Method for preparing microalgae grease through mixed cultivation

A technology of mixed culture and microalgae oil, which is applied in the field of biotechnology and bioenergy, can solve the problems of unfavorable algae absorption and utilization, no oil content involved, and lower carbon fixation efficiency, so as to alleviate the greenhouse effect and exhaust gas pollution, and suppress miscellaneous The growth of bacteria and the effect of improving carbon sequestration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

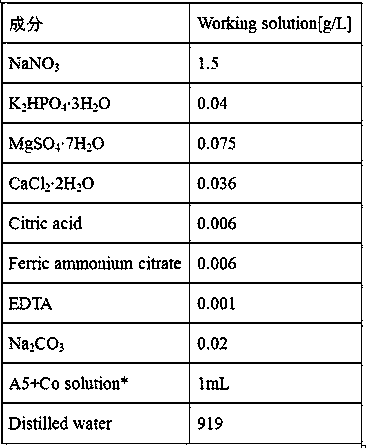

[0022] The preparation process of the microalgae seed solution of the present invention is as follows: the microalgae culture adopts BG11 medium, and the formulation of the medium is shown in Table 1 and Table 2.

[0023] Table 1 BG11 medium

[0024]

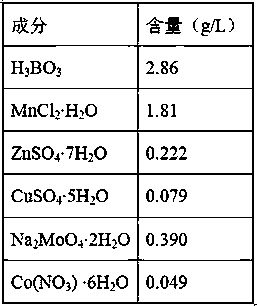

[0025] *Table 2 Composition of A5+Co solution in Table 1

[0026]

[0027] First, prepare BG11 liquid medium according to Table 1 and Table 2, adjust the pH of the medium for cultivating Pseudochlorella kesserii FSH-Y3 and Scenedesmus obliquus FSH-Y2 to 10, and adjust the pH of the medium for cultivating Chlorella keserii SF-B1 The pH of the medium was adjusted to 8.0, and then Pseudochlorella kescherei FSH-Y3, Scenedesmus obliquus FSH-Y2, and Chlorella SF-B1 were inoculated in the above-mentioned medium respectively. Cultivate in a constant temperature light shaker, the culture temperature is 25°C, the light cycle is 24h, the light-dark time ratio is 14:10, the light intensity is 5000Lux, 120rpm shaking culture until the...

Embodiment 1

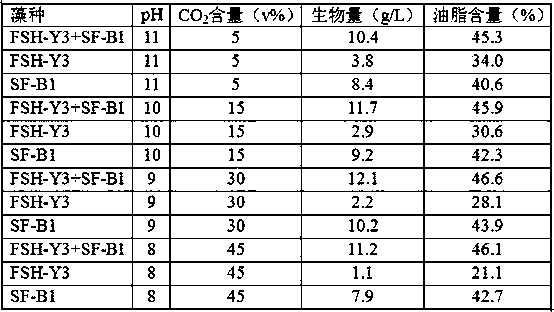

[0029]The prepared microalgae seed liquids were respectively inoculated in BG11 medium to produce microalgae oil. In a 20L air-lift photobioreactor, the seed liquid of Pseudochlorella kesperi FSH-Y3 and the seed liquid of Chlorella SF-B1 were inoculated according to the volume ratio of 1:1, and the total inoculation amount of 20% was inoculated to In the BG11 medium, the pH value is controlled between 8 and 11, and a mixed gas of nitrogen and carbon dioxide is introduced, the carbon dioxide content is 5v% to 45v%, the light intensity is 5000Lux, the culture temperature is 20°C, and the light cycle is 24h. The light to dark time ratio is 14:10. After cultivating for 7 days, it is in a stable period. After cultivating, the algae liquid is collected by centrifugation, vacuum freeze-dried to constant weight at -60°C, and then the dry weight of the algae powder is measured to calculate the biomass production, which is measured by the n-hexane:ethyl acetate method The total lipid c...

Embodiment 2

[0034] The prepared microalgae seed liquids were respectively inoculated in BG11 medium to produce microalgae oil. In a 20L airlift photobioreactor, Scenedesmus obliquus FSH-Y2 seed liquid and Chlorella SF-B1 seed liquid were inoculated at a ratio of 1:1 by volume, and were inoculated to BG11 at a total inoculum of 20%. In the medium, the pH value is controlled between 8 and 11, and a mixed gas of nitrogen and carbon dioxide is introduced, the carbon dioxide content is 5v% to 45v%, the light intensity is 5000Lux, the cultivation temperature is 20°C, the light cycle is 24h, and the light is dark. The time ratio is 14:10. After cultivating for 7 days, it is in a stable period. After cultivating, the algae liquid is collected by centrifugation, vacuum freeze-dried to constant weight at -60°C, and then the dry weight of the algae powder is measured to calculate the biomass production, which is measured by the n-hexane:ethyl acetate method The total lipid content, the results are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com