Forging process for adopting centrifugal casting hollow ingots to produce ring-shaped parts and cylindrical parts

A technology of centrifugal casting and hollow ingot, which is applied in the field of forging, can solve the problems of many blanks, multiple firing times, and low material yield, and achieve the effects of reducing energy consumption, reducing energy consumption, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: The present invention will be further described by taking the forging test of a 316LN stainless steel cylinder used in a certain nuclear power plant as an example.

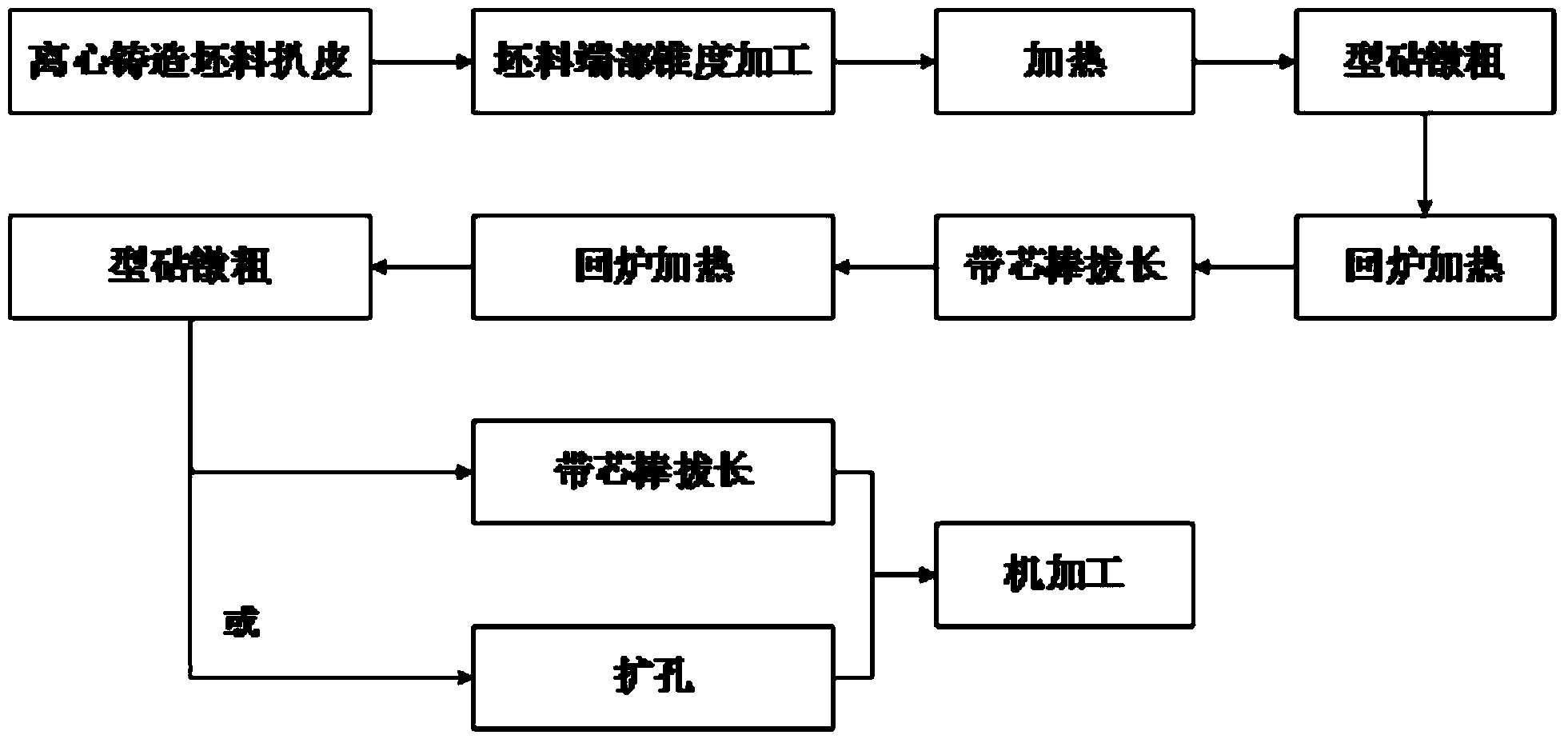

[0024] Such as figure 1 Shown, be the technical process block diagram of the present invention and its implementation example, specifically comprise the following process steps:

[0025] In the first step, after the chemical composition analysis, peeling of the inner and outer surfaces of the pipe as required, processing of pipe end taper and flaw detection, the centrifugally cast hollow ingot with a weight of about 1045kg and a size of Φ480×115×1000mm is sent into the After removing the residual oxides, the furnace is heated according to the six-stage heating curve (the holding time of each stage decreases and the heating speed increases). The furnace entry temperature is 700°C, and the maximum heating temperature is 1180°C.

[0026] The six-stage heating curve refers to: the temperature ri...

Embodiment 2

[0033] Embodiment 2: The present invention will be further described by taking the forging test of a 316LN stainless steel cylinder used in a certain nuclear power plant as an example.

[0034] In the first step, after the chemical composition analysis, peeling of the inner and outer surfaces of the pipe as required, processing of pipe end taper and flaw detection, the centrifugally cast hollow ingot with a weight of about 1045kg and a size of Φ480×115×1000mm is sent into the After removing the residual oxides, the furnace is heated according to the six-stage heating curve (the holding time of each stage decreases and the heating speed increases). The furnace entry temperature is 700°C, and the maximum heating temperature is 1180°C.

[0035] The six-stage heating curve refers to: the temperature rise of the cold ingot below 700°C is regarded as the first stage, the heat preservation at 850°C is regarded as the second stage, and the heating from 850°C to 950°C is regarded as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com