Recovery processing method for cyanogen golden mine tailing

A technology for recycling and processing gold tailings, applied in the direction of improving process efficiency, etc., can solve problems such as comprehensive utilization of tailings, ineffective recycling, and reduced economic benefits, so as to achieve good environmental and social benefits, improve the level of comprehensive utilization, The effect of enhancing the social image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

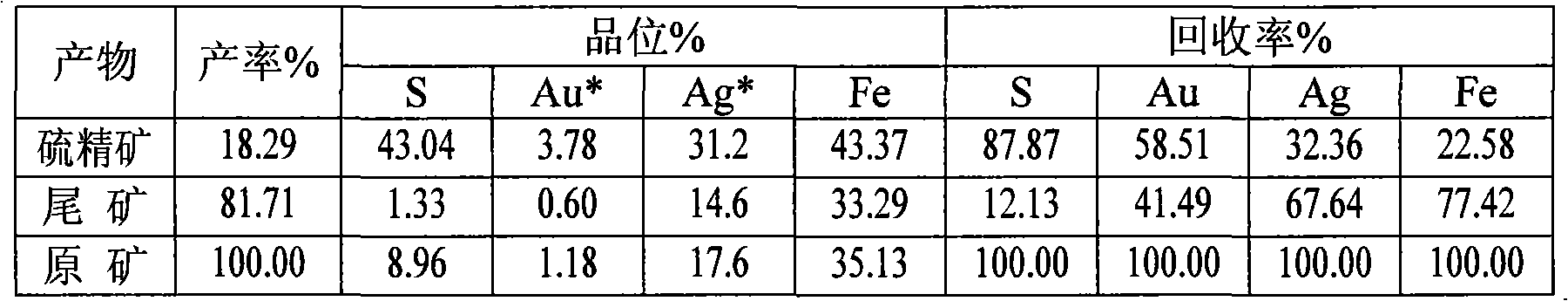

[0022] The raw ore of embodiment sorting is a kind of tailings after gold-containing oxidized ore cyanogen gold, wherein mainly contains valuable components such as iron, sulfur, gold, and its raw ore grade is:

[0023] Au 1.13g / t, Ag 17.70g / t, TFe 34.30%, S 8.79%.

[0024] First adjust the pulp concentration to 18-20%, then add activator H 2 SO 4 1000g / t and CuSO 4 300g / t, add collector (butyl xanthate + diesel oil) (1:1) 200g / t, foaming agent 2 # Oil 30g / t is used for sulfur roughing, and the sulfur rough concentrate obtained by roughing is subjected to a blank beneficiation; after sulfur roughing, two sweeps are carried out, and the dosage of the first sweeping agent is: activator CuSO 4 100g / t, collector (butyl xanthate + diesel oil) (1:1) 200g / t, foaming agent 2 # The oil is 10g / t, and the agent dosage for the second sweep is: collector butyl xanthate 20g / t. The closed-circuit selection results are shown in Table 2:

[0025] Table 2:

[0026]

[0027] * Note:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com