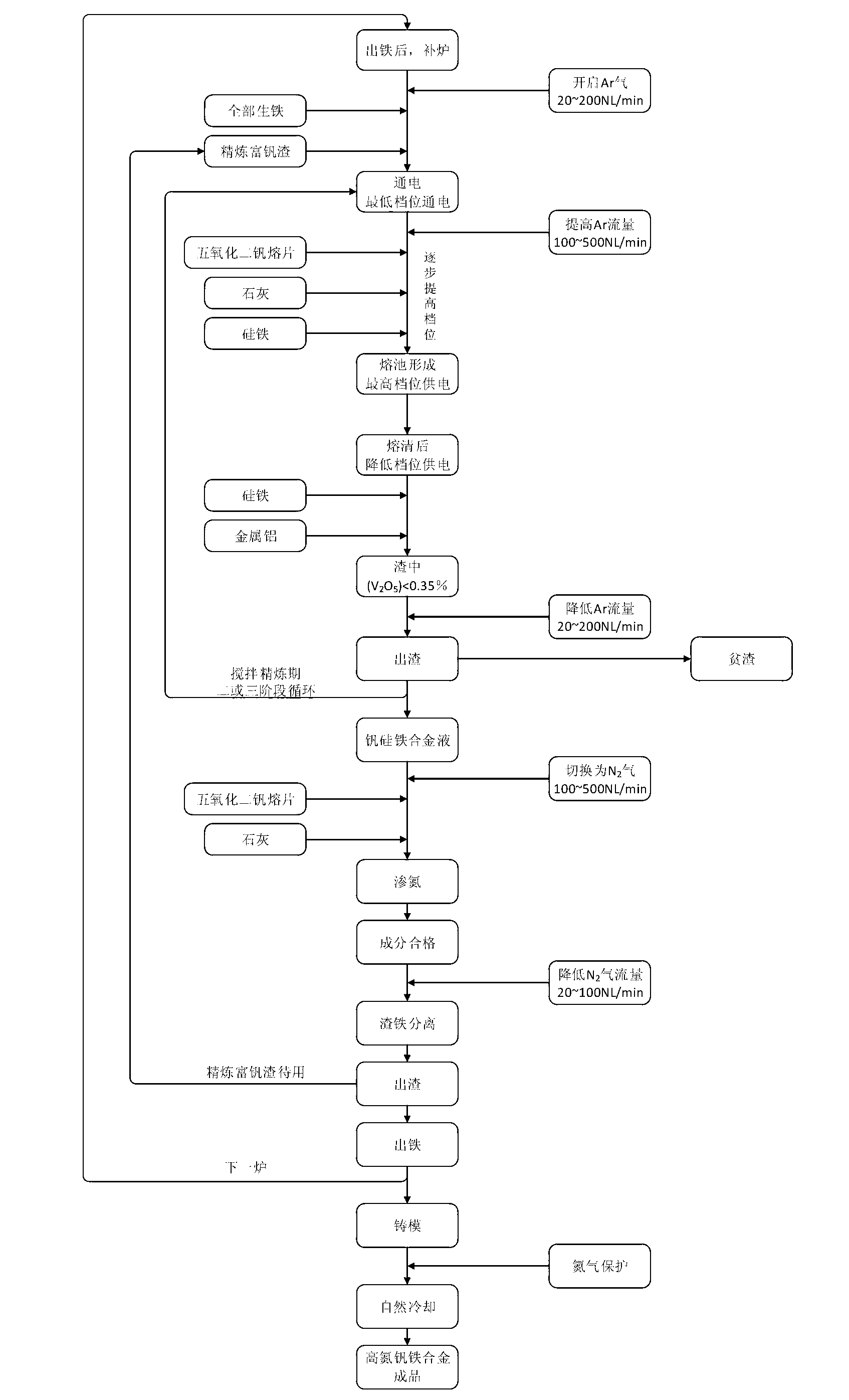

The invention discloses a method for generating nitrogenous ferrovanadium alloy through utilizing a ferrovanadium electric-arc furnace, and belongs to the technical field of non-ferrous metal metallurgy. The method is characterized in that a single or more nitrogen/argon blowing devices are installed on the furnace bottom or the furnace wall of the ferrovanadium electric-arc furnace with the general nominal capacity of 300-5000kg and can freely blow nitrogen/argon into a ferrovanadium electric-arc furnace hearth, selected raw materials are used, and finally, the nitrogenous ferrovanadium alloy with 45-60% of V, less than 2% of Si and 2-8% of N can be obtained and can be used as a steel additive. Compared with common ferrovanadium, according to the nitrogenous ferrovanadium alloy, the alloy usage can be reduced above 10%, the vanadium yield is increased by 1%, the melting period is shortened by above 30 minutes, the melting power consumption is reduced by 10-15%, and the comprehensive melting cost is lowered by above 2%.

Description

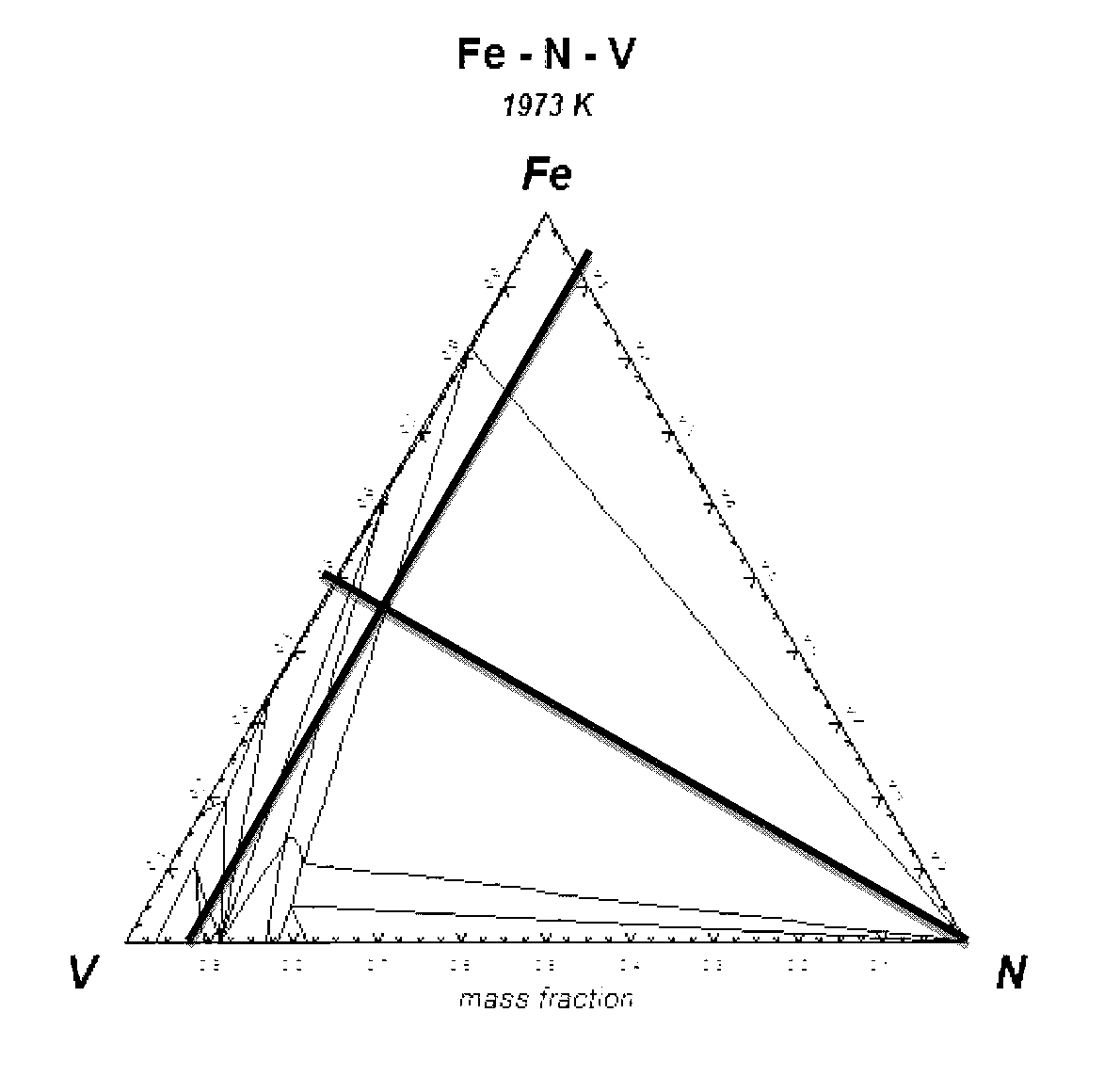

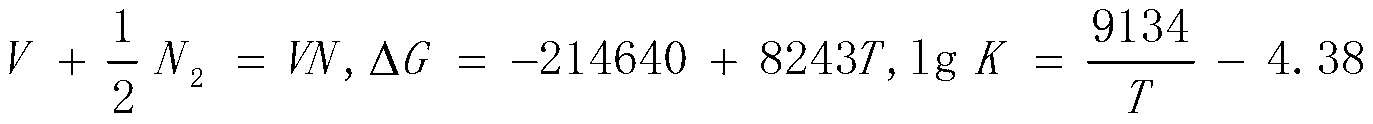

technical field [0001] The invention relates to a method for producing nitrogen-containing ferro-vanadium alloy by using an ordinary ferro-vanadium electric arc furnace, belongs to the technical field of non-ferrous metal smelting, and is a ferroalloy production method. technical background [0002] Vanadium is an important alloying element in the steel industry. More than 85% of vanadium in the world is used in steel production. The interaction of vanadium with nitrogen and other elements in steel can improve many properties of steel. [0003] The vanadium-containing raw materials used in the iron and steel industry mainly include ferrovanadium, vanadium nitride, and ferrovanadium nitride. [0004] Ferro-vanadium alloy, whose main components are vanadium and iron, is the most productive vanadium product. Ferrovanadium production generally uses ferrovanadium electric arc furnaces, using vanadium oxides as raw materials, and producing according to methods such as silicotherm...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C35/00C22C33/04C22C1/02C22C1/10C22C27/02C22C38/12

Inventor 董凯朱荣白瑞国刘文娟李东明

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com