Aluminum silicate thread throwing fiber board and manufacturing method thereof

A silk fiber, aluminum silicate technology, applied in fiber processing, filament/thread forming, textile and papermaking, etc., can solve problems such as limited use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

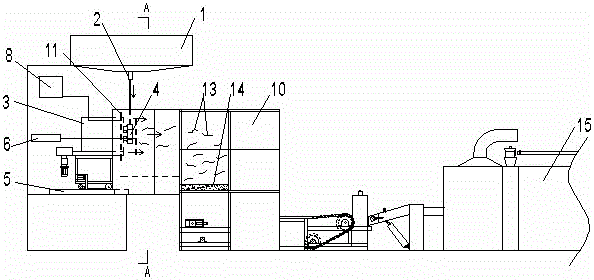

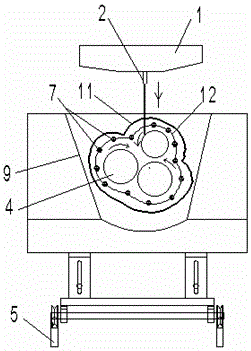

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] Such as figure 1 , figure 2 As shown, the preparation process of aluminum silicate fibrous fiberboard is to use resistance furnace to melt raw materials. When the molten pool meets the process requirements, the molten liquid will form a stable stream through the orifice, and the filaments will be formed into fibers by spinning rollers. Chemical sizing, so that the binder is evenly distributed on the fiber, and then the cotton is settled and collected by the cotton collector, and then enters the drying oven to be solidified and formed, and finally cut and formed according to customer needs. Specific steps are as follows:,

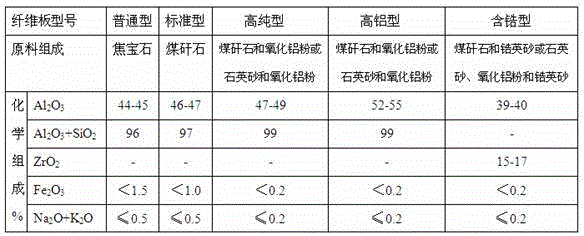

[0027] Step a, resistance furnace melting material: select raw materials according to product process requirements or customer needs, and can produce different types of fiberboards. Fiberboards can be divided into ordinary fiberb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com