Inclusion control method for pipeline welding wire steel

A control method and welding wire steel technology, which is applied in the field of iron and steel smelting, can solve the problems of long stirring time and large amount of oxidation, and achieve the effect of increasing yield and reducing the size of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below by way of examples.

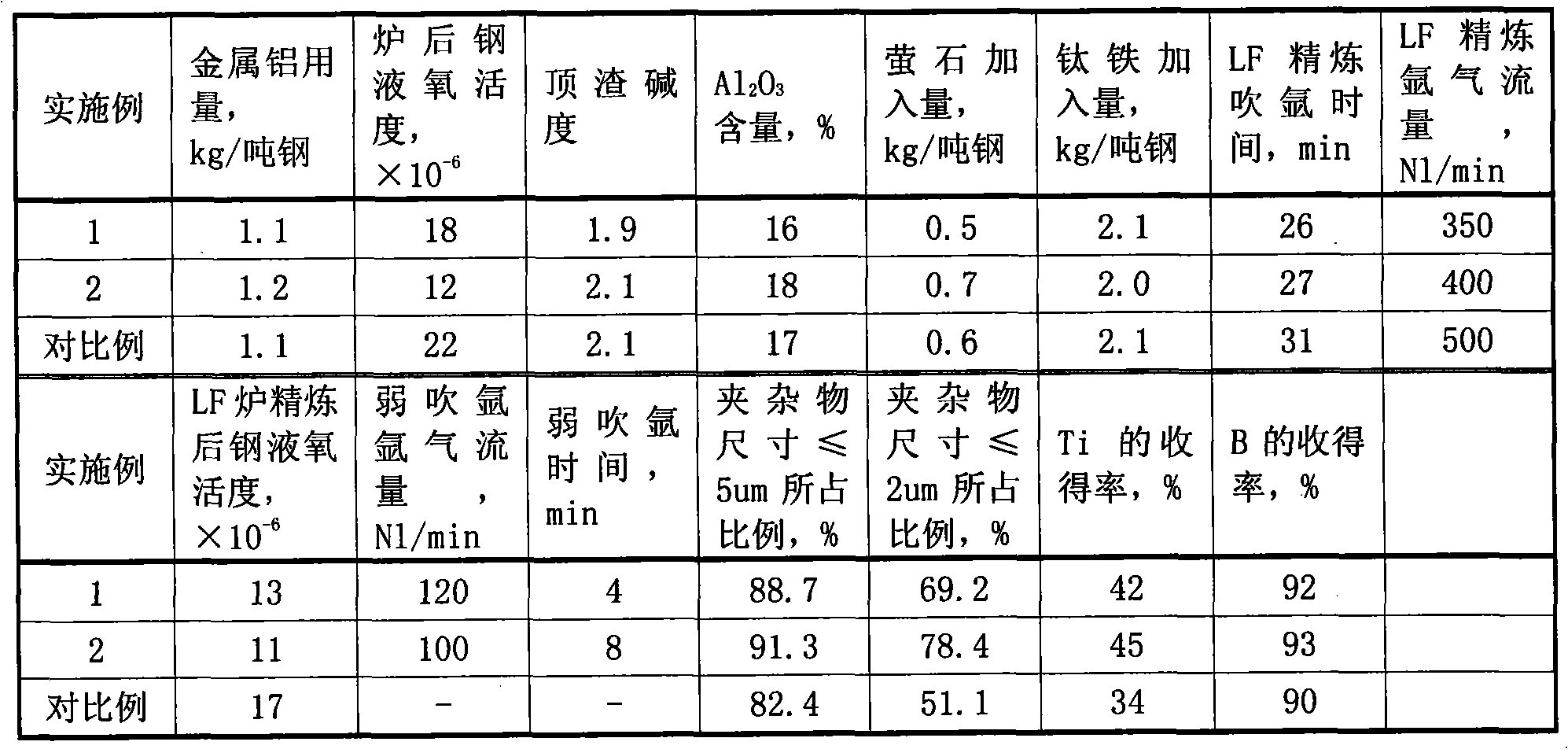

[0011] The steel grade of the embodiment of the present invention is AH70G. See Table 1 for the process parameters and effects of the method for controlling inclusions in pipeline welding wire steel according to the embodiment of the present invention. It is not difficult to see from Table 1 that compared with the common process, the size of the inclusions in the steel has been reduced by the control method of the present invention, and the yield of easily oxidized Ti, B and other elements in the steel has been improved.

[0012] Table 1 embodiment of the present invention process parameter and effect

[0013]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com